electrodos de soldadura e6013 factories

Understanding E6013 Welding Electrodes and Their Manufacturing

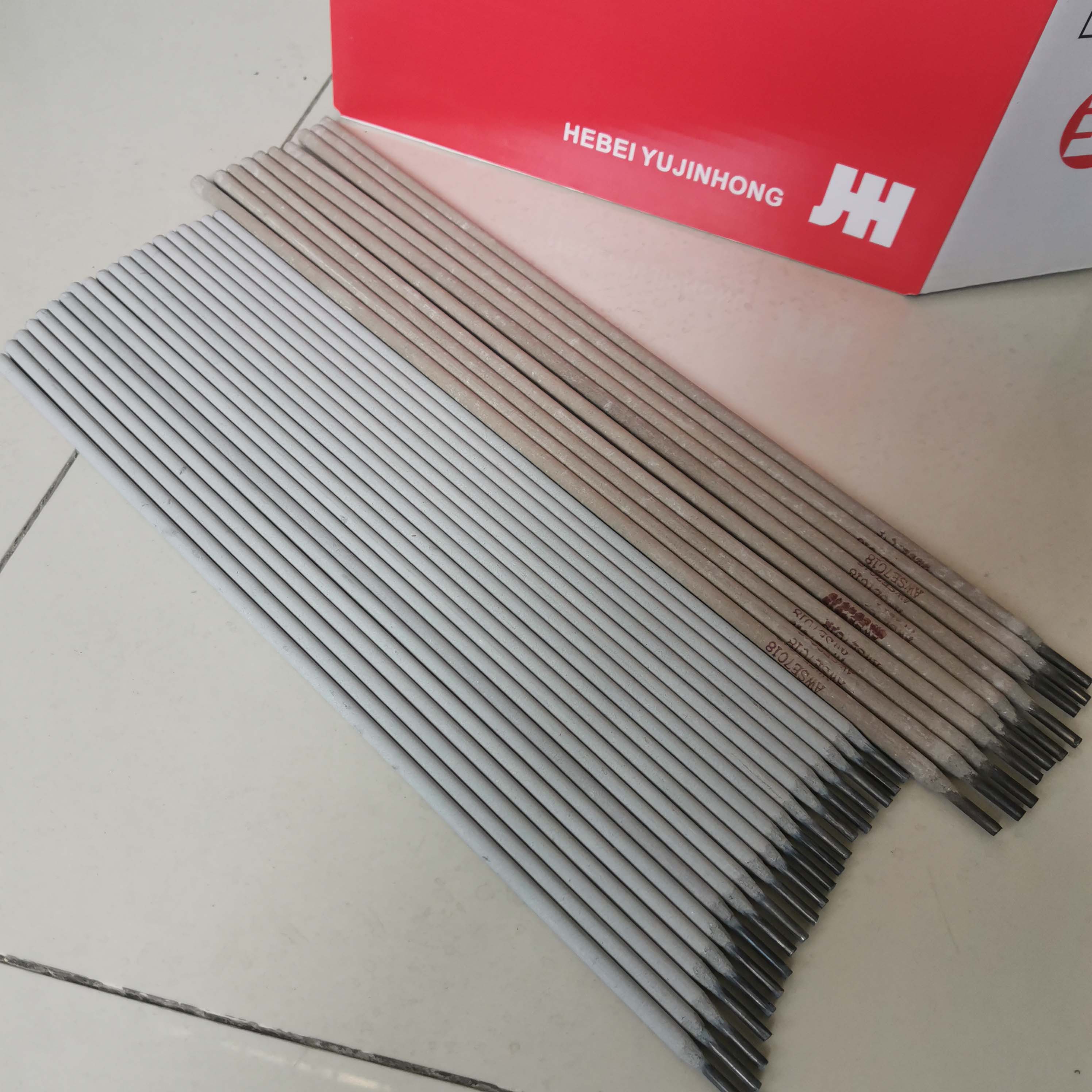

Welding plays a crucial role in various industrial applications, from construction to automotive manufacturing. Among the many types of welding electrodes available, E6013 is particularly popular due to its versatility and ease of use. This article explores E6013 welding electrodes, their characteristics, and the manufacturing processes involved in their production.

What is E6013?

E6013 is a type of consumable welding electrode commonly used in shielded metal arc welding (SMAW). The E in its designation indicates that it is an electrode used in welding, while 60 signifies that it can withstand a minimum tensile strength of 60,000 psi. The 1 denotes the type of welding positions it can be used for, which includes flat, horizontal, vertical, and overhead, making it a versatile choice for welders. The 3 indicates that it has a medium penetration, making it suitable for various applications.

Characteristics of E6013 Electrodes

E6013 electrodes are known for their exceptional welding abilities. They produce a stable arc, which enhances the manipulation and control during welding. This electrode type is suitable for both novice and experienced welders, as it offers excellent forgiveness in terms of technique.

Another noteworthy characteristic is the smooth finish of the welds produced. The electrodes create less spatter compared to other types, which means less post-weld cleaning is required. Furthermore, the welding beads created are aesthetically pleasing, making E6013 an ideal choice for applications where appearance matters.

Manufacturing Process of E6013 Electrodes

The manufacturing of E6013 welding electrodes involves several critical steps, ensuring that the final product meets the necessary standards for quality and performance

.electrodos de soldadura e6013 factories

1. Raw Material Selection The primary raw material for E6013 electrodes is steel wire, which must meet specific chemical composition and purity criteria. This wire typically undergoes a cleaning process to remove any contaminants.

2. Coating Preparation The coating for E6013 electrodes is made from a blend of materials, including iron powder, rutile, and various additives that enhance the arc stability and reduce spatter. This mixture is carefully prepared and proportioned to ensure optimal electrode performance.

3. Wire Drawing The selected steel wire is drawn to the desired diameter, which is usually around 3.2 mm for E6013 electrodes. This process ensures uniformity in size and shape, which is crucial for consistent welding performance.

4. Coating Application The prepared coating is applied to the wire using various methods, such as extrusion or dipping. The coating must be even and properly adherent to ensure efficient welding.

5. Drying and Curing After coating, the electrodes are dried and cured, which solidifies the coating and ensures its durability during the welding process.

6. Quality Control Each batch of electrodes undergoes rigorous quality control checks, including tests for tensile strength, arc stability, and weld appearance. This ensures that only high-quality E6013 electrodes reach the market.

Conclusion

E6013 welding electrodes are a staple in the welding industry due to their versatility, ease of use, and high-quality weld results. Their manufacturing process involves meticulous steps that ensure each electrode meets strict industry standards. Understanding the characteristics and production of E6013 electrodes can significantly benefit welders in choosing the right materials for their projects, ultimately enhancing their productivity and results in various welding applications.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025