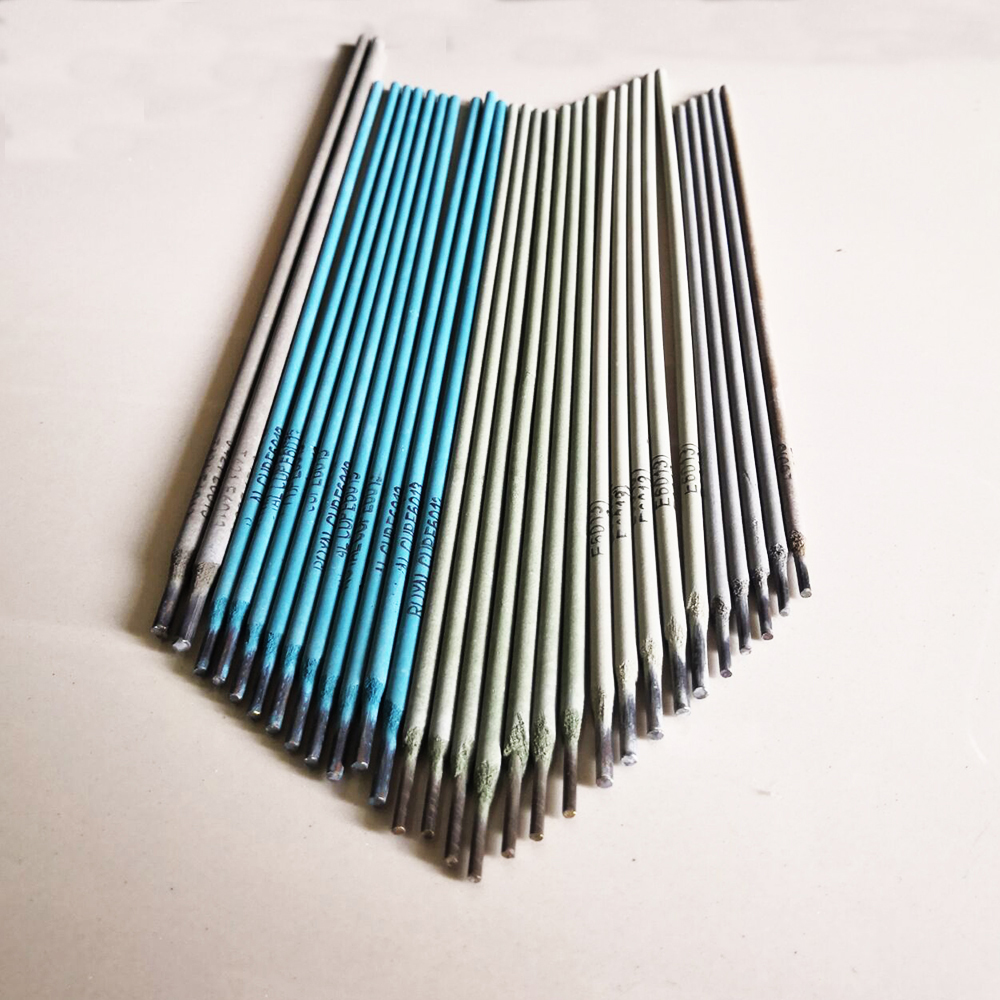

High-Quality Welding Wire Production Facilities for Every Industry Need

The Importance of 2% 200% Welding Wire in Modern Manufacturing

In the realm of modern manufacturing and construction, welding is a critical process that ensures the structural integrity and longevity of products. Among the various types of welding materials available, 2% 200% welding wire has emerged as a preferred choice for many industries due to its unique properties and advantages.

What is 2% 200% Welding Wire?

The term 2% 200% welding wire typically refers to a specific composition of filler material used in welding applications. The 2% signifies the alloying elements, which enhance the wire’s performance during the welding process. The 200% indicates the wire's ability to withstand high levels of stress and heat, making it suitable for heavy-duty applications. This combination of properties allows for strong, durable welds that can resist various environmental conditions.

Applications of 2% 200% Welding Wire

Manufacturers in various sectors have adopted 2% 200% welding wire due to its versatility. It is commonly used in industries such as automotive, aerospace, shipbuilding, and construction. In the automotive industry, for example, the wire is used to join critical components that must withstand both mechanical stresses and temperature variations. In shipbuilding, where corrosion and fatigue are significant concerns, this welding wire ensures that structures remain intact over long periods.

2 0 welding wire factory

Advantages of Using 2% 200% Welding Wire

One of the most critical advantages of 2% 200% welding wire is its excellent tensile strength. This ensures that welded joints can bear heavy loads without failing. Additionally, the wire's alloying elements improve its corrosion resistance, making it ideal for use in harsh environments, such as marine applications or chemical plants. Another noteworthy advantage is its ease of use — the wire produces minimal spatter during welding, leading to cleaner welds and less post-weld cleanup.

Quality Assurance in Manufacturing

Choosing a reputable factory for sourcing 2% 200% welding wire is vital. Quality control measures are essential to ensure that the wire meets industry standards and specifications. Factories often conduct rigorous testing, including tensile strength tests and corrosion resistance assessments, to guarantee that the welding wire performs reliably in all applications.

Conclusion

In summary, 2% 200% welding wire is a vital component in modern manufacturing, offering strong, reliable, and durable welds suitable for various industries. Its unique properties and advantages make it a preferred choice for engineers and manufacturers committed to safety and quality. As industries continue to evolve, the demand for high-performance welding materials like 2% 200% welding wire will undoubtedly grow, reinforcing its importance in the manufacturing landscape.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025