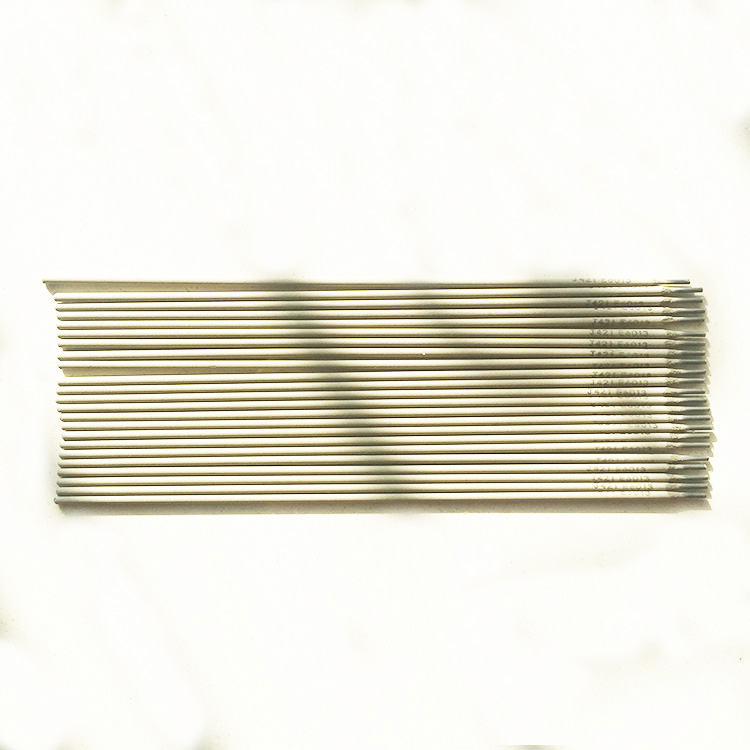

stick welding stainless factory

The Significance of Stick Welding in Stainless Steel Manufacturing

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a widely utilized welding process in various industries, including the manufacturing of stainless steel products. This method, although one of the oldest forms of welding, remains relevant today, particularly in factories where stainless steel components are fabricated for diverse applications.

What is Stick Welding?

Stick welding involves the use of a consumable electrode coated in flux. During the welding process, an electric current is passed through the electrode, creating an arc between the electrode and the workpiece. The heat generated melts both the electrode and the base metal, forming a molten pool which, upon cooling, solidifies to create a strong bond.

This type of welding is characterized by its simplicity and versatility, making it suitable for various environments, from construction sites to manufacturing factories. In the case of stainless steel, stick welding is advantageous due to its ability to be used in varied positions and its effectiveness in outdoor settings, where wind and other environmental factors might affect other welding processes.

Advantages of Stick Welding in Stainless Steel Fabrication

1. Cost-Effectiveness Stick welding equipment is typically less expensive than other welding alternatives, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. This affordability makes stick welding an attractive option for factories looking to optimize their production costs.

2. Versatility Stick welding can be employed on a variety of stainless steel grades, making it an adaptable choice for manufacturers dealing with different types of stainless steel. Whether it's austenitic, ferritic, or duplex stainless steel, stick welding can effectively bond these materials.

stick welding stainless factory

3. Excellent Penetration The nature of stick welding allows for deeper penetration into the base metal, which is particularly important when welding thicker sections of stainless steel. This factor enhances the strength of the weld joint, allowing it to withstand high pressures and stresses.

4. Simplicity and Ease of Use The stick welding process is relatively easy to learn and execute. This is particularly beneficial for factories aiming to train new welders quickly. With proper training, workers can become proficient in stick welding in a short period.

5. Minimal Equipment Requirements Stick welding requires fewer equipment and machine settings, resulting in less downtime during production. The straightforward setup allows factories to maintain high levels of efficiency.

Challenges of Stick Welding in Stainless Steel

While stick welding has distinct advantages, it is not without its challenges. One significant issue is spatter, which can result in the need for additional cleanup. Additionally, maintaining consistent arc length and controlling the cooling rate are crucial to achieving high-quality welds. Welders must also be vigilant about the presence of contaminants on the stainless steel surface, as impurities can affect the integrity of the weld.

Conclusion

Stick welding remains a fundamental process in the factory setting, especially for the manufacturing of stainless steel components. Its cost-effectiveness, versatility, and strong weld characteristics make it an enduring choice for fabricators and manufacturers. Despite some challenges, with adequate training and attention to detail, factories can harness the benefits of stick welding to produce high-quality stainless steel products that meet industry standards.

Manufacturers continuously adapt to changing technologies and methods, but the importance of skilled stick welders and the relevance of this process in stainless steel fabrication cannot be understated. As long as there is a demand for durable, high-strength stainless steel products, stick welding will maintain a vital role in the manufacturing landscape, ensuring that industries can rely on robust materials to fulfill their needs.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025