3.2mm 202.5mm Welding Electrode Production and Quality Standards Overview

The Rise of 3.2mm 202.5mm Welding Electrodes Innovations in the Welding Industry

In the world of metal fabrication and construction, welding plays a crucial role in ensuring the integrity and durability of structures. Among the various tools and materials used in this process, welding electrodes are essential. They serve as the consumable part of the welding equipment, providing both the filler material and the necessary electrical conductivity. Among the diverse options available in the market today, 3.2mm 202.5mm welding electrodes have emerged as a popular choice for many professionals in the industry. This article explores the significance of this specific size, the advancements in manufacturing techniques, and the future of welding electrodes.

Understanding Welding Electrodes

Welding electrodes are categorized based on their diameter, length, and the type of welding process they are designed for. The 3.2mm diameter is particularly favored for its versatility and ease of handling. This size allows for a balance between welding speed and the heat generated during the process, making it ideal for both thin and moderately thick materials. On the other hand, the standard length of 202.5mm provides welders with ample reach, ensuring that they can operate comfortably across various welding positions.

Benefits of 3.2mm 202.5mm Electrodes

One of the primary advantages of using 3.2mm 202.5mm welding electrodes is their ability to produce clean and strong welds. This size facilitates better arc stability and reduces the risk of excessive spatter, which is often a concern with larger electrodes. Additionally, these electrodes are compatible with a wide range of materials, including carbon steel, stainless steel, and low-alloy steel. This adaptability makes them highly sought after in sectors such as construction, automotive, and heavy machinery manufacturing.

Moreover, the use of 3.2mm electrodes allows for greater control during the welding process. Welders can manipulate the electrode more easily, leading to improved precision and accuracy in their work. This is particularly important in projects where aesthetics and structural integrity are crucial.

Innovations in Manufacturing

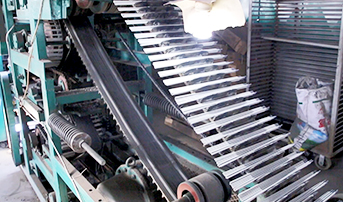

3.2mm 2.5mm welding electrode factory

The manufacturing of welding electrodes has seen significant advancements in recent years. Improvements in raw materials, coating technologies, and production processes have resulted in electrodes that not only perform better but are also more environmentally friendly. Modern factories employ automated systems that ensure consistent quality and reduce waste during production.

One innovative approach includes the development of composite coatings that enhance the overall performance of the electrodes. These coatings are designed to provide better shielding gas coverage, which protects the weld pool from atmospheric contaminants. As a result, the welds produced are cleaner and stronger, minimizing the need for post-weld cleaning processes.

Sustainability in Welding Electrode Production

As the welding industry continues to evolve, sustainability has become a priority. Many manufacturers of 3.2mm 202.5mm welding electrodes are now exploring ways to reduce their carbon footprint. This includes using recyclable materials in the production process and implementing energy-efficient manufacturing practices. Furthermore, there is a growing trend toward developing eco-friendly electrodes that utilize less harmful substances in their coating formulations.

The Future of Welding Electrodes

Looking ahead, the demand for 3.2mm 202.5mm welding electrodes is expected to grow. As industries increasingly rely on automated welding processes and robotics, the need for high-quality, reliable electrodes will continue to rise. Manufacturers must stay ahead of technological advancements to meet the evolving demands of their customers.

In conclusion, 3.2mm 202.5mm welding electrodes are poised to be a cornerstone in the welding industry for years to come. Their balanced size, coupled with advancements in manufacturing and a focus on sustainability, makes them an excellent option for professionals across various sectors. As we move forward, continued innovation and a commitment to quality will be essential in maintaining the relevance and effectiveness of welding electrodes in an ever-changing industrial landscape.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025