China 7016 Welding Rod Specifications and Applications for Metal Fabrication

Exploring the China 7016 Welding Rod Characteristics and Applications

Welding is an essential technique used extensively in various industries for joining materials, primarily metals. Among the numerous welding rods available in the market, the China 7016 welding rod has gained significant recognition for its unique properties and applications. In this article, we will delve into the characteristics, advantages, and applications of this particular welding rod, providing a comprehensive understanding for both professionals and enthusiasts in the field of welding.

Exploring the China 7016 Welding Rod Characteristics and Applications

One of the most significant advantages of the China 7016 welding rod is its versatility. It is suitable for various welding positions, including flat, horizontal, vertical, and overhead, providing welders with the flexibility to tackle diverse projects. Additionally, this rod exhibits excellent arc stability and minimal spatter, which contributes to cleaner welds and reduces post-weld cleanup time—a crucial factor for productivity in industrial settings.

china 7016 welding rod

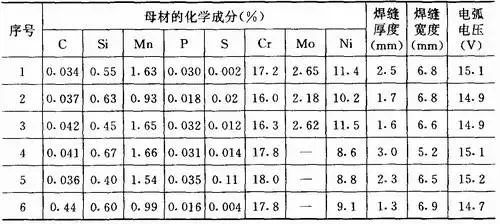

The chemical composition of the China 7016 welding rod plays a vital role in its performance. Generally, it contains a mix of iron powder, flux materials, and other elements that enhance its welding characteristics. The low hydrogen content minimizes the risk of defects and ensures that welds maintain their integrity under high stress. This makes the rod particularly valuable in industries where safety and structural reliability are paramount, such as construction, automotive, and shipbuilding.

In terms of mechanical properties, the welded joints produced with the China 7016 welding rod often exhibit high tensile strength and impact toughness. This means that once the welding is completed, the joined materials can withstand significant forces without failure—a critical aspect in load-bearing applications. The rod's ability to perform well in high-temperature environments further increases its applicability in industries that deal with heavy machinery and infrastructure.

The China 7016 welding rod is also designed to be user-friendly, making it suitable for both novice and experienced welders. Even with varying skill levels, the rod allows for good arc control and minimal distortion, which is essential for maintaining the shape and integrity of the welded components. Furthermore, it can be used effectively on both new and old steels, providing welders with the versatility needed to address different project requirements.

In conclusion, the China 7016 welding rod stands out as a reliable choice for professionals and hobbyists alike. Its exceptional properties, including low hydrogen content, high strength, and versatility in various welding positions, make it an essential tool in several industries. Whether utilized in intricate automotive repairs or large-scale construction projects, this rod ensures high-quality welds that meet safety and performance standards. As the demand for skilled welding continues to grow, understanding the capabilities of products like the China 7016 welding rod will undoubtedly contribute to successful and efficient welding operations. Embracing such advanced welding materials will help professionals achieve optimal results and maintain the integrity of their projects, reinforcing the importance of selecting the right welding rod for the job.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025