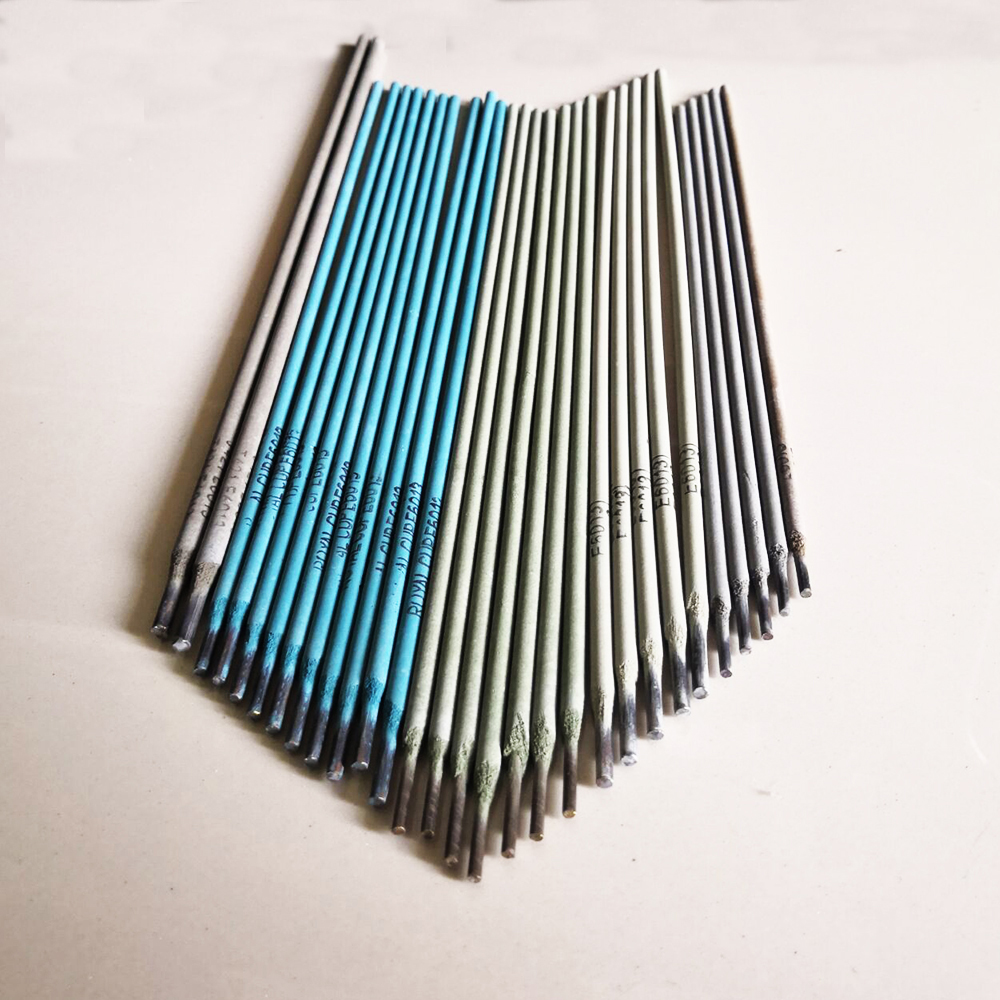

7018 electrodo para soldar manufacturer

Understanding the 7018 Electrode Manufacturer Insights

The 7018 electrode is a cornerstone in the field of welding, popular among professionals and hobbyists alike for its reliability and performance. This high-quality low hydrogen electrode is specifically designed for shielded metal arc welding (SMAW) and is often used for joining ferrous metals. The designation 7018 reveals important information about its properties the first two digits indicate the minimum tensile strength (70,000 psi), the third digit (1) signifies the position of welding, and the last digit (8) indicates the type of coating which provides a low hydrogen content.

The Importance of Choosing the Right Manufacturer

When selecting a 7018 electrode, the manufacturer plays a crucial role in determining the quality and performance of the product. The right manufacturer ensures that the electrode meets industry standards, adheres to regulations, and employs best practices in production. Each manufacturer may have its unique formulation, coating type, and manufacturing processes, which can affect the overall welding performance.

Key Characteristics of the 7018 Electrode

One of the primary characteristics that make the 7018 electrode so desirable is its low hydrogen content. Low hydrogen electrodes reduce the risk of hydrogen-induced cracking in the weld, making it particularly suitable for high-strength steels and critical applications such as pressure vessels, bridges, and structural components.

Moreover, 7018 electrodes are versatile, suitable for both AC and DC currents, which adds to their usability in different welding scenarios

. They can be used in various positions, including flat, horizontal, vertical, and overhead, allowing welders to tackle a range of projects with confidence.Performance Factors to Consider

7018 electrodo para soldar manufacturer

When assessing a manufacturer of 7018 electrodes, several performance factors should be taken into account. These include arc stability, ease of use, slag removal, and the quality of the bead finish. A well-manufactured 7018 electrode will provide a smooth arc, minimal spatter, and easy slag removal, which are crucial for achieving solid welds.

Employing modern technologies and rigorous quality control measures can greatly enhance the performance characteristics of these electrodes. Manufacturers that invest in research and development often produce superior products that can withstand the rigorous demands of industrial applications.

Environmental and Safety Standards

In today’s environmentally conscious climate, the manufacturing processes used to produce 7018 electrodes have become increasingly important. Many manufacturers now focus on sustainable practices to minimize environmental impacts, such as reducing emissions and utilizing recyclable materials.

Additionally, the safety of the welding process is paramount. High-quality manufacturers comply with safety standards and regulations to ensure that their products are safe for users. This includes proper packaging to protect the electrodes from moisture and contamination, which is crucial for maintaining their low hydrogen properties.

Conclusion

In conclusion, choosing the right manufacturer for 7018 electrodes is essential for any welding project. The quality of the electrode directly influences the welding results, affecting factors such as strength, appearance, and durability of the weld. As the demand for quality welding solutions continues to grow, manufacturers must uphold high standards of production, environmental responsibility, and safety. By understanding the characteristics of the 7018 electrode and the significance of the manufacturer, welders can make informed decisions that contribute to the success of their work.

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025