china wire electrode welding suppliers

Exploring China’s Wire Electrode Welding Suppliers A Comprehensive Overview

In recent years, the demand for high-quality welding materials has seen substantial growth, particularly in industries such as construction, manufacturing, and automotive. Among the essential components in welding processes are wire electrodes, which play a crucial role in achieving strong, durable welds. China, known for its manufacturing prowess, has emerged as a leading supplier of wire electrode welding products globally. This article delves into the landscape of wire electrode welding suppliers in China, emphasizing their contributions, quality standards, and competitive advantages.

The Importance of Wire Electrodes in Welding

Wire electrodes are vital for the welding process, providing the filler material that joins two metal pieces. These electrodes can be used in various welding techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and submerged arc welding. The quality of the wire electrode directly impacts the strength and integrity of the weld. Therefore, industries seeking reliable suppliers are increasingly turning to Chinese manufacturers known for their advanced technology and production capabilities.

China’s Manufacturing Landscape

China boasts a robust manufacturing sector, facilitating the production of diverse welding products. The country's steel and alloys industry serves as a foundation for wire electrode production, allowing for the efficient and large-scale manufacture of high-quality products. Chinese suppliers often leverage advanced technologies, including automated production lines and rigorous quality control systems, to ensure consistency and reliability in their offerings.

Key Suppliers and Their Offerings

Several reputable suppliers have established themselves in the Chinese wire electrode market. Companies like Hangzhou Jinding Welding Materials Co., Ltd., and Jiangsu Sugold Welding Technology Co., Ltd., are notable examples, providing a range of products tailored for various welding applications. These suppliers offer not only traditional wire electrodes but also specialized products designed for niche markets, such as stainless steel and aluminum welding.

In addition to product variety, many suppliers engage in research and development to innovate and enhance their welding materials. This focus on innovation has positioned them to meet the evolving demands of global markets, ensuring that their products are not only compliant with international standards but also equipped to handle advanced welding techniques.

china wire electrode welding suppliers

Quality Standards and Certifications

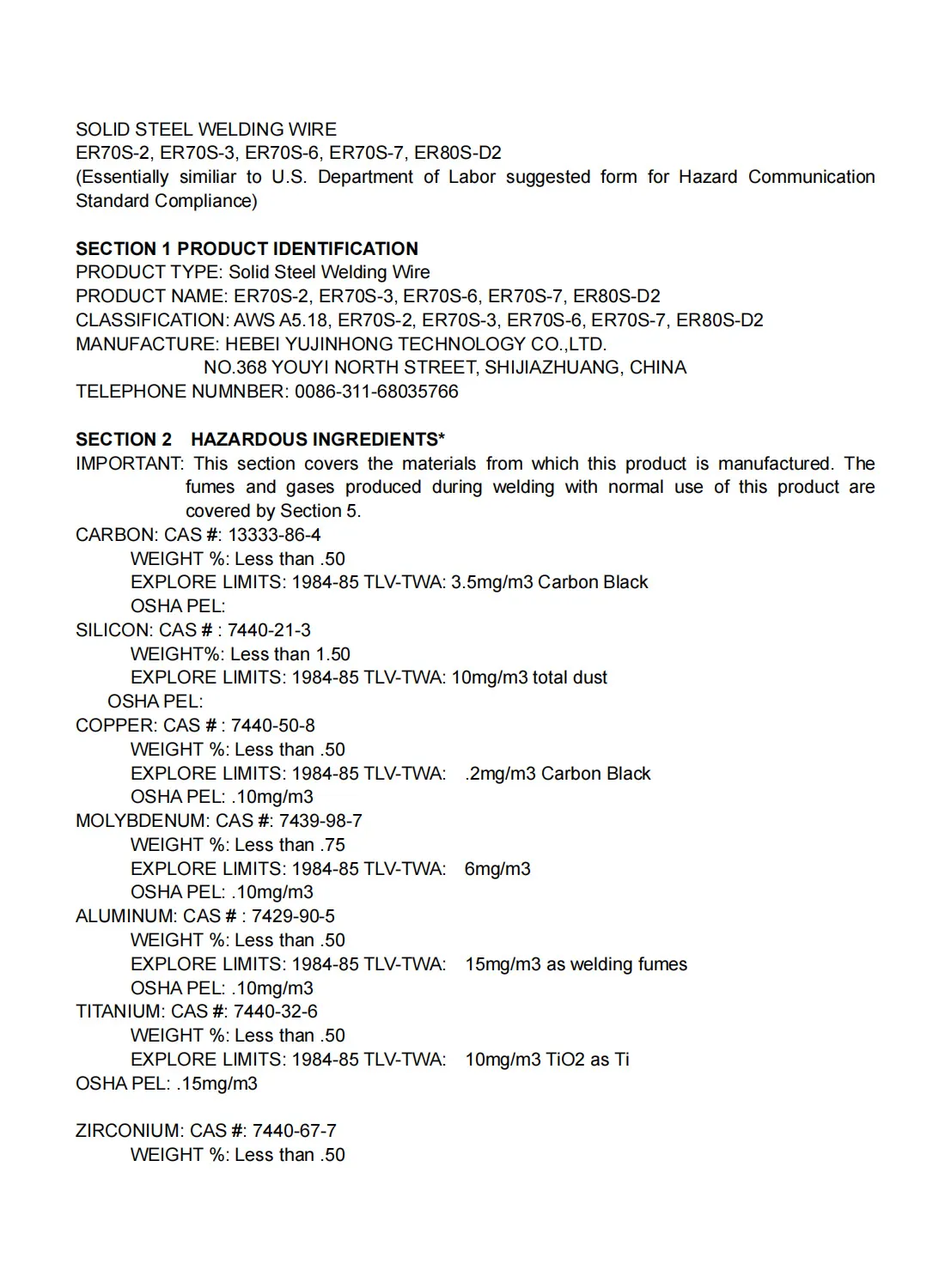

Quality is paramount in welding applications, as it directly correlates with safety and structural integrity. Leading Chinese wire electrode suppliers adhere to stringent quality standards, obtaining certifications from renowned organizations like ISO, ASME, and AWS. These certifications ensure that the products meet specific performance and safety benchmarks desired by clients worldwide.

Furthermore, many suppliers conduct thorough quality inspections and testing of their wire electrodes, evaluating factors such as tensile strength, chemical composition, and resistance to cracking. This commitment to quality assurance is critical in maintaining competitiveness in the global market.

The Competitive Advantages of Chinese Suppliers

The appeal of sourcing wire electrodes from China extends beyond cost-effectiveness. Chinese suppliers often offer competitive pricing due to lower production costs and large-scale manufacturing capabilities. Additionally, the variety of products available allows customers to find specific solutions tailored to their needs.

Moreover, many Chinese companies are committed to building robust relationships with their clients, providing excellent customer service and support. This includes flexibility in order quantities, customization options, and timely delivery, which are crucial factors for businesses operating in fast-paced industries.

Conclusion

As the welding industry continues to grow, wire electrode suppliers from China remain at the forefront, providing high-quality products that meet the needs of various sectors. With their robust manufacturing capabilities, adherence to quality standards, and competitive advantages, these suppliers are well-positioned to support global demand while fostering innovation and growth in welding technology. For companies seeking reliable wire electrode solutions, exploring partnerships with Chinese suppliers may prove to be a strategic decision in achieving operational excellence.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025