welding rod 4043 factory

The Importance of Quality Welding Rods A Focus on 4043 Welding Rods

Welding is a fundamental process in various industries, providing the means to join metal components effectively. Among the various types of welding rods available, the 4043 welding rod stands out as a favored choice for many applications, particularly in the field of aluminum welding. Understanding the significance of quality welding rods, especially 4043 rods, can help professionals achieve superior results in their projects.

Composition and Properties of 4043 Welding Rods

The 4043 welding rod is primarily composed of aluminum-silicon alloy, making it particularly suited for welding aluminum materials. The alloy contains approximately 5% silicon, which lowers the melting point, enhances fluidity, and improves puddle stability during the welding process. This characteristic is critical when it comes to welding thin aluminum sections, as it allows for better control and reduces the likelihood of burning through the base material.

The 4043 rod exhibits excellent corrosion resistance, making it an ideal choice for applications exposed to harsh environments, such as marine and automotive industries. Moreover, the alloy’s ability to provide a smooth, aesthetically pleasing weld finish further adds to its appeal. These properties combined ensure that structures welded with 4043 rods maintain their integrity and appearance over time.

Applications of 4043 Welding Rods

4043 welding rods are widely used in various applications across different sectors. In the automotive industry, they are commonly employed to repair and fabricate aluminum components like radiators, engine parts, and chassis. The food and beverage sector also benefits from 4043 rods due to their resistance to corrosion, often using them for creating equipment that meets health and safety regulations.

welding rod 4043 factory

In the construction and repair of marine vessels, these rods are essential due to their ability to weld aluminum frames and hulls, ensuring durability against saltwater corrosion. The aerospace industry, too, utilizes 4043 rods for their lightweight yet strong welds, which are critical in minimizing the overall weight of aircraft.

Factors to Consider When Sourcing 4043 Welding Rods

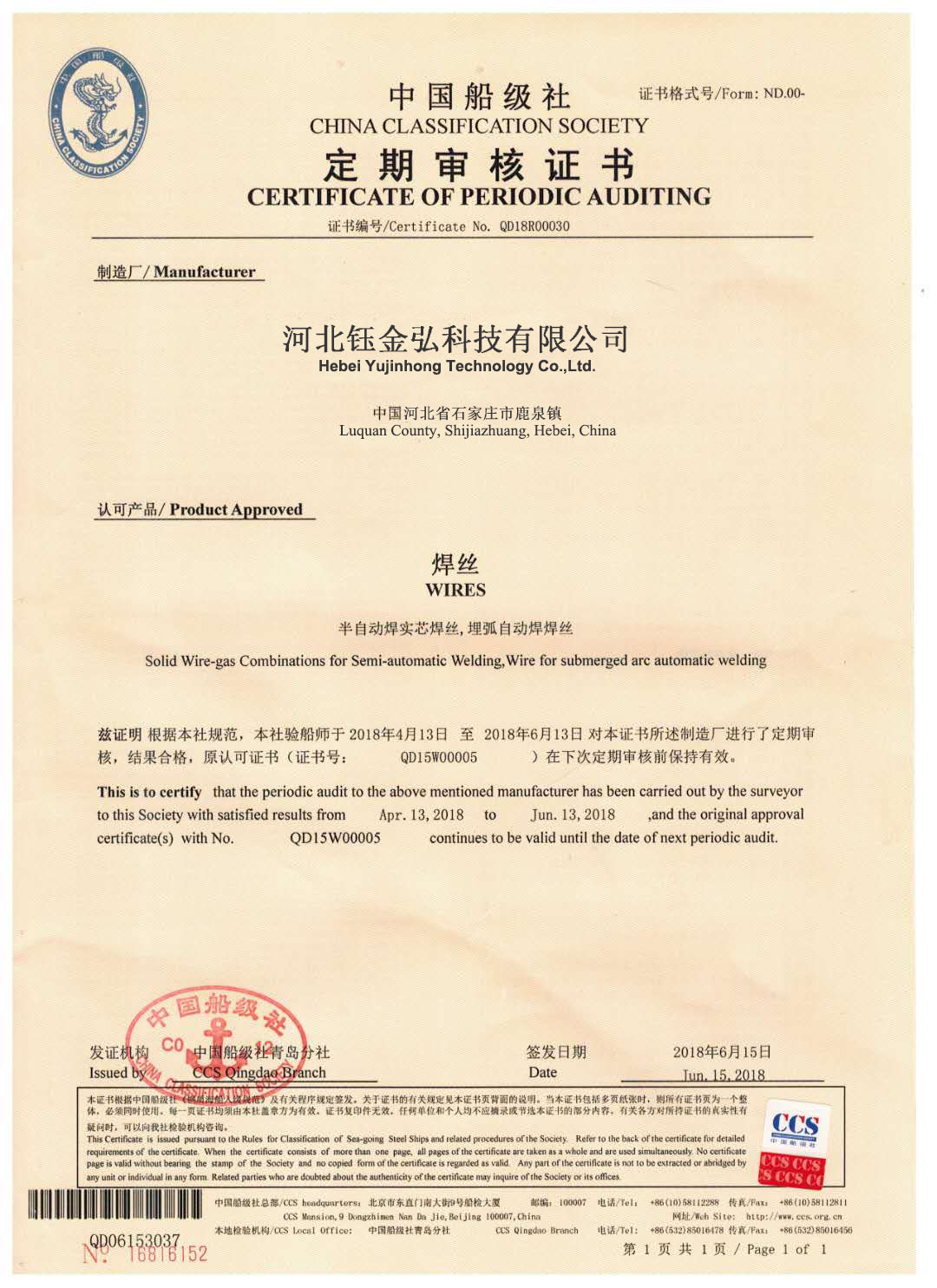

When looking to source 4043 welding rods from factories, several factors should be taken into consideration. First and foremost, it is crucial to ensure that the rods are produced to meet industry standards and specifications. This guarantees consistency in quality and performance, significantly impacting the effectiveness of the welding process.

Furthermore, sourcing from reputable manufacturers ensures that the rods undergo rigorous quality control testing. This process often includes checks for alloy composition, mechanical properties, and visual inspections to avoid defects. Eco-friendly practices during manufacturing can also be an important consideration for companies striving to minimize their environmental impact.

Conclusion

In conclusion, 4043 welding rods play an essential role in the welding of aluminum components across various industries. Their favorable properties, including excellent corrosion resistance and ease of use, make them an indispensable tool for a wide range of applications. When sourcing these rods from factories, it is vital to prioritize quality and compliance with industry standards to achieve the best possible results. By doing so, professionals in the field can ensure that their welding projects are not only successful but also durable and visually appealing. Investing in high-quality 4043 welding rods not only enhances the quality of welds but also contributes to the safety and longevity of the final product.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025