Manufacturers of China 316L Stainless Steel Electrodes for Effective Welding Solutions

An Overview of China 316L Electrode Manufacturers

China has emerged as a global leader in the manufacturing of a wide array of industrial products, including welding electrodes. Among these, the 316L electrode is notable for its superior properties, particularly in environments requiring high resistance to corrosion and heat. This article explores the landscape of China 316L electrode manufacturers, highlighting their processes, product quality, and the significant role they play in various industries.

Understanding 316L Electrode

The 316L stainless steel electrode is an alloy that contains low carbon content (hence the L in its name), which enhances its weldability and decreases the risk of sensitization during welding. This type of electrode is widely utilized in industries such as oil and gas, chemical processing, marine applications, and in the construction of food processing equipment. The unparalleled corrosion resistance and durability of 316L make it the preferred choice for applications that involve exposure to harsh chemicals and extreme temperatures.

The Manufacturing Landscape

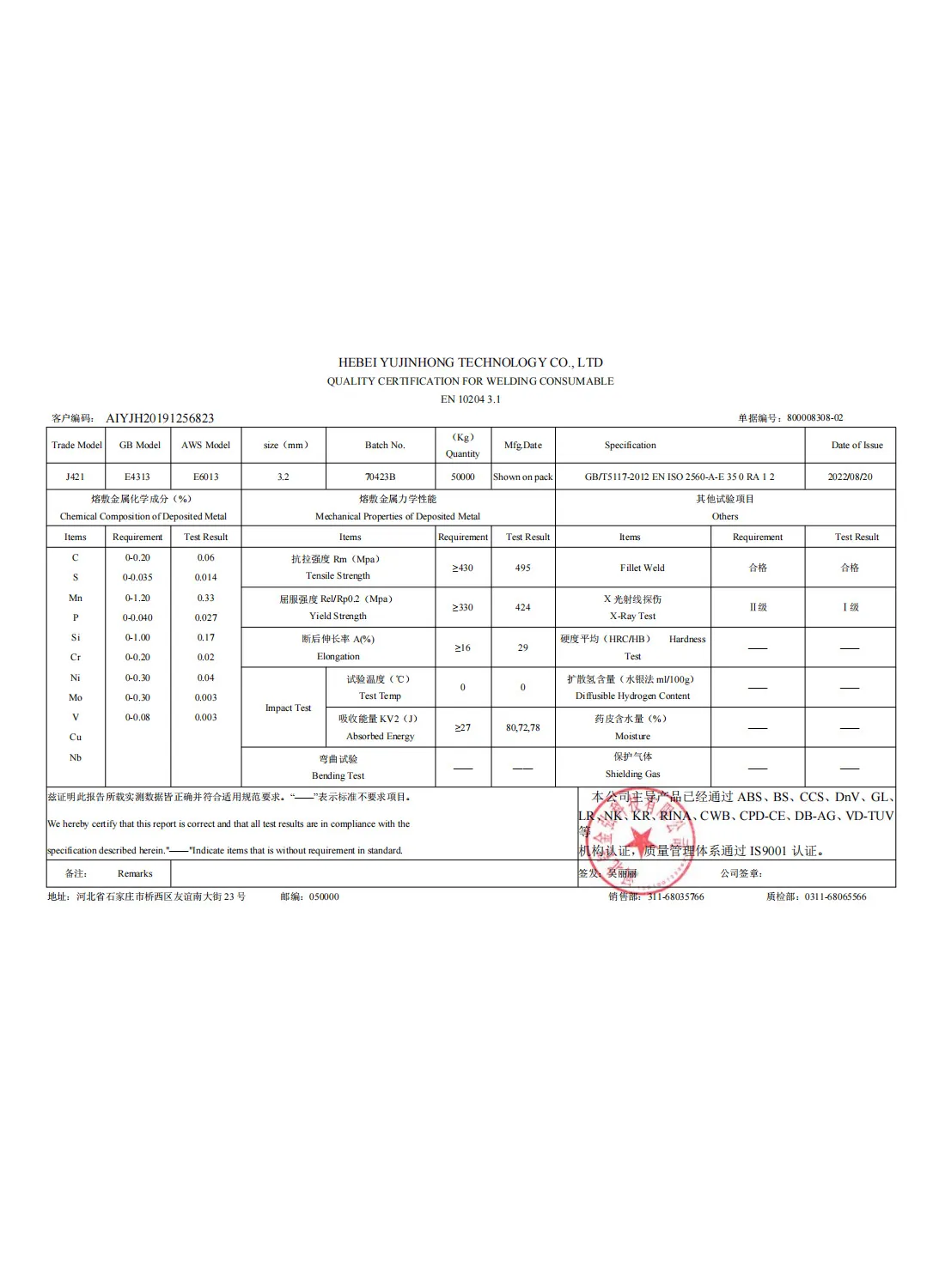

China is home to numerous manufacturers specializing in the production of 316L electrodes. These manufacturers leverage advanced technologies and processes to ensure high-quality output. Most of them adhere to international standards such as ISO 90012015, which guarantees quality management systems that monitor all stages of production, from raw material procurement to the final product inspection.

The manufacturing process typically involves several stages, including the mixing of raw materials, which usually consists of nickel, molybdenum, and chromium. Following this, the mixture is subjected to various heating processes and then shaped into electrodes using state-of-the-art machinery. This attention to detail in the manufacturing process helps ensure that each electrode maintains the properties expected of 316L steel.

Quality Control

Quality assurance is a critical aspect of 316L electrode manufacturing. Reputable manufacturers conduct extensive testing and quality control procedures throughout the production process. Tests may include mechanical property assessments, corrosion resistance evaluations, and metallographic examination to ensure that the electrodes meet specific standards required for various applications. This rigorous approach not only guarantees product integrity but also builds trust with clients globally.

china 316l electrodo manufacturers

Competitive Advantage

One of the key advantages of Chinese 316L electrode manufacturers is cost efficiency. The availability of abundant raw materials, coupled with relatively lower labor costs, allows these manufacturers to produce high-quality electrodes at competitive prices. Additionally, many firms invest in research and development to continually innovate and improve their products, ensuring they meet the evolving needs of the market.

Furthermore, many manufacturers in China have expanded their reach by establishing partnerships and distribution networks worldwide. This global presence enables them to cater to an international clientele, thereby enhancing the reputation of Chinese manufacturers in the global market.

Challenges and Opportunities

While the market for 316L electrodes is thriving, manufacturers face certain challenges, including fluctuating raw material prices and stringent international trade regulations. However, these obstacles also present opportunities for manufacturers to improve their operational efficiencies and establish more sustainable practices.

Moreover, the growing demand for eco-friendly and durable construction materials presents an opportunity for Chinese manufacturers to innovate and expand their product lines. By focusing on sustainable manufacturing processes, they can appeal to environmentally conscious consumers and businesses.

Conclusion

In conclusion, China's 316L electrode manufacturers play a vital role in meeting the demands of various industries that require high-quality, durable, and corrosion-resistant welding electrodes. With their adherence to international quality standards, cost-effectiveness, and commitment to innovation, these manufacturers are poised to remain competitive in the global market. As sectors continue to evolve and new challenges arise, the adaptability and resourcefulness of China's manufacturing industry will be key to shaping the future of welding technologies.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025