1/16% Manufacturing Process of Welding Rods in Modern Factories

The 1/16% E7018 Welding Rod Factory A Crucial Component of Modern Welding

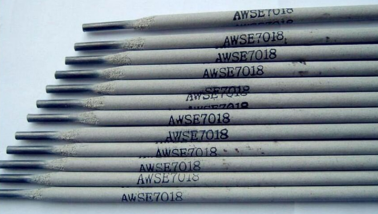

In the world of manufacturing and construction, welding is an integral process that ensures the structural integrity and durability of metal components. Among the numerous types of welding rods available, the 1/16% E7018 welding rod stands out for its unique properties and applications. The factory that produces these rods plays a critical role in various industries, ensuring that welders have access to high-quality materials. This article explores the importance of the 1/16% E7018 welding rod factory in the manufacturing ecosystem.

Understanding E7018 Welding Rods

The E7018 welding rod belongs to the shielded metal arc welding (SMAW) category, commonly referred to as stick welding. The 'E' indicates that it is an electrode; '70' refers to the minimum tensile strength of 70,000 psi; '1' designates that it is suitable for all positions; and '8' signifies the type of covering on the rod, which is primarily low hydrogen. A crucial feature of the 1/16% E7018 rods is the added alloying elements, specifically the controlled ferrite content; this ensures excellent weld properties and superb arc stability.

The 1/16% E7018 rods are particularly favored for applications involving low-alloy steels, which require high ductility, impact resistance, and low hydrogen content to minimize the risk of hydrogen-induced cracking. These rods are commonly utilized in various industries, including construction, shipbuilding, automotive, and machinery manufacturing.

The Manufacturing Process

Producing high-quality E7018 welding rods demands an intricate manufacturing process, requiring various stages and high precision. The process begins with the selection of raw materials, typically high-grade carbon steel wire and specific alloying elements. These components must meet stringent quality standards to ensure the final product's performance.

Once the raw materials are procured, the next step involves drawing the steel wire to the desired diameter, which in the case of 1/16% rods, is quite fine and requires careful handling. The wire is then coated with a flux material that serves multiple functions, including protecting the molten weld pool from atmospheric contamination and stabilizing the arc during welding.

Following coating, the rods undergo a drying process to remove any moisture, as the presence of water can lead to hydrogen embrittlement. This step is critically important in maintaining the low hydrogen characteristic of E7018 rods. Once dried, the rods are cut to length and packaged, ready for distribution to various industries.

1/16 welding rod factory

Quality Control

In the factory environment, quality control is paramount. Rigorous testing and inspection are conducted at several stages of production to ensure that the final product meets industry standards and specifications. Mechanical properties, such as tensile strength and impact resistance, are assessed through standardized testing procedures. Additionally, each batch is subjected to metallurgical analysis to confirm that the composition aligns with the required guidelines.

Quality assurance not only guarantees the performance of the welding rods but also enhances safety for welders and end-users. Defective rods can lead to severe structural failures, highlighting the necessity for uncompromised quality in the manufacturing process.

Economic Impact and Future Trends

The 1/16% E7018 welding rod factory plays a significant role in the economy by contributing to various sectors that rely on strong and durable metal fabrication. The demand for these rods often correlates with industry growth, particularly in construction and infrastructure development. As more projects emerge globally, the need for reliable welding materials continues to rise.

Looking towards the future, advancements in technology and automation are expected to reshape the welding rod manufacturing landscape. Innovations may lead to more efficient production methods, further ensuring consistency and quality in welding products. Additionally, the growing focus on sustainability might drive factories to adopt eco-friendly practices, minimizing waste and energy consumption.

Conclusion

The 1/16% E7018 welding rod factory is essential in the welding industry, providing crucial materials that ensure the strength and resilience of welded structures. With its comprehensive manufacturing process and strict quality control measures, the factory not only supports various industries but also contributes significantly to the economy. As the demand for high-quality welding rods continues to grow, the factory's role will increasingly evolve, integrating new technologies and adhering to sustainability practices for a robust future.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025