china electrode for welding mig manufacturer

The Landscape of MIG Welding Electrode Manufacturers in China

In recent years, China has solidified its position as one of the leading manufacturers of welding electrodes, particularly for Metal Inert Gas (MIG) welding. This welding process, known for its versatility, speed, and efficiency, has made it a preferred choice in various industrial sectors, including automotive, shipbuilding, and construction. As demand continues to rise globally, Chinese manufacturers have stepped up to meet these needs, offering a range of products that cater to both domestic and international markets.

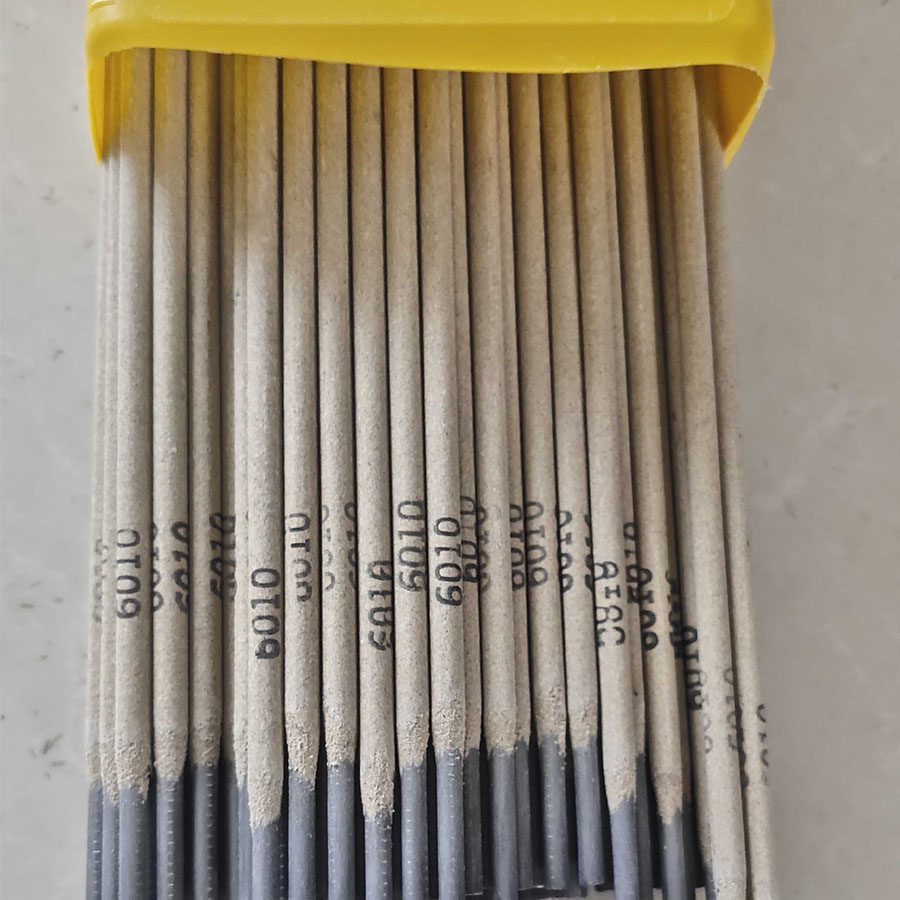

MIG welding electrodes play a crucial role in the welding process, as they supply the filler material and help maintain the electric arc between the welding torch and the workpiece. The quality of the electrodes directly impacts the strength and durability of the weld seam. Chinese manufacturers have invested significantly in research and development to enhance the quality and performance of their MIG welding electrodes. Many companies are combining advanced technologies with traditional manufacturing techniques to produce electrodes that meet international standards.

The Landscape of MIG Welding Electrode Manufacturers in China

Moreover, China's vast industrial landscape and robust supply chain capabilities allow for efficient production and distribution. Manufacturers are strategically located in industrial hubs, which facilitates quick delivery and reduces lead times. This efficiency is essential for industries that require immediate access to welding supplies to meet production demands.

china electrode for welding mig manufacturer

In addition to standard MIG welding electrodes, Chinese manufacturers also provide customized solutions tailored to specific customer requirements. They employ experienced engineers and technicians who can develop specialized electrodes for unique applications, ensuring that clients get the best possible product for their welding needs. This commitment to customization has helped many manufacturers establish long-term relationships with clients across various sectors.

Quality assurance is a top priority among reputable Chinese MIG welding electrode manufacturers. Many of these companies adhere to international quality management standards, such as ISO 9001, and undergo regular inspections and audits. This dedication to quality ensures that the electrodes produced are reliable and effective, giving customers confidence in their welding processes.

Furthermore, as environmental regulations become more stringent globally, many Chinese manufacturers are also focusing on sustainable practices. This includes the adoption of eco-friendly materials and processes that minimize waste and reduce emissions. Such initiatives not only align with global trends but also cater to the growing demand for sustainable manufacturing practices in the welding industry.

In conclusion, the landscape of MIG welding electrode manufacturing in China is marked by innovation, competitiveness, and a commitment to quality. With a focus on both meeting global demands and adhering to sustainability practices, Chinese manufacturers are well-positioned to play a vital role in the future of the welding industry. As businesses continue to seek reliable and cost-effective solutions, the partnership between manufacturers and consumers will undoubtedly grow, paving the way for advancements in welding technology and methodologies.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025