7018 Welding Electrode Manufacturing Facility Overview and Production Insights

The Importance of 7018 Welding Electrode Factories in Modern Industries

In the world of welding, the 7018 welding electrode has gained a reputation for being one of the most reliable and widely used electrodes in various industries. Known for its excellent mechanical properties and versatility, the 7018 electrode has become a staple in structural fabrication, shipbuilding, and pressure vessel manufacturing. Beyond its popularity in the welding community, the factories that produce these electrodes play a crucial role in ensuring that high-quality products are available to meet the demands of modern engineering and construction projects.

Understanding the 7018 Electrode

The 7018 electrode is a low-hydrogen, iron powder electrode that is primarily used for arc welding. The designation '7018' indicates that it can weld materials with a minimum yield strength of 70,000 psi, and it has a tensile strength of around 80,000 psi. The '1' in the designation signifies that it can be used in all positions, including flat, horizontal, vertical, and overhead. The '8' indicates that it has a low hydrogen content, which is essential for preventing the formation of cracks in the weld metal.

These unique properties make the 7018 electrode ideal for welding thicker materials, especially when strength and flexibility are paramount. Industries such as construction and manufacturing rely heavily on the performance of this electrode to ensure structural integrity and durability.

The Role of 7018 Electrode Factories

The factories that manufacture 7018 welding electrodes play an integral role in modern welding processes. These facilities are equipped with advanced technology and machinery that enable the production of high-quality electrodes that comply with stringent industry standards. A significant aspect of these factories is their commitment to quality control. Each batch of electrodes undergoes rigorous testing to ensure it meets the specified mechanical properties and consistency required for flawless welding.

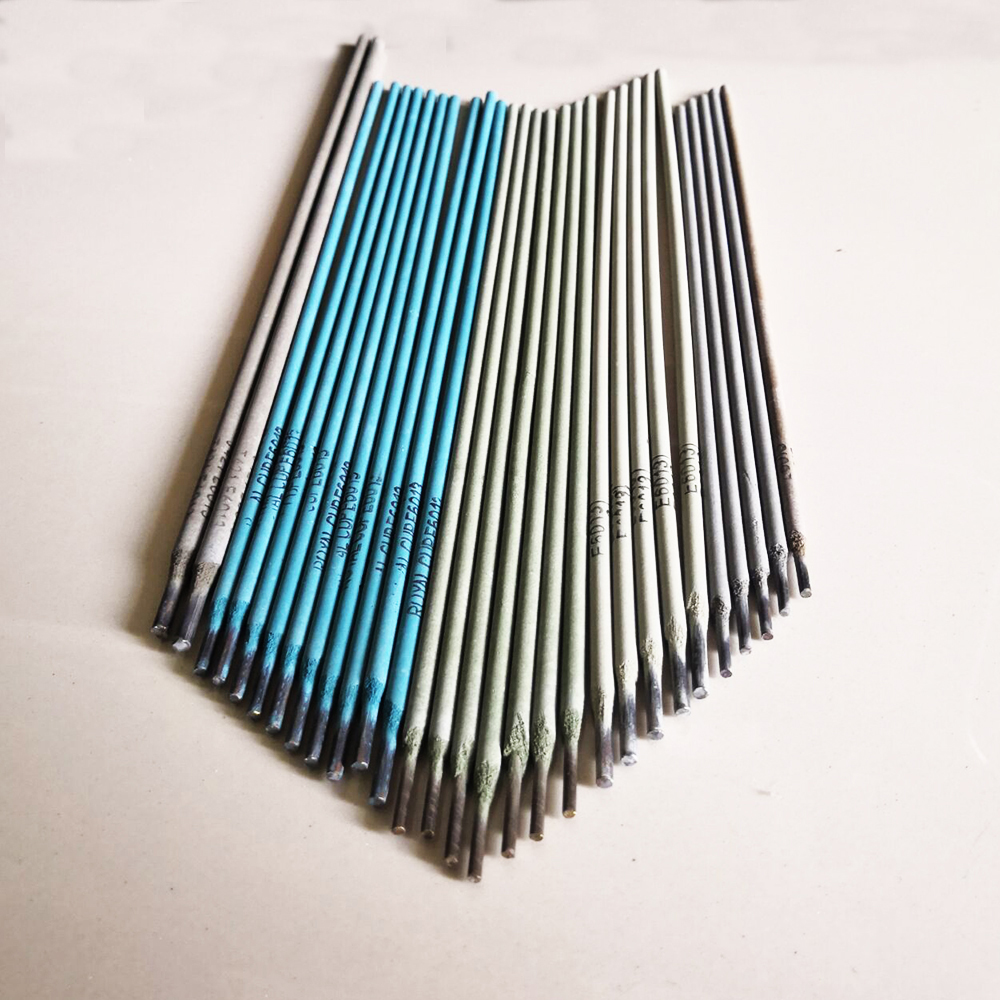

7018 welding electrode factory

Manufacturers must source high-grade raw materials, such as iron powder, slag, and alloying agents, to produce the 7018 electrodes. The chemical composition of these materials directly affects the performance of the electrode during welding. Thus, reputable factories maintain strong relationships with suppliers to ensure the quality of the raw materials they use.

Moreover, 7018 electrode factories invest in research and development to innovate and improve their products. They explore new formulations and production techniques that enhance performance characteristics, making them more suitable for specific applications. This ongoing innovation allows factories to meet the evolving needs of various industries and to remain competitive in a global marketplace.

Environmental Considerations

As industries worldwide strive for sustainability, welding electrode factories are also adapting their practices. Many are implementing environmentally friendly manufacturing processes and waste reduction strategies. Recycled materials are increasingly being utilized, and emissions are monitored to adhere to environmental regulations. Such initiatives not only contribute to a greener production process but also enhance the brand's reputation in the market.

Conclusion

In summary, the 7018 welding electrode is a vital component in numerous industries, and the factories that produce these electrodes are key to sustaining its quality and supply. Through meticulous manufacturing processes, commitment to quality control, and continuous innovation, these factories ensure that welders have access to reliable and high-performance products. As industries continue to evolve, the importance of 7018 welding electrode factories will only grow, supporting the global economy and contributing to the advancement of engineering and construction.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025