MIG Aluminum Wire Manufacturing Facilities and Their Production Process

The Role of MIG Aluminum Wire Factories in Modern Manufacturing

In the realm of manufacturing and welding, the importance of high-quality materials cannot be overstated. Among these materials, MIG (Metal Inert Gas) aluminum wire has emerged as a critical component in various applications, ranging from automotive production to aerospace engineering. The factories that produce MIG aluminum wire play a pivotal role in ensuring that industries have access to reliable and durable welding supplies.

MIG welding is a popular welding process known for its efficiency and versatility. It utilizes a continuous wire feed as an electrode, allowing for a faster welding process compared to traditional methods. Aluminum, being lightweight yet strong, is often the preferred material in numerous industries. The demand for MIG aluminum wire has consequently surged, prompting the establishment of specialized factories dedicated to its production.

MIG aluminum wire factories employ advanced technologies and methodologies to manufacture high-quality wire. The production process typically begins with sourcing high-grade aluminum alloys, which are key to achieving desirable characteristics such as corrosion resistance and weldability. These factories utilize precise melting and casting techniques to create wire that meets stringent industry standards. Furthermore, the wire is subjected to rigorous quality control measures to ensure uniformity and performance.

One notable aspect of MIG aluminum wire is its compatibility with various welding machines and techniques. Factories often produce different grades and diameters of wire to cater to diverse customer needs. For instance, automotive industries might require thinner wires for delicate components, while construction sectors may demand thicker wires for more robust applications. This flexibility makes MIG aluminum wire factories crucial in providing tailored solutions to meet specific project requirements.

mig aluminum wire factories

Moreover, the environmental impact of manufacturing processes is becoming increasingly significant in today’s industrial landscape. Many MIG aluminum wire factories are adopting sustainable practices to minimize their ecological footprint. This includes utilizing recycled aluminum materials and implementing energy-efficient production methods. By prioritizing sustainability, these factories not only contribute to environmental conservation but also help their clients achieve green certification for their projects.

In addition to manufacturing, MIG aluminum wire factories often engage in research and development activities. Continuous innovation is essential in staying competitive in the market. Factories invest in R&D to enhance the properties of aluminum wire, developing wires that offer better feedability, reduced spatter, and improved arc stability. Such advancements lead to more efficient welding processes, resulting in higher productivity and reduced operational costs for end-users.

Another key aspect of MIG aluminum wire factories is their role in providing technical support and training to their clients. Proper usage of MIG aluminum wire is crucial for achieving optimal welding results. Factories may offer workshops and training sessions to educate welders on the best practices for using aluminum wire, including techniques for preventing defects and ensuring strong welds. This support not only enhances the quality of work but also strengthens the relationship between manufacturers and customers.

In conclusion, MIG aluminum wire factories are integral to the modern manufacturing landscape. Their contributions span the entire spectrum from production and innovation to sustainability and customer support. As industries continue to evolve and demand higher quality and more efficient materials, the role of these factories will become even more significant. The future of welding and manufacturing, particularly in sectors reliant on aluminum, hinges on the continued excellence of MIG aluminum wire production, ensuring that businesses can meet the challenges of a rapidly changing world.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

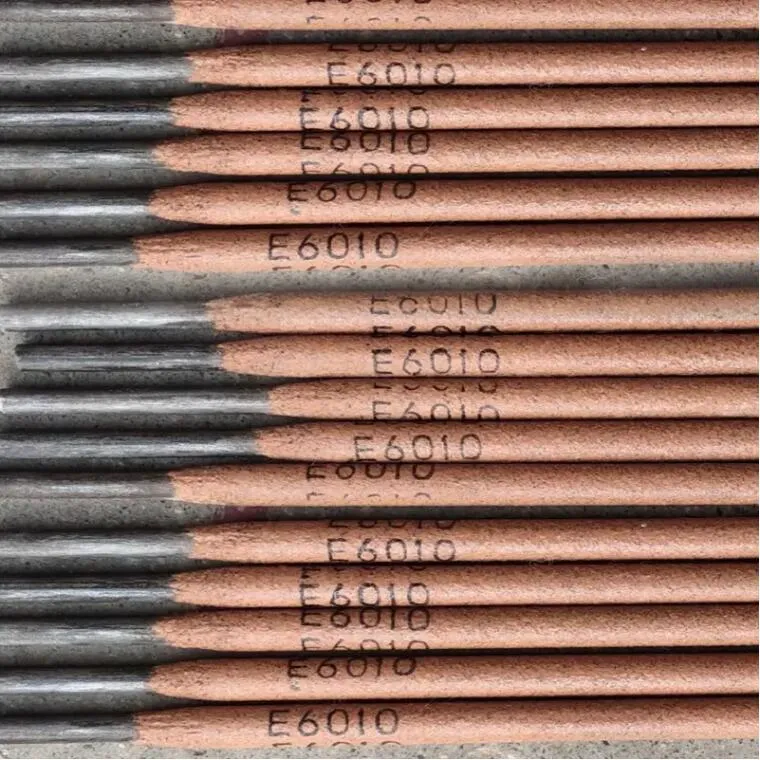

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025