Yangiliklar

-

Welding is a critical skill in many industries, but it can also pose significant dangers, particuKo'proq o'qish

Welding is a critical skill in many industries, but it can also pose significant dangers, particuKo'proq o'qish -

Setting the wrong amperage can cause weld defects and trouble starting the arc. If you’re nKo'proq o'qish

Setting the wrong amperage can cause weld defects and trouble starting the arc. If you’re nKo'proq o'qish -

There was a young welder who worked in a large manufacturing plant. Every day he was assigned difKo'proq o'qish

There was a young welder who worked in a large manufacturing plant. Every day he was assigned difKo'proq o'qish -

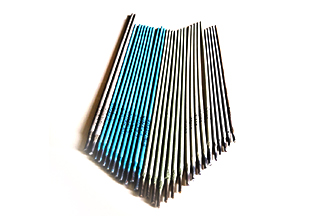

E6013 electrodes feature a flux coating composed of ferromanganese, cellulose, rutile, potassiumKo'proq o'qish

E6013 electrodes feature a flux coating composed of ferromanganese, cellulose, rutile, potassiumKo'proq o'qish -

During the welding process, the two output ends of the welding machine are in contact with the weKo'proq o'qish

During the welding process, the two output ends of the welding machine are in contact with the weKo'proq o'qish -

1. Piece As a tool, welding rods are usually produced in batches, so "pieces" are often usKo'proq o'qish

1. Piece As a tool, welding rods are usually produced in batches, so "pieces" are often usKo'proq o'qish -

I am a welder who has been doing welding for five years. I learned welding when I was in technicaKo'proq o'qish

I am a welder who has been doing welding for five years. I learned welding when I was in technicaKo'proq o'qish -

Stick welding works by using a consumable electrode coated in flux. When the electrode is hKo'proq o'qish

Stick welding works by using a consumable electrode coated in flux. When the electrode is hKo'proq o'qish -

welders nowadays will receive corresponding training before taking up their posts, but the freshnKo'proq o'qish

welders nowadays will receive corresponding training before taking up their posts, but the freshnKo'proq o'qish -

Q: What materials can you weld with stick welding? - Stick weldingKo'proq o'qish

Q: What materials can you weld with stick welding? - Stick weldingKo'proq o'qish -

I am an old welder with 40 years of welding experience. Thinking about the welding road I have waKo'proq o'qish

I am an old welder with 40 years of welding experience. Thinking about the welding road I have waKo'proq o'qish -

Welding codes and standards are critical guidelines that ensure consistency, safety, and quality in welding practices across various industries.Ko'proq o'qish

Welding codes and standards are critical guidelines that ensure consistency, safety, and quality in welding practices across various industries.Ko'proq o'qish