China Stainless Steel Stick Welding Manufacturing Facilities and Processes

The Rise of Stick Welding Stainless Steel in China An Overview of Factories and Advancements

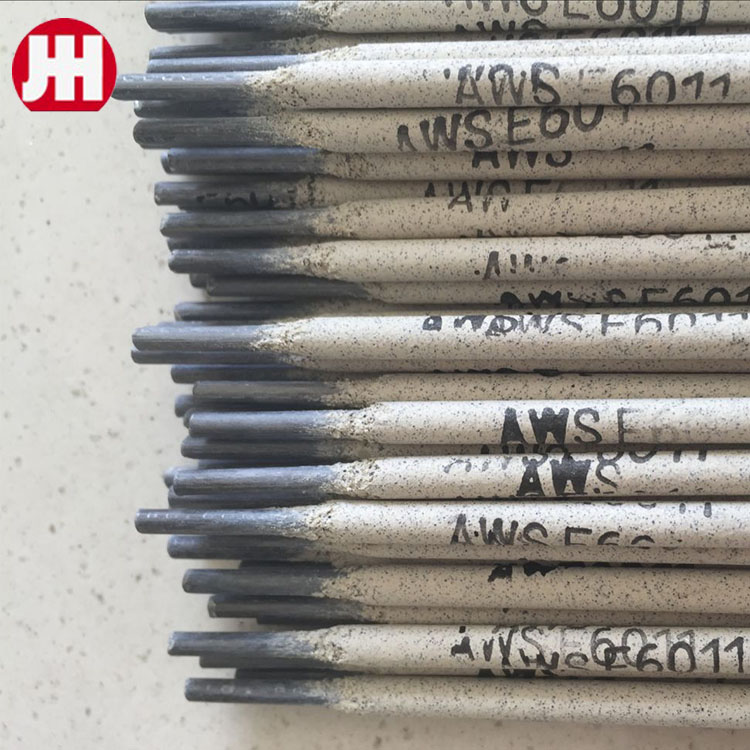

In recent years, China has emerged as a global leader in manufacturing, with stick welding of stainless steel becoming a crucial aspect of the country’s industrial prowess. Stick welding, or shielded metal arc welding (SMAW), is a versatile and widely used welding process characterized by its simplicity and effectiveness. It has proven to be especially beneficial for stainless steel applications due to its ability to penetrate deep into the material, allowing for strong and durable welds.

China's stick welding factories are increasingly adopting advanced technologies and methodologies that enhance the quality and efficiency of their welding processes. These factories are equipped with state-of-the-art machinery that utilizes digital controls, automated systems, and robotics. The incorporation of automation in stick welding has significantly improved productivity while reducing the chance of error. This technological shift has positioned Chinese factories as front-runners in the global welding market, consistently meeting high standards and demanding specifications.

The Rise of Stick Welding Stainless Steel in China An Overview of Factories and Advancements

Additionally, the environmental considerations of stick welding processes are being addressed in Chinese factories. With rising global concerns about sustainability, many manufacturers are investing in eco-friendly practices. This includes using welding consumables that minimize harmful emissions and implementing systems that recycle waste materials. By adopting such comprehensive approaches, Chinese manufacturers are keenly aware of their corporate responsibilities while ensuring that they maintain competitive pricing and high-quality outputs.

china stick welding stainless factories

Moreover, the growing demand for stainless steel in construction, automotive, and aerospace industries has led to an increase in the production capacities of these factories. As industries ramp up their operations, the versatility of stick welding allows manufacturers to cater to a variety of applications, ranging from heavy machinery to intricate components used in aerospace engineering. This adaptability has made stick welding a preferred choice among several sectors, further entrenching its significance in China’s manufacturing landscape.

The competitive edge enjoyed by Chinese stick welding factories is also a result of their ability to rapidly scale production. With the adoption of lean manufacturing principles, factories are streamlining operations, reducing waste, and improving workflow. This efficiency not only meets the rising demands of both domestic and international markets but also allows for quick turnaround times, which is increasingly critical in a fast-paced global economy.

Another notable trend is the growth of export markets for Chinese stainless steel products. With a robust supply chain and affordable pricing, many Chinese factories are now exporting their products worldwide. By embracing quality standards such as ISO certifications, these factories are enhancing their credibility and reliability in the global market, making them a preferred supplier for various industries across the globe.

In conclusion, Chinese stick welding factories are at the forefront of modern manufacturing, especially in the processing of stainless steel. By embracing advanced technologies, investing in workforce training, and adopting sustainable practices, these factories are set to lead the global welding market. As the industry evolves, China is likely to continue its ascent as a dominant player, ensuring that stick welding remains an essential technique in achieving high-quality products that meet the rigorous demands of various sectors. This dynamic shift not only highlights the country’s capabilities but also showcases the future of manufacturing and welding, with an emphasis on innovation, efficiency, and sustainability.

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025

-

Simple Welding Rods – High Quality Arc & Aluminium Welding Rods Wholesale Reliable Stick Welding Rods ManufacturersNewsJul.05,2025

-

3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High QualityNewsJul.04,2025

-

Stainless Steel Welding Rods for Sale – High Quality 7018 Welding Rods SupplierNewsJul.04,2025

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025