china stick welding stainless factories

The Rise of China’s Stick Welding Stainless Steel Factories

Stick welding, also known as Shielded Metal Arc Welding (SMAW), has been a fundamental process in the fabrication and repair industries for many years. With its simplicity and versatility, this welding technique has gained significant traction in China, especially in the stainless steel sector. As the demand for stainless steel products grows, so too does the number of factories specializing in stick welding stainless steel across the country. This article explores the emergence of these factories, their significance, and the future of stick welding in China.

A Growing Industry

China has established itself as a global leader in stainless steel production, accounting for a major portion of the world’s output. This expansive growth has been fueled by the country's rapid industrialization and urbanization, leading to increased demand for stainless steel in various applications, including construction, automotive, and manufacturing.

As industries expanded, the necessity for efficient and reliable welding processes became evident. Stick welding presents an effective solution, particularly for stainless steel, due to its ability to produce strong and durable joints. This has led to an increasing number of factories adopting stick welding techniques for their production lines.

Advantages of Stick Welding in Stainless Steel Applications

One of the primary advantages of stick welding is its flexibility. The process can be conducted in various environments, including remote locations or places with limited access to electricity. This is particularly pertinent in China, where many construction projects occur in challenging terrains. Additionally, stick welding equipment is generally more affordable than other welding technologies, making it accessible for smaller companies and workshops.

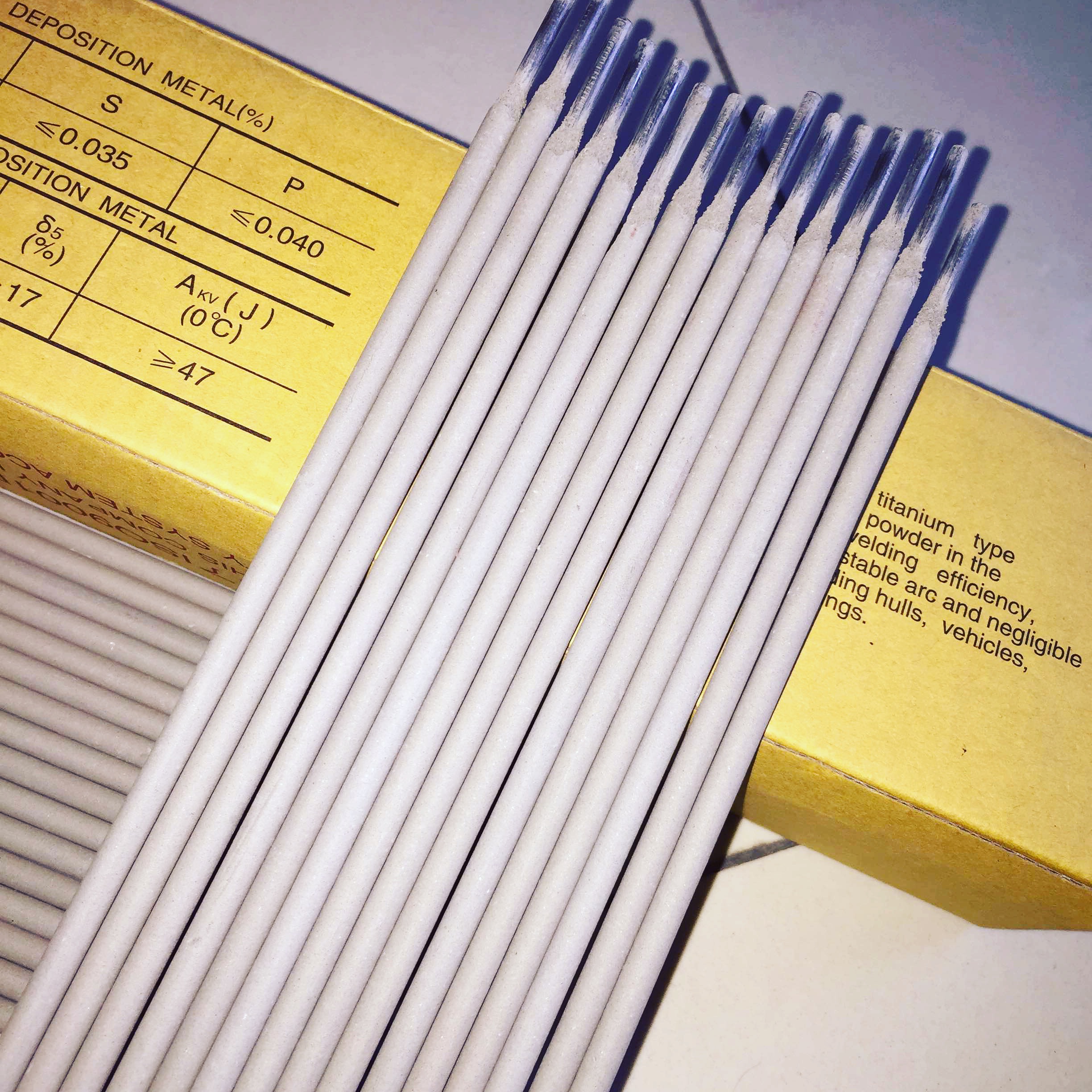

Stainless steel's unique properties, such as corrosion resistance and strength, coupled with stick welding’s outlining characteristics, make them an ideal match. The moderate heat produced by stick welding minimizes the risk of warping, which is crucial when working with thin stainless steel sheets. Furthermore, the ability to use various types of electrodes allows factories to achieve specific outcomes tailored to the targeted applications.

Quality and Innovation in Welding Technologies

china stick welding stainless factories

Chinese manufacturers are increasingly prioritizing quality and innovation within their stick welding practices. Modern stick welding machines are equipped with advanced features such as inverter technology, which enhances efficiency and lowers energy consumption. These machines facilitate better control over the welding process, resulting in superior weld quality, reduced spatter, and less need for cleanup.

Moreover, factories in China are embracing automation in their stick welding operations. Robotic arms equipped with stick welding torches can perform welding tasks with precision and consistency, thereby increasing productivity and reducing human error. As factories adapt to new technologies, the output quality of stainless steel products improves, solidifying China’s reputation in the global market.

Environmental Considerations

With increased industrial activities come heightened environmental concerns. Thankfully, many modern stick welding methodologies are designed with sustainability in mind. Factories are adopting practices to reduce waste and emissions associated with welding processes. For instance, the selection of eco-friendly electrodes and efficient energy use during welding can lower the environmental impact of stick welding operations.

Furthermore, there is a growing awareness of the importance of proper training for welders. Educational programs focused on sustainable welding practices ensure that workers are equipped with the knowledge and skills to minimize their environmental footprint while maximizing efficiency.

Future Prospects

The outlook for stick welding stainless steel factories in China appears promising. As the country continues to evolve as an industrial hub, stick welding will play a pivotal role in addressing the increasing demand for versatile and durable materials. With advancements in technology, a focus on quality, and a commitment to sustainable practices, these factories are well-positioned to meet the challenges of the future.

In conclusion, the rise of stick welding stainless steel factories in China represents a significant trend in the industrial sector. Through innovation, quality assurance, and environmental considerations, these factories are not only contributing to China’s status as a leading manufacturer but are also setting benchmarks for the global welding industry. As this sector continues to grow, it will undoubtedly influence welding practices worldwide, shaping the landscape of manufacturing for years to come.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025