stainless steel welding wire 1.6 mm manufacturers

Understanding Stainless Steel Welding Wire 1.6 mm Manufacturers and Their Importance

Stainless steel welding wire is a crucial component in various industrial applications, particularly in construction, automotive, and manufacturing. With a diameter of 1.6 mm, this specific size is often utilized in both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding processes. The efficacy and durability of the welds depend significantly on the quality of the welding wire used, making the role of manufacturers vital.

The Significance of Diameter in Welding Wire

The diameter of welding wire directly influences the welding process and the resultant welding quality. A 1.6 mm wire is favored for its versatility, allowing for fine control and precision in welding applications. It is ideal for thin materials, making it suitable for a range of projects, from intricate fabrications to structural welds. Manufacturers of stainless steel welding wire focus on this diameter to meet the varying requirements of different industries, ensuring optimal weld penetration and heat transfer.

Choosing Quality Manufacturers

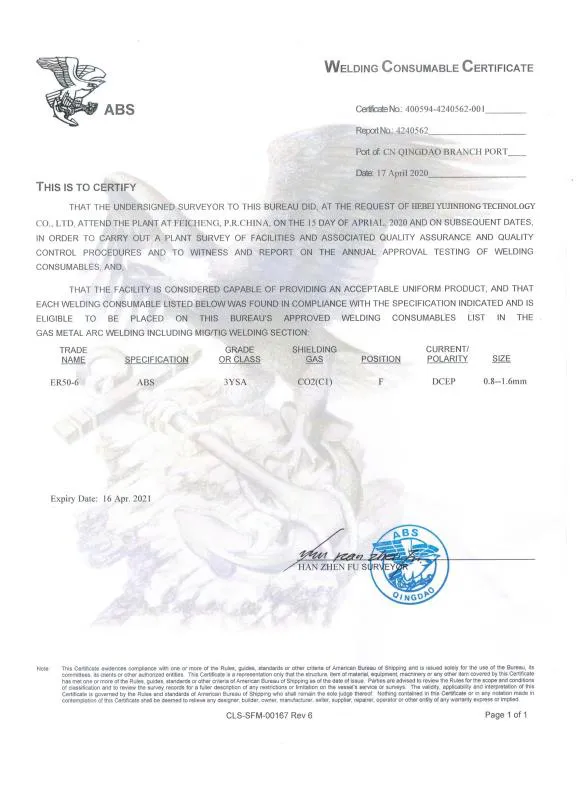

When looking for stainless steel welding wire manufacturers, it is essential to prioritize quality and reliability. High-quality welding wire should meet specified standards, such as the AWS (American Welding Society) classifications. Manufacturers who adhere to these standards are more likely to provide products that yield strong, durable welds.

Reputable manufacturers often use top-grade stainless steel, such as AISI 304 or AISI 316, which are renowned for their corrosion resistance and strength. Inspecting the material composition can help customers choose the right welding wire based on their specific needs. Therefore, understanding the manufacturer's materials and processes becomes paramount.

Innovation in Manufacturing

stainless steel welding wire 1.6 mm manufacturers

The stainless steel welding wire manufacturing industry has seen significant improvements over the years. Advanced technologies and processes, such as automated welding wire production and meticulous quality control measures, have enhanced product consistency and performance. Manufacturers invest in research and development to create wires that not only meet the demands of welding but also advance the capabilities of various welding techniques.

Moreover, eco-friendly manufacturing practices have gained traction. Sustainable practices in production reduce waste and energy consumption, responding to the increasing demand for environmentally conscious manufacturing. Manufacturers who implement such practices not only contribute to a sustainable future but also appeal to a growing market that prioritizes sustainability in their purchasing choices.

The Role of Suppliers

Manufacturers of 1.6 mm stainless steel welding wire often work in conjunction with suppliers who distribute these products to end-users. It is crucial for suppliers to maintain a strong relationship with manufacturers to ensure that they have access to high-quality products that meet industry standards. A reliable supply chain, coupled with effective communication and customer service, is vital for the success of projects relying on welding wire.

Support from manufacturers and suppliers alike can significantly impact the efficiency of the welding process. They provide essential information regarding product specifications, machining techniques, and application guidelines that ensure users can achieve optimal results.

Conclusion

In conclusion, the choice of stainless steel welding wire manufacturers is critical for achieving high-quality welding outcomes. The 1.6 mm diameter is integral to various applications, requiring manufacturers to maintain stringent quality standards and innovate continuously. As industries evolve, selecting a reliable manufacturer that emphasizes quality, sustainability, and customer support will become increasingly important for professionals in the welding sector. By prioritizing these factors, users can achieve stronger, more durable welds that meet the demanding requirements of modern applications.

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025

-

Best Stainless Steel Flux Core Wire 030 for Welding – High Strength & Clean WeldsNewsJul.06,2025

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025