Yan . 14, 2025 15:51

Back to list

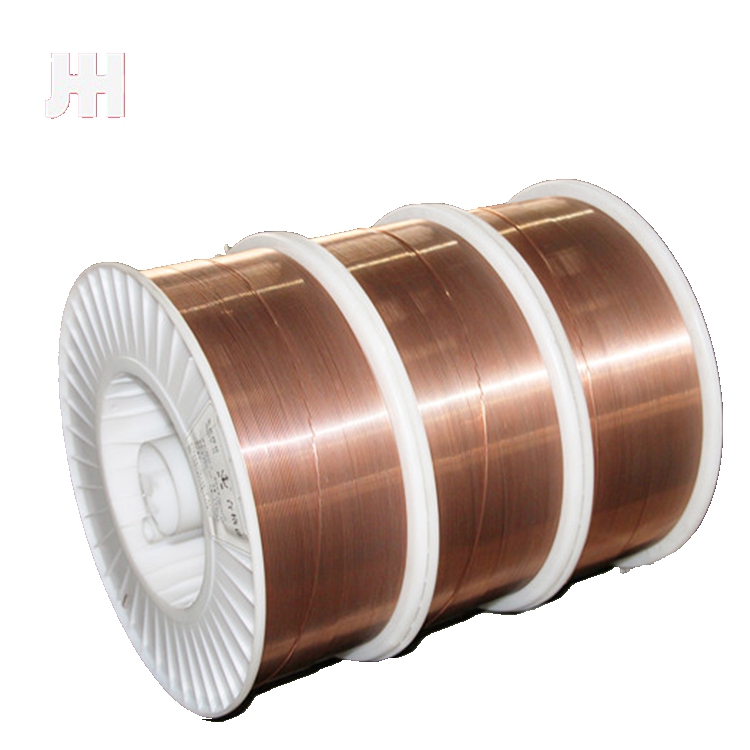

Arc Welding Consumable Submerged Welding Wire

The 6010 electrode is a core element in the welding industry, renowned for its exceptional versatility and performance across various applications. This high-cellulose sodium electrode is predominantly used for pipeline welding and other demanding tasks requiring deep penetration.

In terms of authoritativeness, the 6010 is backed by extensive endorsements within the welding community. It holds a respected position due to its compatibility with both AC and DC welding machines, ensuring wide applicability. Its preference for use with DCEN (Direct Current Electrode Negative) further highlights its specialized role in the field, providing deep penetration while maintaining control over the welding puddle. Trustworthiness associated with the 6010 electrode stems from its consistent performance over years of practical use. Renowned brands that manufacture these electrodes are known for upholding stringent quality standards, ensuring their products meet and exceed industry expectations. Users can depend on these electrodes for long-lasting welds that withstand the test of time, crucial for industries where reliability is paramount. In conclusion, the 6010 electrode is a cornerstone of the welding industry, offering unmatched stability, penetration, and adaptability. Its effectiveness in challenging conditions and a variety of positions makes it a versatile choice for professional welders. For those willing to invest time in understanding its nuances, the 6010 proves to be a trustworthy and authoritative tool in their arsenal. Embracing this electrode not only enhances the quality of one's work but also speaks to a welder's proficiency and dedication to their craft.

In terms of authoritativeness, the 6010 is backed by extensive endorsements within the welding community. It holds a respected position due to its compatibility with both AC and DC welding machines, ensuring wide applicability. Its preference for use with DCEN (Direct Current Electrode Negative) further highlights its specialized role in the field, providing deep penetration while maintaining control over the welding puddle. Trustworthiness associated with the 6010 electrode stems from its consistent performance over years of practical use. Renowned brands that manufacture these electrodes are known for upholding stringent quality standards, ensuring their products meet and exceed industry expectations. Users can depend on these electrodes for long-lasting welds that withstand the test of time, crucial for industries where reliability is paramount. In conclusion, the 6010 electrode is a cornerstone of the welding industry, offering unmatched stability, penetration, and adaptability. Its effectiveness in challenging conditions and a variety of positions makes it a versatile choice for professional welders. For those willing to invest time in understanding its nuances, the 6010 proves to be a trustworthy and authoritative tool in their arsenal. Embracing this electrode not only enhances the quality of one's work but also speaks to a welder's proficiency and dedication to their craft.

Latest news

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025