copper coated welded wire

The Advantages and Applications of Copper Coated Welded Wire

Copper coated welded wire is increasingly becoming a popular material in various industries due to its unique properties and advantages. This type of wire is made by welding steel wires together and then coating them with copper. The resulting product combines the strength and durability of steel with the excellent conductivity and corrosion resistance of copper. This article will explore the benefits, applications, and considerations of using copper coated welded wire.

Benefits of Copper Coated Welded Wire

1. Enhanced Conductivity One of the primary advantages of copper coated welded wire is its enhanced electrical conductivity. The copper coating allows for better performance in electrical applications compared to plain steel wire. This makes it an ideal choice for various electrical and telecommunications applications where efficient conductivity is essential.

2. Corrosion Resistance Steel, if left uncoated, is prone to rust and corrosion when exposed to moisture and other environmental factors. However, the copper coating provides an excellent barrier against corrosion. This feature extends the lifespan of the wire, making it suitable for outdoor applications and harsher environments where traditional steel wire would fail.

3. Strength and Durability The inherent strength of the steel core ensures that the wire can handle heavy loads and extreme conditions. This combination of strength with the protective and conductive properties of copper makes it a versatile choice across different industries.

4. Cost Efficiency Although the initial cost of copper coated welded wire might be higher than that of plain wire, its durability and longevity often result in lower maintenance and replacement costs. This makes it a cost-effective solution in the long run, especially for large-scale industrial applications.

5. Versatility Copper coated welded wire can be manufactured in various sizes and configurations, making it suitable for a wide range of applications. From construction and fencing to electrical wiring and mesh products, its versatility is one of its strongest selling points.

Applications of Copper Coated Welded Wire

copper coated welded wire

1. Electrical Applications Given its excellent conductivity, copper coated welded wire is commonly used in electrical wiring systems. It is often utilized in the manufacturing of power cables, connectors, and other components where efficient electrical performance is crucial.

2. Construction Sector In the construction industry, copper coated welded wire is employed for reinforcing concrete slabs, walls, and structures. Its robust nature ensures structural integrity, while the copper coating minimizes the risk of corrosion over time.

3. Fencing Copper coated welded wire is a popular choice for fencing applications, particularly in agricultural settings. Its resistance to rust makes it ideal for enclosures that must withstand exposure to the elements, protecting livestock and crops.

4. Telecommunication Systems The telecommunications industry benefits from the conductivity of copper coated welded wire, where it is used in the development of transmission lines and support structures that require effective electrical performance.

5. Crafts and DIY Projects On a smaller scale, copper coated welded wire is also favored by artisans and DIY enthusiasts for creating decorative items, sculptures, and other projects where both strength and aesthetic appeal are desired.

Conclusion

Copper coated welded wire represents a significant advancement in materials technology with its unique blend of properties. The benefits of enhanced conductivity, corrosion resistance, and high strength make it an appealing choice across numerous applications. From large-scale industrial uses in construction and telecommunications to everyday crafting projects, this wire offers versatile solutions that meet varied needs.

When selecting copper coated welded wire for a project, it is essential to consider factors such as wire diameter, coating thickness, and specific application requirements. Understanding these elements ensures optimal performance and extends the lifespan of the product. As industries continue to innovate, the use of copper coated welded wire is likely to expand, solidifying its role as a vital material in modern engineering and construction. Investing in quality copper coated welded wire can lead to substantial long-term benefits, making it a wise choice for both professional and DIY endeavors.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

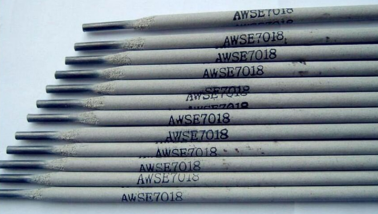

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025