soldador electrodos

The topic of welding electrodes, or soldador electrodos in Spanish, is a crucial aspect of the welding process, influencing both the quality of the weld and the overall efficiency of the operation. Understanding the different types of electrodes available, their compositions, and suitable applications can greatly enhance the capabilities of welders in various industries.

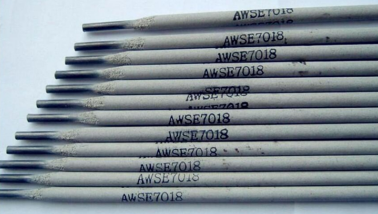

Welding electrodes come in two primary types consumable and non-consumable. Consumable electrodes melt during the welding process, providing filler material to the weld pool. Common examples include the E6010 and E7018 electrodes, which are popular among professional welders for their stable arcs and excellent penetration qualities. These electrodes are primarily used for steel welding, and their choice often depends on the specific project requirements, such as the type of steel and the position of the weld.

The topic of welding electrodes, or soldador electrodos in Spanish, is a crucial aspect of the welding process, influencing both the quality of the weld and the overall efficiency of the operation

. Understanding the different types of electrodes available, their compositions, and suitable applications can greatly enhance the capabilities of welders in various industries.The coating on electrodes also plays a significant role in the welding process. Different coatings are designed to stabilize the arc, improve the weld appearance, and protect the molten weld pool from atmospheric contamination. For instance, electrodes with a cellulose coating are advantageous for vertical and overhead welding, while those with iron powder can enhance deposition rates.

soldador electrodos

Choosing the right electrode encompasses more than just the material; it includes understanding the specifications of the welding machine, the thickness of the materials, and the desired weld characteristics. Each project may require different parameters, including voltage, amperage, and travel speed, all of which can be influenced by the selected electrode.

Moreover, the storage and handling of welding electrodes are paramount. Moisture can adversely affect the performance of the electrodes, leading to issues like porosity and poor arc stability. Thus, it is essential to store them in a dry environment and follow manufacturers' recommendations for baking and preheating prior to use.

In conclusion, comprehending the various aspects of welding electrodes is fundamental for achieving successful welds in various applications. Whether one is a novice or a seasoned professional, investing time in learning about the specifications, types, and proper use of electrodes can lead to significant improvements in the quality of work and overall productivity in welding operations.

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025