welding rod j421 supplier

Understanding the Importance of J421 Welding Rods and Their Suppliers

Welding is a critical process in various industries, including construction, automotive, and manufacturing. Among the many types of welding rods available, the J421 welding rod holds a significant place due to its unique properties and versatility. As industries continue to evolve, selecting the right welding rod and supplier has become increasingly vital for ensuring quality and reliability in welded structures.

What is J421 Welding Rod?

J421 welding rods are primarily used for shielded metal arc welding (SMAW) and are composed of an alloy that delivers excellent mechanical properties and arc stability. These rods are designed for welding low and medium-strength steels, making them suitable for a wide array of applications such as structural components, machinery, and repair work. The J421 specification refers to the Tensile strength and chemical composition of the rod, ensuring it meets stringent requirements set by industry standards.

Key Properties

The J421 welding rod is recognized for its exceptional weldability and good performance under various welding conditions. Key advantages of using J421 rods include - Versatility J421 rods can be used to weld different types of steel, making them ideal for both construction and maintenance tasks. - Heat Resistance These rods can withstand high temperatures, making them suitable for applications where thermal stability is required. - Low Spatter One of the significant challenges in welding is dealing with spatter. J421 rods minimize spatter, leading to cleaner welds and reduced post-weld cleanup.

Choosing the Right Supplier

Selecting a reliable supplier for J421 welding rods is crucial. The quality of the welding rods directly affects the effectiveness of the welding process and the integrity of the final product. Here are some considerations when choosing a supplier

welding rod j421 supplier

1. Quality Assurance Ensure that the supplier adheres to industry standards and offers products that have undergone rigorous quality testing. Look for suppliers who can provide certification for their welding rods.

2. Product Range A good supplier should offer a comprehensive range of welding products, including J421 rods of various diameters and lengths, to cater to different welding needs.

3. Customer Support Reliable suppliers understand the welding process and offer technical support. They should provide adequate guidance on the use of welding rods and address any concerns that customers may have.

4. Reputation Research the supplier’s reputation in the industry. Customer reviews and testimonials can offer valuable insights into the supplier's reliability, product quality, and customer service.

5. Pricing While cost should not be the only deciding factor, it’s essential to find a supplier that offers competitive pricing without compromising on quality.

Conclusion

In summary, J421 welding rods are an essential component in the welding industry, valued for their versatility and performance. Selecting a reputable supplier is paramount to ensuring that the welding process is efficient and yields high-quality results. By investing time in selecting the right welding rods and supplier, manufacturers and contractors can enhance their welding capabilities and ensure the durability and safety of their projects.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

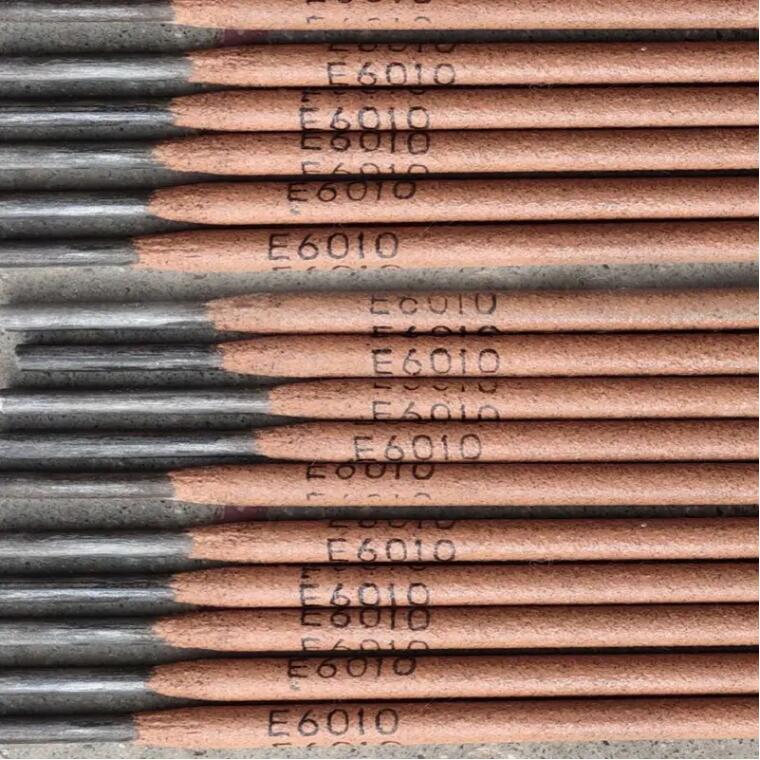

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025