China E318 Welding Electrode Manufacturer for High-Quality Welding Solutions and Services

The Rise of China’s E318 Welding Electrode Manufacturers

In the realm of industrial manufacturing and construction, welding plays a critical role, serving as the backbone for assembling metals in myriad applications. Among the various welding electrodes available, the E318 welding electrode has gained significant attention due to its versatility and efficiency in welding stainless steel. In this context, China has emerged as a prominent player in the production of E318 welding electrodes, positioning itself as a leading manufacturer in the global market.

Understanding E318 Welding Electrodes

E318 welding electrodes are designed for welding austenitic stainless steel. They are particularly known for their excellent corrosion resistance, high ductility, and good weldability. The designation E318 means that the electrode can be used in various environments, including those that require resistance to both oxidizing and reducing conditions. This makes it ideal for industries such as petrochemical, food processing, and pharmaceuticals, where hygiene and durability are paramount.

These electrodes contain a carefully balanced composition of elements such as chromium, nickel, and molybdenum, which enhances their performance during the welding process. They are available in different diameters and lengths, making them suitable for a range of applications, from thin sheet metal to thicker plates.

The Manufacturing Landscape in China

China's ascent as a manufacturer of E318 welding electrodes can be attributed to several factors. First and foremost, the country has significantly invested in its industrial capabilities, boasting advanced manufacturing technologies and processes. This investment has enabled Chinese manufacturers to produce high-quality welding electrodes that meet international standards.

Moreover, China's massive production capacity allows it to scale operations effectively, meeting the growing global demand for welding electrodes. The country's proximity to essential raw materials and a well-developed logistics network further enhance its competitive edge. Cost efficiencies resulting from lower labor costs also allow Chinese manufacturers to offer competitive pricing, making their products attractive to international buyers.

