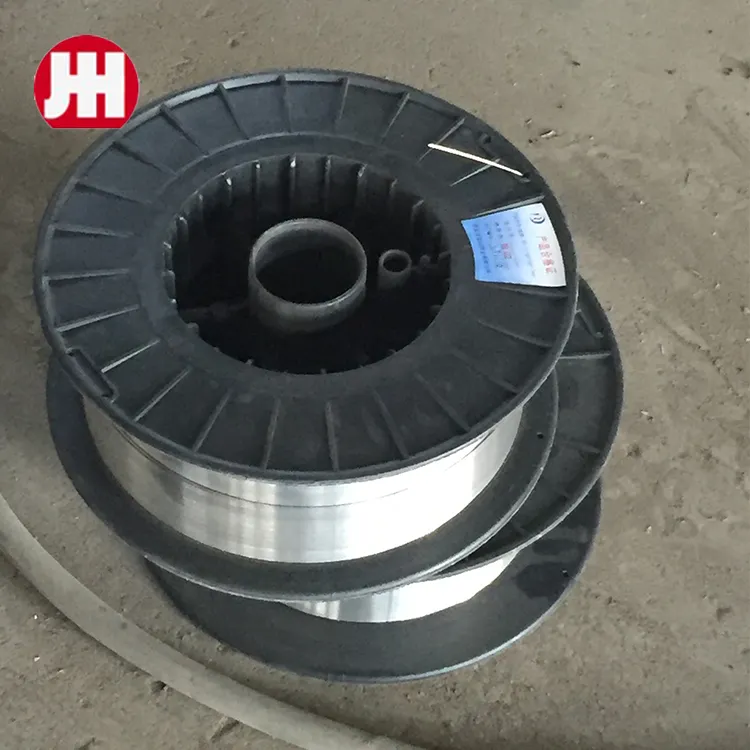

china er70s-6 welding wire 1.2mm manufacturer

Understanding the China ER70S-6 Welding Wire A Closer Look at the 1.2mm Variant

Welding is an essential process in manufacturing and construction, particularly in industries where metal structures and components are vital. A crucial aspect of welding is the type of filler material used, and in this context, the China ER70S-6 welding wire, specifically the 1.2mm variant, has garnered significant attention from professionals in the field. This article aims to explore the characteristics, applications, and advantages of this prominent welding wire.

What is ER70S-6 Welding Wire?

ER70S-6 is a type of gas metal arc welding (GMAW) wire commonly used for welding low to moderate carbon steels. The designation ER stands for electrode rigid, and the 70 indicates a minimum tensile strength of 70,000 psi. The S in the name refers to the solid wire type, while the 6 indicates its particular composition, which includes higher levels of manganese and silicon. These elements improve the wire's ability to produce sound welds, making it suitable for a variety of applications.

Features of 1.2mm ER70S-6 Welding Wire

The 1.2mm diameter of the ER70S-6 wire makes it a versatile choice for various welding machines and applications. Some notable features include

1. Ease of Use The 1.2mm diameter allows for smooth feeding through welding machines, making it easier for operators to achieve consistent and uniform welds.

2. Versatile Applications This size is particularly suitable for both thin and thick materials, allowing to weld a range of metals effectively.

3. Superior Weld Quality The unique composition of the ER70S-6 wire contributes to the production of high-quality welds with minimal spatter and excellent penetration.

4. Good Arc Stability Users appreciate the stable arc that this wire provides, which contributes to improved control during welding operations.

5. Corrosion Resistance Due to its formulation, the wire offers good resistance to oxidation and other corrosive elements, which is critical in maintaining the integrity of the weld.

Applications of ER70S-6 Welding Wire

Due to its excellent properties, the 1

.2mm ER70S-6 welding wire is widely used in several industrieschina er70s-6 welding wire 1.2mm manufacturer

- Construction From building steel frameworks to constructing pipelines, this wire is essential for providing strength and durability.

- Automotive Manufacturing The wire is often used in the production of vehicle frames and components where robust welds are critical for safety.

- Shipbuilding In the marine industry, ER70S-6 is employed to join various components of ships, ensuring that the welds are reliable enough to withstand harsh environments.

- General Fabrication It is also commonly utilized in general metal fabrication shops for a variety of tasks, including repair and maintenance work.

Advantages of Choosing China ER70S-6 Welding Wire

Opting for Chinese manufacturers of ER70S-6 welding wire can present several advantages

1. Cost-Effectiveness Chinese welding wires often come at a lower price without compromising quality, making them an attractive option for budget-conscious businesses.

2. Availability China is one of the largest producers of welding materials, ensuring a steady supply and availability of the product.

3. Variety of Options Numerous manufacturers offer different grades and types of ER70S-6 wire, allowing customers to select the right product for their specific needs.

4. Technological Advancements Many Chinese manufacturers are adopting modern techniques and technologies to enhance the quality of their welding products.

Conclusion

The China ER70S-6 welding wire, particularly in the 1.2mm diameter, is an exceptional choice for welding applications across various industries. With its excellent performance characteristics, versatility, and cost-effectiveness, it stands out as a reliable option for both professionals and hobbyists alike. As industries continue to evolve, the demand for high-quality welding materials like ER70S-6 will undoubtedly persist, solidifying its place in the welding landscape.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025