china welding wire sg2 manufacturer

Exploring SG2 Welding Wire Manufacturers in China

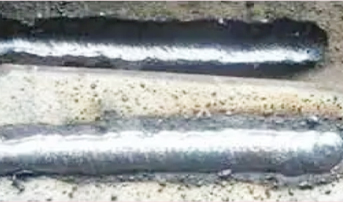

In the realm of welding, the choice of materials is pivotal in determining the quality and strength of welded joints. One such essential material is SG2 welding wire, a type of solid welding wire that is widely used in various industrial applications. As a critical component of the welding process, the demand for high-quality SG2 welding wire has led to the emergence of numerous manufacturers, particularly in China.

China has established itself as a global leader in the production of welding consumables, including SG2 welding wire

. With a combination of advanced manufacturing technologies, rigorous quality control standards, and competitive pricing, Chinese manufacturers have captured a significant portion of the international market.SG2 welding wire is primarily composed of mild steel and is designed for the gas metal arc welding (GMAW) process. This wire is characterized by its excellent arc stability, low spatter formation, and minimal post-weld clean-up. It is commonly used in the construction of structures, shipbuilding, automotive manufacturing, and various other applications where high tensile strength and ductility are crucial.

When searching for SG2 welding wire manufacturers in China, there are several aspects to consider. First, quality assurance is critical; reputable manufacturers will often adhere to international standards such as ISO 9001, ensuring that their products meet or exceed industry requirements. Additionally, examining the manufacturer's production capabilities and technologies can provide insights into the consistency and reliability of their products.

china welding wire sg2 manufacturer

Another key consideration is the range of products offered. While SG2 welding wire is widely sought after, manufacturers that offer a complete lineup of welding wires and related consumables can better cater to diverse customer needs. This includes variations in wire diameters, spool sizes, and packaging options.

Furthermore, assessing the manufacturer's export experience is essential, as this indicates their capability to handle international orders and their familiarity with global market standards. Engaging with suppliers who have a solid track record in exporting welding products can streamline the procurement process and mitigate potential challenges.

Lastly, price competitiveness is also a factor to consider. While lower costs can be attractive, it is essential to balance pricing with quality to avoid compromising the integrity of welding projects.

In conclusion, with a robust manufacturing infrastructure and an increasing focus on quality and innovation, Chinese manufacturers of SG2 welding wire are well-positioned to meet the demands of various industries. By conducting thorough research and selecting reputable suppliers, businesses can secure high-quality welding materials that enhance their production processes and overall project outcomes.

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025