Best Welding Rods for Cast Iron - Top Manufacturers & Recommendations

When it comes to welding cast iron, choosing the right welding rod is crucial for ensuring strong and durable joints. Cast iron has unique properties that make it challenging to weld, including its brittleness and tendency to crack if not handled properly. Therefore, manufacturers and welders must select the best welding rod to achieve optimal results.

One of the top choices for welding cast iron is the nickel-based welding rod. Nickel rods, such as the ENiFe-CI and ENi3, are specifically designed for cast iron repair and provide excellent strength and ductility. They are particularly useful for welding gray iron, ductile iron, and malleable iron. The nickel content in these rods helps to improve the weld pool's fluidity and reduces the risk of cracking as the weld cools.

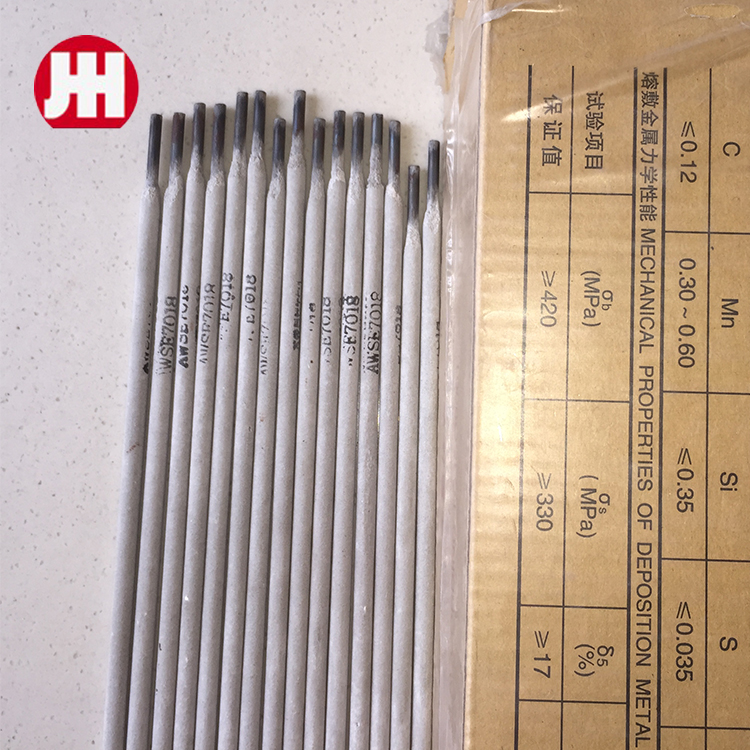

Another excellent option is the stainless steel welding rod, which is often used for joining cast iron to stainless steel. Stainless steel rods provide corrosion resistance, making them ideal for applications where exposure to moisture or chemicals is a concern. Welders commonly use AWS classifications like 309 and 312 for this purpose. However, it's essential to note that the welds produced with stainless steel can be more rigid, so proper preheating and post-weld treatment are essential to avoid cracking.

best welding rod for cast iron manufacturers

For those working with thinner sections of cast iron, specialty rods like the Cast Iron Repair Rod are available. These rods are designed for high-strength repairs and can be used to fix cracks in cast iron parts without the need for extensive preparation. They melt at a lower temperature and can fuse with the base metal effectively while minimizing the heat-affected zone.

It's also worth mentioning that proper preparation and preheating are critical when welding cast iron. Preheating the base metal to around 400°F can help reduce thermal shock and the likelihood of cracks. Additionally, welders should be mindful of their techniques. Using a short arc length and avoiding excessive heat input can significantly improve the quality of the weld.

Lastly, every manufacturer has unique welding needs, so it's crucial to test different rods to find the best one for your specific application. High-quality welding rods from reputable manufacturers will also ensure consistent performance. In conclusion, selecting the right welding rod for cast iron is essential for creating strong, lasting joints. Nickel-based rods, stainless steel rods, and specialty repair rods each offer distinct advantages, and the appropriate choice can make all the difference in successful welds.

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025