Vertical Stick Welding 7018 Techniques and Manufacturer Insights for Optimal Results

Understanding Vertical Stick Welding (SMAW) with the 7018 Electrode

Vertical stick welding, also known as Shielded Metal Arc Welding (SMAW), is a widely used welding technique that employs consumable electrodes coated with flux to create a high-temperature electric arc between the electrode and the workpiece. Among various electrodes available, the E7018 is particularly popular due to its versatility, ease of use, and strong weld quality, making it a preferred choice for many manufacturing applications.

What is E7018?

The 7018 designation refers to a specific type of welding electrode classified under the American Welding Society (AWS) standards. The number 70 indicates that the electrode can produce a minimum tensile strength of 70,000 psi. The 1 signifies that this electrode can be used in all positions, and the 8 denotes the type of coating, which is intended for use in lower hydrogen applications.

The E7018 electrode is known for its low hydrogen content, which minimizes the risk of cracking in the weld metal, especially when working with thicker materials. This characteristic makes it especially suitable for critical applications in structural steel fabrication, pressure vessels, and heavy machinery assembly, where weld integrity is paramount.

Vertical Position Welding

Welding in the vertical position poses unique challenges that require skilled techniques and the right equipment

. Vertical stick welding with E7018 electrodes is particularly effective as it allows welders to make high-quality welds even on vertical surfaces. The electrodes can be manipulated to control the bead profile while minimizing the risk of slag build-up or uneven welds.To achieve a strong vertical weld, welders often employ a weaving technique or a series of small, controlled movements. The E7018 electrode’s design allows for smoother arc stability and better penetration, making it easier for welders to deposit metal accurately without excessive buildup of slag.

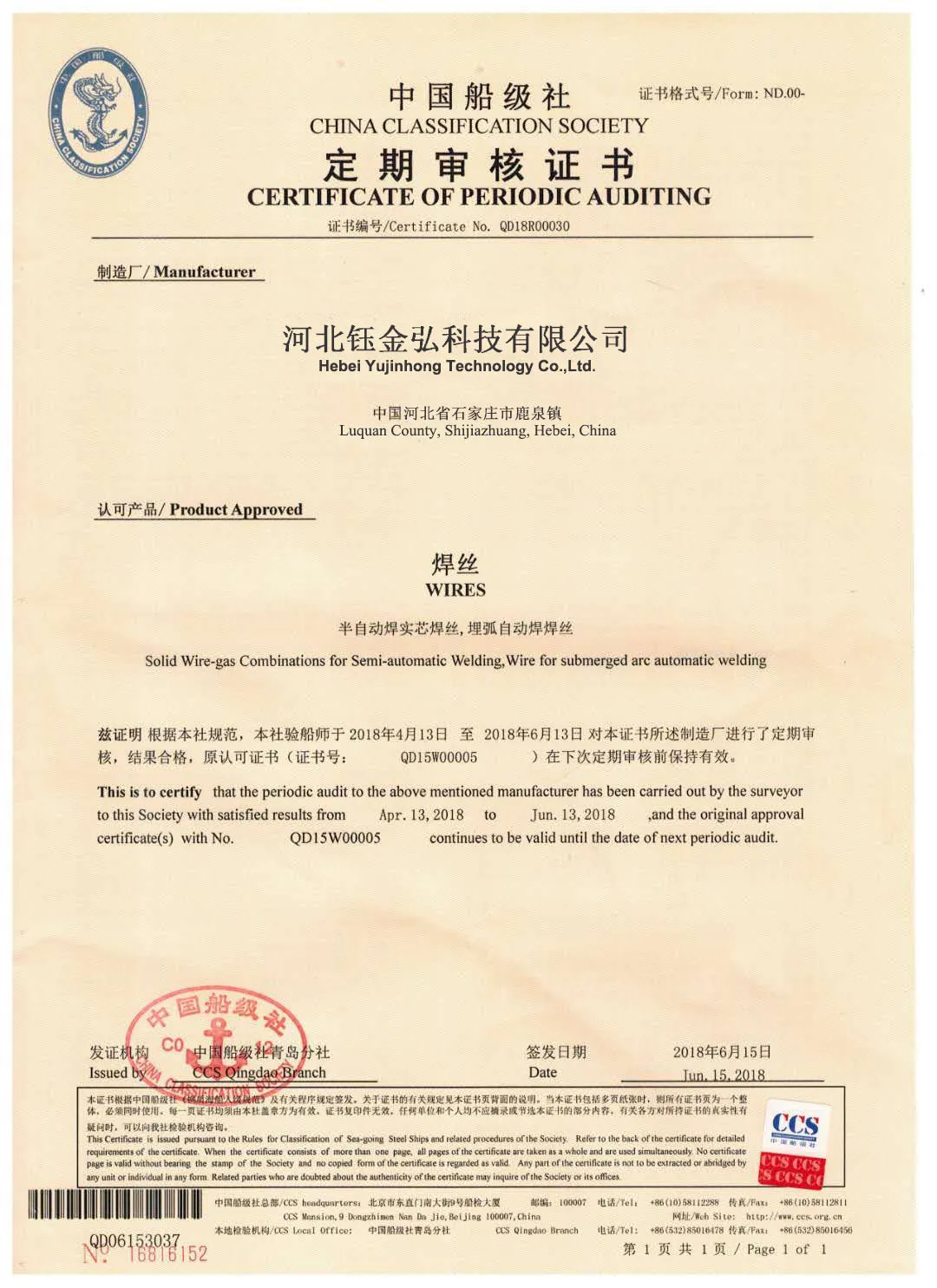

vertical stick welding 7018 manufacturer

Equipment and Preparation

Before starting vertical stick welding with E7018 electrodes, proper preparation of the workpieces is crucial. This includes cleaning the metal surfaces to remove rust, paint, or contaminants that could compromise the weld quality. Additionally, ensuring the right electrode size is important—commonly, 1/8 inch (3.2 mm) or 3/16 inch (4.8 mm) electrodes are used for most applications.

The welding equipment also plays a crucial role. A DC welder is often preferred for E7018 electrodes, set to the appropriate voltage and amperage based on the electrode size and material thickness. Proper setup helps achieve optimal arc stability and desired penetration.

Advantages of Vertical Stick Welding with E7018

1. Strong Welds E7018 electrodes provide excellent tensile strength and impact resistance, making them suitable for high-stress applications. 2. Versatility These electrodes can be used on various materials, including carbon steels, low-alloy steels, and high-strength steels, in different welding positions (flat, horizontal, vertical, and overhead). 3. Low Hydrogen Content The low hydrogen content significantly reduces the risk of cracking, allowing welds to maintain integrity even under harsh conditions or in critical applications. 4. Wide Availability E7018 electrodes are readily available from numerous manufacturers, making it easy to source the material needed for different projects.

Conclusion

Vertical stick welding with E7018 electrodes is a reliable and effective method for creating strong, high-quality welds in various applications. Whether used in construction, manufacturing, or repair work, the E7018 electrode remains a staple in the welding industry. By mastering vertical welding techniques and understanding the properties of the E7018 electrode, welders can enhance their skill set, ensuring they produce durable structures that meet strict safety and quality standards. This combination of technique, material, and equipment makes vertical stick welding a valuable asset in the skilled trades, highlighting the importance of training and experience in achieving professional welding results.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025