1/8 7018 welding rod factory

The Importance of Welding Rods A Focus on the 1/8 7018 Welding Rod Factory

In the realm of metalworking and fabrication, welding plays a crucial role in assembling strong and enduring structures. One of the most essential components of welding is the welding rod, which is pivotal for creating strong bonds between metals. Among the many types of welding rods available in the market, the 1/8 7018 welding rod stands out due to its remarkable properties and versatility. This article delves into the significance of the 1/8 7018 welding rod factory and the benefits it brings to the welding industry.

Understanding the 1/8 7018 Welding Rod

The 1/8 7018 welding rod is specifically designed for use in various welding applications, including construction, automotive, and manufacturing industries. The designation 207018 indicates the type of materials used in the rod, making it particularly suitable for welding carbon steel, low alloy steel, and certain grades of stainless steel. The percentage 1/8 refers to the diameter of the rod, which is 1/8 inch, making it an ideal choice for both thin and thick materials.

This type of welding rod is known for its excellent arc stability, low spatter, and smooth bead appearance. These characteristics make it a preferred choice among welders, as it significantly enhances productivity and the overall quality of the welds. One of the key advantages of the 1/8 7018 welding rod is its ability to withstand high levels of stress and strain, making it a reliable option for critical applications in various industries.

The Role of the Welding Rod Factory

The manufacturing process of the 1/8 7018 welding rod involves several steps, each crucial to ensuring the quality and performance of the final product. The welding rod factory is responsible for sourcing high-grade raw materials, which are then processed and formulated to create welding rods that meet industry standards.

1/8 7018 welding rod factory

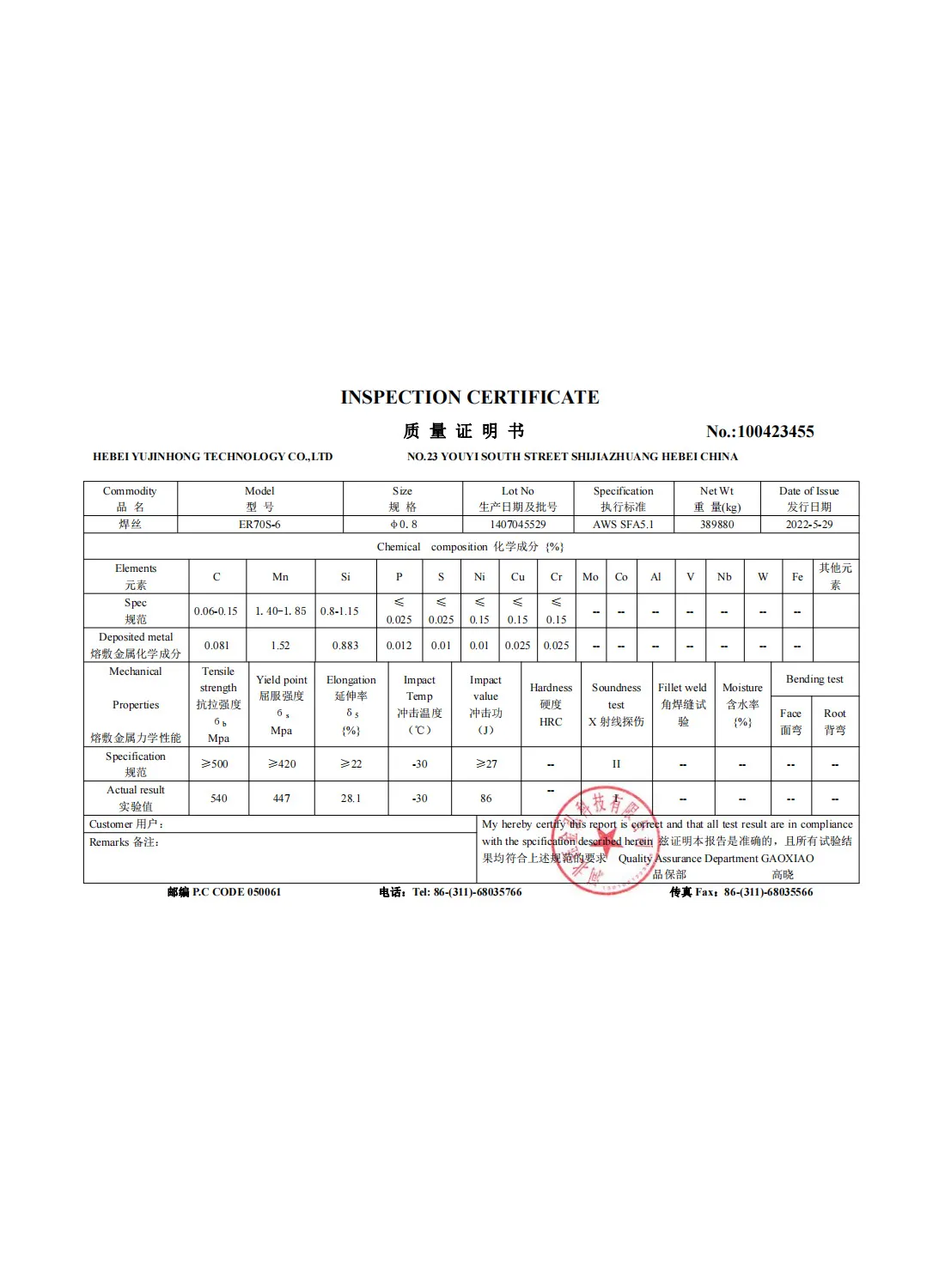

Quality control is a vital part of the production process. Factories implement rigorous testing procedures to ensure that each batch meets strict specifications regarding tensile strength, ductility, and weldability. By adhering to these standards, the factory ensures that the welding rods produced not only meet customer expectations but also comply with regulatory requirements.

Moreover, the factory invests in modern technology and skilled labor, which are essential for maintaining a competitive edge in the market. Automation and precision engineering play a significant role in optimizing production efficiency and minimizing waste. As a result, customers benefit from high-quality welding rods that are both dependable and cost-effective.

Impact on the Welding Industry

The availability of quality welding rods, such as the 1/8 7018, has a direct positive impact on the welding industry. These rods contribute to improving the quality and reliability of welds, which is crucial for safety and durability in construction projects and machinery fabrication. Moreover, the consistent performance of these rods allows welders to complete their tasks more efficiently, saving both time and resources.

Additionally, as industries strive to adopt more sustainable practices, the manufacturing processes employed in factories producing welding rods are evolving. By prioritizing environmentally friendly practices and reducing waste, these factories contribute to a greener future in industrial manufacturing.

Conclusion

The 1/8 7018 welding rod factory plays an essential role in the welding industry by producing high-quality welding rods that enhance the efficiency and reliability of welding applications. With a focus on quality control, modern technology, and sustainable practices, these factories not only meet the needs of the market but also contribute positively to the overall progress of the industry. As the demand for durable and high-performance welding materials continues to grow, the significance of reliable manufacturing sources like the 1/8 7018 welding rod factory cannot be overstated.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025