Quality Standards and Certification

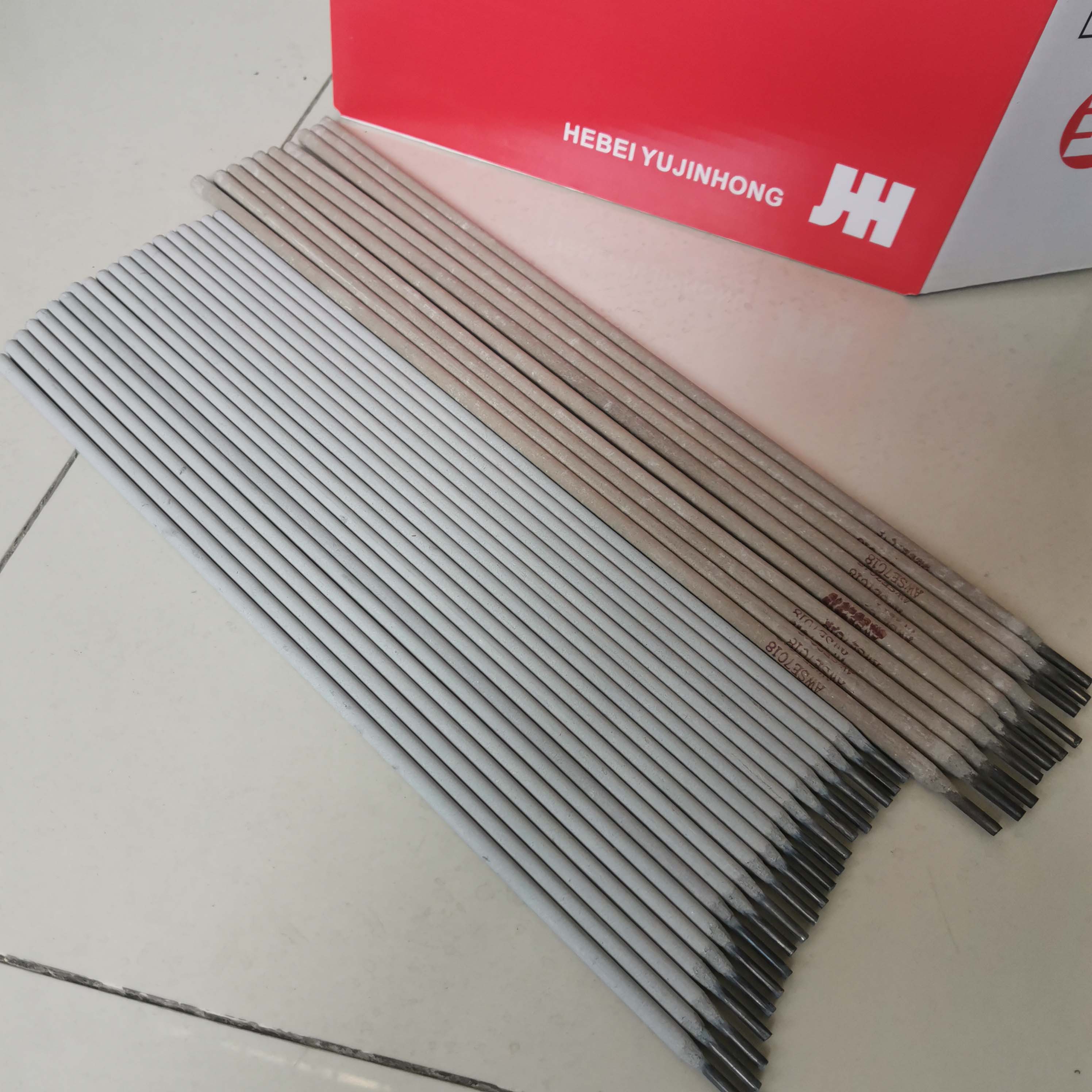

china welding electrode e318 manufacturer

To ensure that E318 welding electrodes produced in China meet stringent quality criteria, many manufacturers adhere to international certifications such as ISO 9001 and the American Welding Society (AWS) standards. These certifications are crucial not only for domestic compliance but also for gaining the trust of global customers.

Chinese manufacturers often conduct rigorous quality control tests in their production processes, ensuring that the final products have desirable properties such as tensile strength, ductility, and consistent chemical composition. This commitment to quality has helped Chinese E318 welding electrodes gain acceptance in various industrial sectors worldwide.

Challenges and Opportunities

Despite its strengths, the Chinese welding electrode industry faces challenges. The global market is becoming increasingly competitive, with manufacturers from Europe, the United States, and other regions striving to enhance their offerings. Additionally, concerns related to environmental sustainability and compliance with stricter regulations can pose significant challenges for manufacturers.

However, these challenges also present opportunities for growth and innovation. Many Chinese manufacturers are investing in research and development to produce eco-friendly welding electrodes and exploring alternatives to traditional materials. Furthermore, the ongoing advancements in welding technologies, such as the rise of automation and robotics, offer avenues for improving efficiency and reducing costs.

Future Prospects

The future of China's E318 welding electrode manufacturing appears promising. As global industries continue to expand, the demand for high-quality welding materials is expected to rise. Chinese manufacturers, leveraging their expertise and production capabilities, are well-positioned to capture significant market shares in emerging economies.

Moreover, China's Belt and Road Initiative is likely to further enhance opportunities for Chinese manufacturers by facilitating international trade and cooperation, allowing for greater penetration into foreign markets.

In conclusion, as a leading manufacturer of E318 welding electrodes, China stands at the forefront of the global welding industry. With a commitment to quality, innovation, and competitive pricing, Chinese manufacturers are set to play a pivotal role in meeting the evolving needs of industries that rely on welding as a fundamental process. As they navigate challenges and seize opportunities, the Chinese welding electrode sector is poised for substantial growth in the coming years.

-

Wholesale E6013 Welding Electrodes Factories Durable & AffordableNewsMay.18,2025

-

SG2 TIG Welding Wire 2.4mm - High Durability & Precision Welding SolutionNewsMay.18,2025

-

High-Quality 025 Flux Cored Welding Wire Wholesale Factory & SupplierNewsMay.18,2025

-

Gasless Stainless Steel MIG Welding Wire High-Quality Flux-Core SolutionNewsMay.17,2025

-

E6011 Welding Rod Meaning High Penetration & Versatile UseNewsMay.17,2025

-

High-Quality CS to SS Welding Electrodes 7016 Durable & Corrosion-ResistantNewsMay.16,2025