Лют . 11, 2025 10:15

Back to list

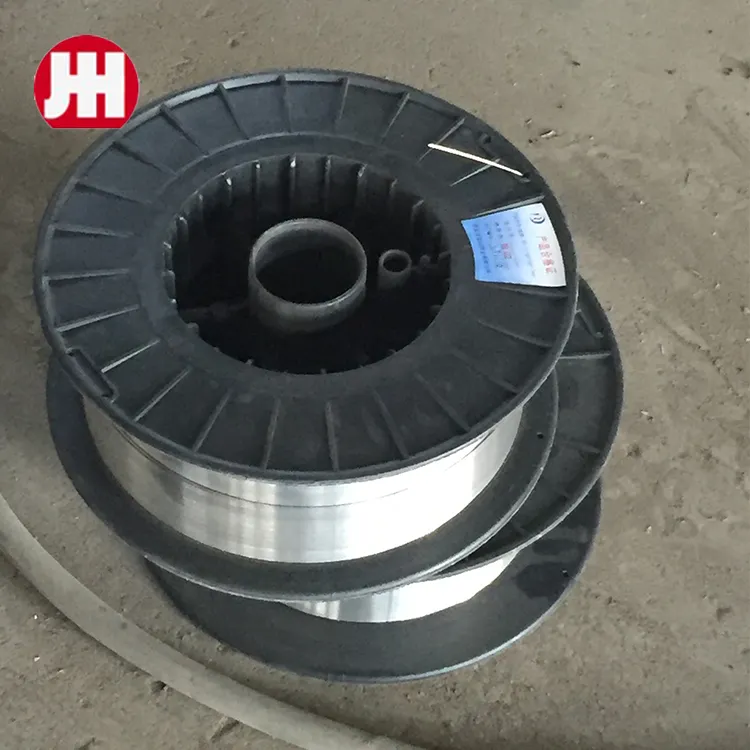

mig flux core welding wire

Success in welding projects, especially those involving MIG flux core welding wire, depends on understanding the product’s nuanced features and applications. As one of the most seasoned experts in the field, I offer a comprehensive insight into how this particular welding wire transforms projects from challenging undertakings to streamlined successes. This journey into the intricacies of MIG flux core welding wire will explore its key benefits, applications, and operational excellence, making it a go-to choice for welding professionals and amateur enthusiasts alike.

Expertise in using MIG flux core welding wire not only requires choosing the right wire but also perfecting techniques to optimize performance. Professional welders know the importance of adjusting machine settings to match the wire diameter and material thickness. Typically, a larger diameter wire supports higher current and faster travel speeds, ensuring efficient metal fusion. However, balancing this with optimal machine voltages and feed rates is crucial in producing welds with minimal spatter and ensuring a neat, high-quality finish. The authority of choosing the right MIG flux core welding wire also demands attention to detail in selecting its composition. Wire with a higher percentage of deoxidizers is essential when working with metals prone to rust or mill scale, thereby reducing porosity and ensuring a clean, robust weld. Additionally, picking a wire with the right tensile strength and elongation properties is imperative, as these dictate the weld’s ability to withstand mechanical stress without failing. A testament to the MIG flux core welding wire’s functionalities is the trust bestowed upon it by industry-standard certifications and user endorsements. Wires marketed with the AWS (American Welding Society) classification assure users of adherence to rigorous quality and performance standards, making them a trustworthy choice for critical welding applications. In summary, MIG flux core welding wire is not just a tool but a composite solution molded by expertise and engineered for excellence. Its adaptability for both challenging environments and simple setups portrays it as an embodiment of reliable, efficient welding. As one navigates through various welding needs—be it the robust demands of manufacturing giants or the precision needs of creative artisans—the structured design and professional application of MIG flux core welding wire stand unparalleled, promising not just results but a professional welding experience worth the investment.

Expertise in using MIG flux core welding wire not only requires choosing the right wire but also perfecting techniques to optimize performance. Professional welders know the importance of adjusting machine settings to match the wire diameter and material thickness. Typically, a larger diameter wire supports higher current and faster travel speeds, ensuring efficient metal fusion. However, balancing this with optimal machine voltages and feed rates is crucial in producing welds with minimal spatter and ensuring a neat, high-quality finish. The authority of choosing the right MIG flux core welding wire also demands attention to detail in selecting its composition. Wire with a higher percentage of deoxidizers is essential when working with metals prone to rust or mill scale, thereby reducing porosity and ensuring a clean, robust weld. Additionally, picking a wire with the right tensile strength and elongation properties is imperative, as these dictate the weld’s ability to withstand mechanical stress without failing. A testament to the MIG flux core welding wire’s functionalities is the trust bestowed upon it by industry-standard certifications and user endorsements. Wires marketed with the AWS (American Welding Society) classification assure users of adherence to rigorous quality and performance standards, making them a trustworthy choice for critical welding applications. In summary, MIG flux core welding wire is not just a tool but a composite solution molded by expertise and engineered for excellence. Its adaptability for both challenging environments and simple setups portrays it as an embodiment of reliable, efficient welding. As one navigates through various welding needs—be it the robust demands of manufacturing giants or the precision needs of creative artisans—the structured design and professional application of MIG flux core welding wire stand unparalleled, promising not just results but a professional welding experience worth the investment.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025