Січ . 20, 2025 05:34

Back to list

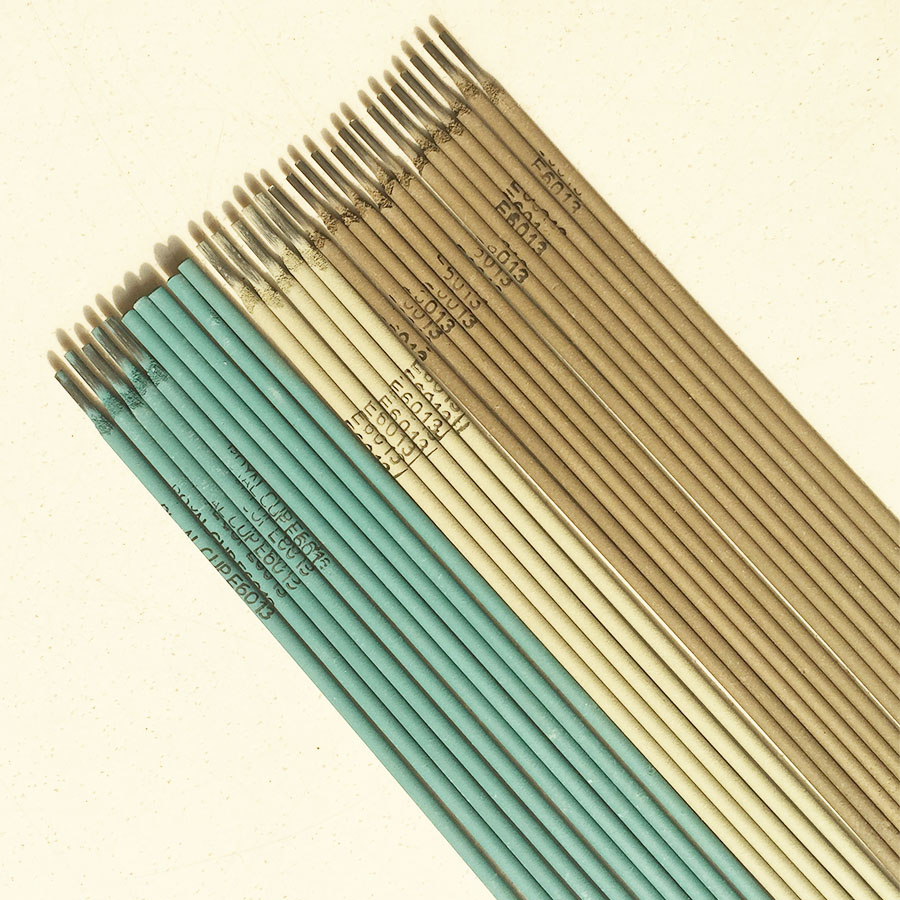

mig welding wire price

When considering the cost of MIG welding wire, several factors come into play, shaping the value and long-term benefits of various options available in the market. As a dedicated professional delving into this specific subject matter, we shall explore the aspects influencing pricing, strategic purchasing decisions, and the impact on overall project efficiency and quality.

Achieving the best value does not merely suggest acquiring the cheapest option; rather, it involves a balanced consideration of price, quality, and suitability for the intended application. Quality wires typically offer longer-lasting performance, reducing downtime from wire feed issues or defects in the welding seam, which ultimately reflects on project timelines and costs. For bulk projects, engaging directly with manufacturers or authorized distributors can lead to discounts or customized solutions that better match your welding requirements. Additionally, loyalty programs or industry partnerships might offer long-term savings and access to technical support, enhancing your operational efficiency. Evaluating Purchase from Trustworthy Sources Sourcing your MIG welding wire from reputable suppliers is fundamental in securing both cost-effectiveness and reliability in material performance. Ensure that any potential supplier has credentials, customer reviews, and a track record of delivering quality products. Authenticity certificates or compliance with industry standards can bolster your trust in their offerings. The Impact of MIG Welding Wire on Project Quality Professional welders understand that the right wire choice can drastically impact welding quality, affecting surface finish, structural integrity, and aesthetic appearance of the welds. Investing in appropriate MIG wire results in fewer occurrences of rework and rejection, saving both time and money. Moreover, specific projects might require wires with specialized coatings or alloy compositions to meet unique environmental or mechanical demands. High-quality wires also provide smoother feedability and better arc stability, reducing spatter and the need for cleanup post-welding. In summary, the price of MIG welding wire is an intersection of numerous factors, including composition, dimensions, and brand reputation. Making informed purchasing decisions requires a careful analysis of these facets, coupled with a reliable supplier network. Investing in the right wire influences overall project efficiency, elevating the quality and durability of your welds. As you make your buying decisions, prioritize wires that align well with your project goals and operational demands to ensure the best outcomes in your welding undertakings.

Achieving the best value does not merely suggest acquiring the cheapest option; rather, it involves a balanced consideration of price, quality, and suitability for the intended application. Quality wires typically offer longer-lasting performance, reducing downtime from wire feed issues or defects in the welding seam, which ultimately reflects on project timelines and costs. For bulk projects, engaging directly with manufacturers or authorized distributors can lead to discounts or customized solutions that better match your welding requirements. Additionally, loyalty programs or industry partnerships might offer long-term savings and access to technical support, enhancing your operational efficiency. Evaluating Purchase from Trustworthy Sources Sourcing your MIG welding wire from reputable suppliers is fundamental in securing both cost-effectiveness and reliability in material performance. Ensure that any potential supplier has credentials, customer reviews, and a track record of delivering quality products. Authenticity certificates or compliance with industry standards can bolster your trust in their offerings. The Impact of MIG Welding Wire on Project Quality Professional welders understand that the right wire choice can drastically impact welding quality, affecting surface finish, structural integrity, and aesthetic appearance of the welds. Investing in appropriate MIG wire results in fewer occurrences of rework and rejection, saving both time and money. Moreover, specific projects might require wires with specialized coatings or alloy compositions to meet unique environmental or mechanical demands. High-quality wires also provide smoother feedability and better arc stability, reducing spatter and the need for cleanup post-welding. In summary, the price of MIG welding wire is an intersection of numerous factors, including composition, dimensions, and brand reputation. Making informed purchasing decisions requires a careful analysis of these facets, coupled with a reliable supplier network. Investing in the right wire influences overall project efficiency, elevating the quality and durability of your welds. As you make your buying decisions, prioritize wires that align well with your project goals and operational demands to ensure the best outcomes in your welding undertakings.

Previous:

Next:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025