china submerged welding wire suppliers

The Landscape of Submerged Welding Wire Suppliers in China

In the realm of industrial manufacturing and construction, submerged arc welding (SAW) has emerged as a pivotal method for joining metals. This technique, distinguished by its efficiency and high-quality results, necessitates the use of specialized welding wires. As global demand for robust and reliable welding materials grows, China has established itself as a significant player in the supply chain, offering a wide range of submerged welding wire suppliers.

Understanding Submerged Arc Welding

Submerged arc welding is a process where an arc is formed between a continuously fed electrode and the workpiece. The molten weld pool is then covered by a granular flux, which not only protects the weld from contamination but also enhances the overall welding process. Given its ability to produce strong, high-quality welds, submerged arc welding is particularly popular in industries such as shipbuilding, pipeline construction, and heavy machinery manufacturing.

China's Role in the Global Market

China's strategic position as a manufacturing powerhouse has led to the development of a vast network of suppliers and manufacturers specializing in welding materials. The country is known for its competitive pricing, state-of-the-art production facilities, and an extensive range of welding consumables, including submerged welding wires. Chinese suppliers not only cater to domestic markets but also export to countries across the globe, positioning themselves as vital contributors to the global welding supply chain.

Key Suppliers and Innovations

Among the notable submerged welding wire suppliers in China are companies such as Beijing DKM, Tianjin Hengtai, and Shanghai Baoshan. These companies leverage advanced technologies and practices to ensure the quality and performance of their products. Investments in research and development have also led to innovations that enhance the properties of welding wires, such as increased tensile strength, improved fluidity, and resistance to cracking.

china submerged welding wire suppliers

For instance, some suppliers focus on developing low-temperature submerged welding wires that can perform exceptionally well in harsh environments, catering to industries that operate under extreme conditions. Moreover, the introduction of eco-friendly welding wires is on the rise, as sustainability becomes a critical consideration for manufacturers worldwide.

Quality Assurance and Standards

Given that welding is a critical component of structural integrity in various applications, quality assurance is paramount in the production of submerged welding wires. Chinese manufacturers often adhere to international standards such as ISO 9001 and AWS specifications to ensure that their products meet rigorous quality benchmarks. This adherence not only bolsters the credibility of Chinese suppliers but also reassures global customers about the reliability of the products they are purchasing.

Challenges and Considerations

Despite the advantages offered by Chinese submerged welding wire suppliers, challenges persist. The competitive landscape is crowded, leading to price wars that can sometimes compromise quality. Moreover, the continuous evolution of technology demands that manufacturers keep pace with industry advancements, necessitating ongoing investment in machinery and training. Another consideration for buyers is the need for effective communication, particularly where language barriers may exist. Establishing clear lines of communication can enhance the buyer-supplier relationship and mitigate misunderstandings regarding product specifications and quality.

Conclusion

In conclusion, China has positioned itself as a formidable force in the realm of submerged welding wire suppliers, driven by its extensive manufacturing capabilities, innovative approaches, and commitment to quality. As industries continue to evolve and demand for high-quality welding materials rises, Chinese suppliers will undoubtedly play a crucial role in meeting these needs on a global scale. For companies seeking reliable sources of submerged welding wire, exploring the offerings of Chinese suppliers presents a promising opportunity to enhance their welding processes and, ultimately, the quality of their products.

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

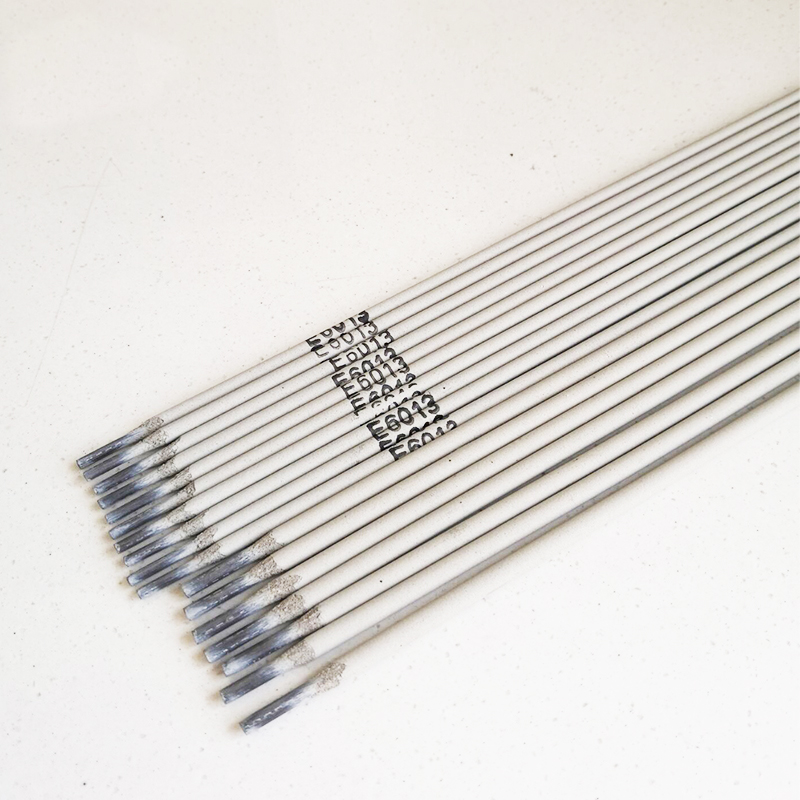

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025