Січ . 20, 2025 01:49

Back to list

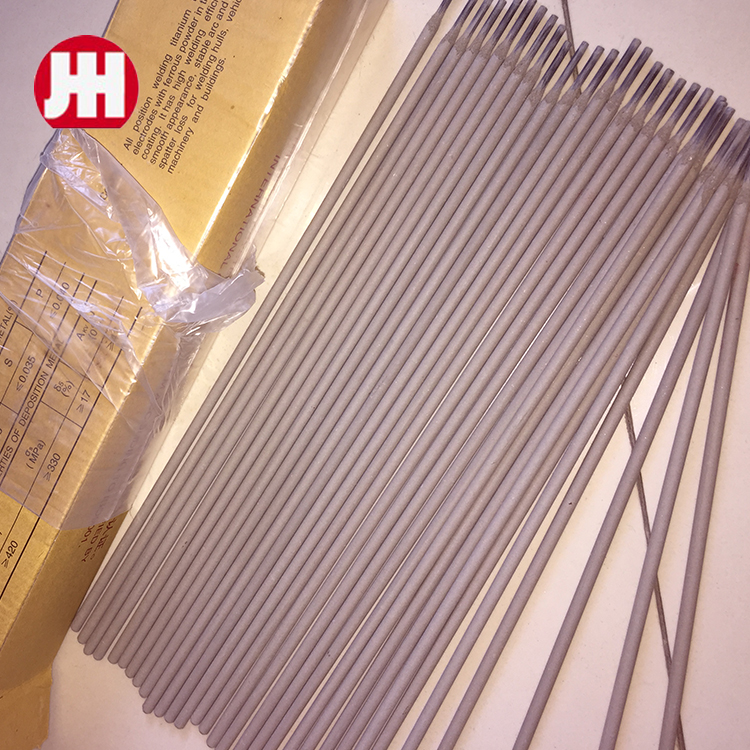

cellulose electrode e6010

The E6010 welding electrode stands as a pillar in the welding industry, recognized for its versatility and effectiveness in penetrating and fusing metals. For professionals seeking an electrode that delivers both strength and reliability, the E6010 offers a unique set of characteristics that have solidified its reputation among seasoned welders.

When it comes to expertise in welding, the capabilities of an E6010 electrode align perfectly with the demands for flexibility and strength. Its consistent performance across a range of materials and environments underscores its credibility as a reliable tool in a welder's arsenal. This reliability is particularly emphasized in industries where safety and integrity cannot be compromised. Industry veterans often regard the E6010 as an electrode that trusted results against stringent safety and quality standards. Furthermore, authoritative welding guides and resources consistently recognize E6010 electrodes. Their features are detailed in welding literature and recommended by welding authorities for educational purposes, fostering training for both budding and experienced welders. This widespread acknowledgment from reputable sources enhances the electrode’s reputation, underscoring its usefulness in various welding applications. Trustworthiness in welding is synonymous with the assurance of quality and safety, and few electrodes embody this as the E6010 does. Quality manufacturers adhere to strict standards in producing these electrodes, ensuring each batch meets defined welding specifications. As a result, welders using E6010 can rely on consistency and performance clarity, crucial factors in executing jobs that demand precision and safety. In conclusion, the E6010 electrode is more than just a tool. It is a trusted companion for welders, built on decades of proven performance and reliability in the field. Its ability to deliver strong, clean welds in challenging circumstances, coupled with accolades from industry experts, underscores its authoritative place in welding. For those in pursuit of a high-performance electrode that guarantees expertise-driven outcomes, the E6010 establishes itself not just as a choice, but as the intelligent choice for professionals.

When it comes to expertise in welding, the capabilities of an E6010 electrode align perfectly with the demands for flexibility and strength. Its consistent performance across a range of materials and environments underscores its credibility as a reliable tool in a welder's arsenal. This reliability is particularly emphasized in industries where safety and integrity cannot be compromised. Industry veterans often regard the E6010 as an electrode that trusted results against stringent safety and quality standards. Furthermore, authoritative welding guides and resources consistently recognize E6010 electrodes. Their features are detailed in welding literature and recommended by welding authorities for educational purposes, fostering training for both budding and experienced welders. This widespread acknowledgment from reputable sources enhances the electrode’s reputation, underscoring its usefulness in various welding applications. Trustworthiness in welding is synonymous with the assurance of quality and safety, and few electrodes embody this as the E6010 does. Quality manufacturers adhere to strict standards in producing these electrodes, ensuring each batch meets defined welding specifications. As a result, welders using E6010 can rely on consistency and performance clarity, crucial factors in executing jobs that demand precision and safety. In conclusion, the E6010 electrode is more than just a tool. It is a trusted companion for welders, built on decades of proven performance and reliability in the field. Its ability to deliver strong, clean welds in challenging circumstances, coupled with accolades from industry experts, underscores its authoritative place in welding. For those in pursuit of a high-performance electrode that guarantees expertise-driven outcomes, the E6010 establishes itself not just as a choice, but as the intelligent choice for professionals.

Previous:

Latest news

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025