Wholesale 3.2mm 7018 Welding Electrode Supplier for All Your Welding Needs

The Importance of Choosing the Right Welding Electrode A Focus on 3.2mm 7018 Electrodes

Welding is an essential process in various industries, from construction to manufacturing. It is the backbone of any structural or mechanical assembly, ensuring that different components come together with strength and durability. A critical aspect of successful welding lies in selecting the appropriate electrodes. Among the numerous options available, 3.2mm 7018 welding electrodes are particularly noteworthy, especially when sourced from a reliable wholesale supplier.

Understanding 7018 Welding Electrodes

7018 electrodes are a popular choice, notably used for mild steel and low-alloy steels. The “70” signifies a minimum tensile strength of 70,000 psi, while the “18” refers to the percentage of weld metal that consists of iron powder. This allows for improved deposition rates and greater weld puddle control. These electrodes are known for their excellent arc stability, low spatter, and ability to produce a smooth, clean finish, making them suitable for various applications, including structural welding, automotive repairs, and pressure vessel fabrication.

Advantages of Using 3.2mm Electrodes

The 3.2mm diameter makes these electrodes versatile for different welding techniques, including stick welding (SMAW). They are ideally suited for both flat and horizontal welding positions, making them a flexible option for welders at every skill level. The size allows for a good balance between penetration and control, ensuring that even novice welders can produce high-quality welds with practice.

In addition, 7018 electrodes are designed with a low-hydrogen formulation. This is crucial to prevent porosity in the weld, ensuring the integrity and strength of the final product. Given that hydrogen can lead to defects in the weld, particularly in high-strength steels, the low-hydrogen characteristics of 7018 electrodes help mitigate this risk, resulting in stronger joints that can withstand harsh environments and stress.

Choosing the Right Supplier

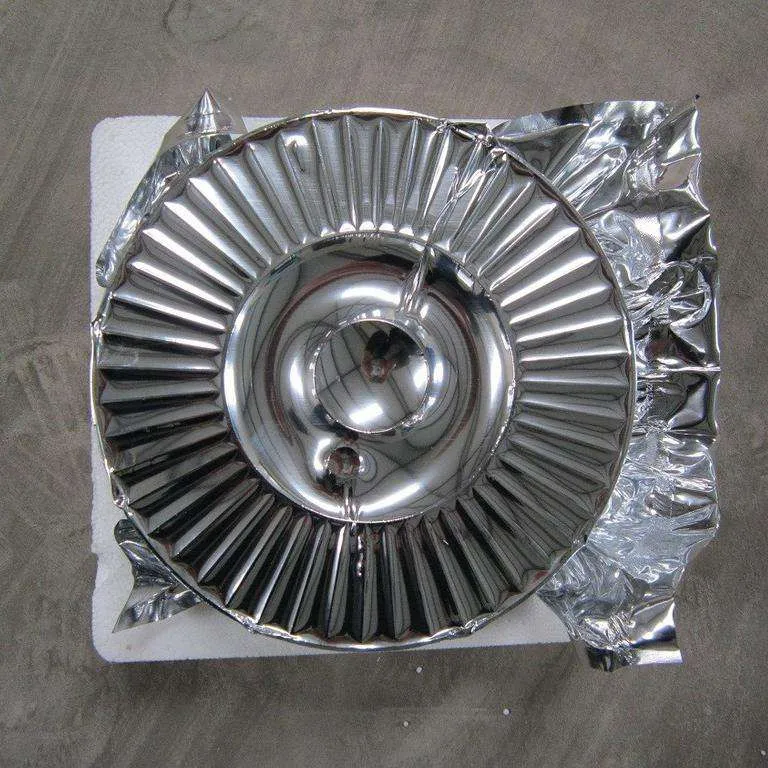

wholesale 3.2mm 7018 welding electrode supplier

When sourcing 3.2mm 7018 welding electrodes, it is imperative to select a reputable wholesale supplier. Quality varies significantly among manufacturers, and choosing a reliable source can ensure that you receive electrodes that meet industry standards.

A trusted supplier will often provide detailed product specifications, certifications, and quality assurance measures to warrant the efficacy of their electrodes. Look for suppliers who offer a variety of welding materials and provide expert advice to cater to your specific welding needs.

Cost-Effectiveness of Wholesale Purchasing

Buying welding electrodes in bulk can also offer significant cost savings. Wholesale suppliers typically provide competitive pricing, allowing businesses to reduce operational costs without compromising on quality. This is especially beneficial for projects with extensive welding requirements, where the volume of electrodes needed can add up quickly.

Supporting Sustainable Practices

Another advantage of purchasing from a reliable wholesale supplier is the potential for supporting environmentally sustainable practices. Many manufacturers are now focusing on reducing production waste and adhering to environmentally friendly processes. By choosing suppliers who prioritize sustainability, you contribute to initiatives that minimize the environmental impact of welding materials and processes.

Conclusion

In conclusion, 3.2mm 7018 welding electrodes remain a vital component in the toolbox of welders across different sectors. Their exceptional characteristics make them ideal for a variety of welding applications, ensuring strong and durable joints. However, the key to maximizing their potential lies in choosing the right supplier. A knowledgeable, trustworthy wholesale supplier can provide high-quality electrodes and support the needs of the welding community while also promoting cost savings and sustainability. Take the time to research and select a reputable supplier, and you will be well on your way to achieving successful and efficient welding outcomes.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025