High-Quality Steel Welding Wire for Durable Welds

The Importance of Steel Welding Wire in Modern Manufacturing

Steel welding wire plays a crucial role in various manufacturing processes, particularly in the construction and automotive industries. As the backbone of welding operations, this specialized wire is designed to create strong, durable bonds between steel components, ensuring structural integrity and longevity. With advancements in technology and materials science, the types of steel welding wires available today have diversified, catering to different applications and environmental conditions.

There are primarily two types of steel welding wire solid wire and cored wire. Solid wire is often used in gas metal arc welding (GMAW) and is known for its smooth feeding and stable arc characteristics. It is ideal for thin sheet metal applications and offers a clean finish with minimal spatter. On the other hand, cored wire contains a flux core that provides additional protection and enhances the welding process. This wire is particularly beneficial for outdoor welding applications where wind and other environmental factors can disrupt the shielding gas.

One of the significant advantages of steel welding wire is its ability to join dissimilar materials. In many modern manufacturing scenarios, components made from different metals need to be welded together, and the right welding wire allows for this versatility. For instance, welding wire can be formulated to accommodate combinations of stainless steel, aluminum, and low-alloy steel, expanding the range of applications in which manufacturers can engage.

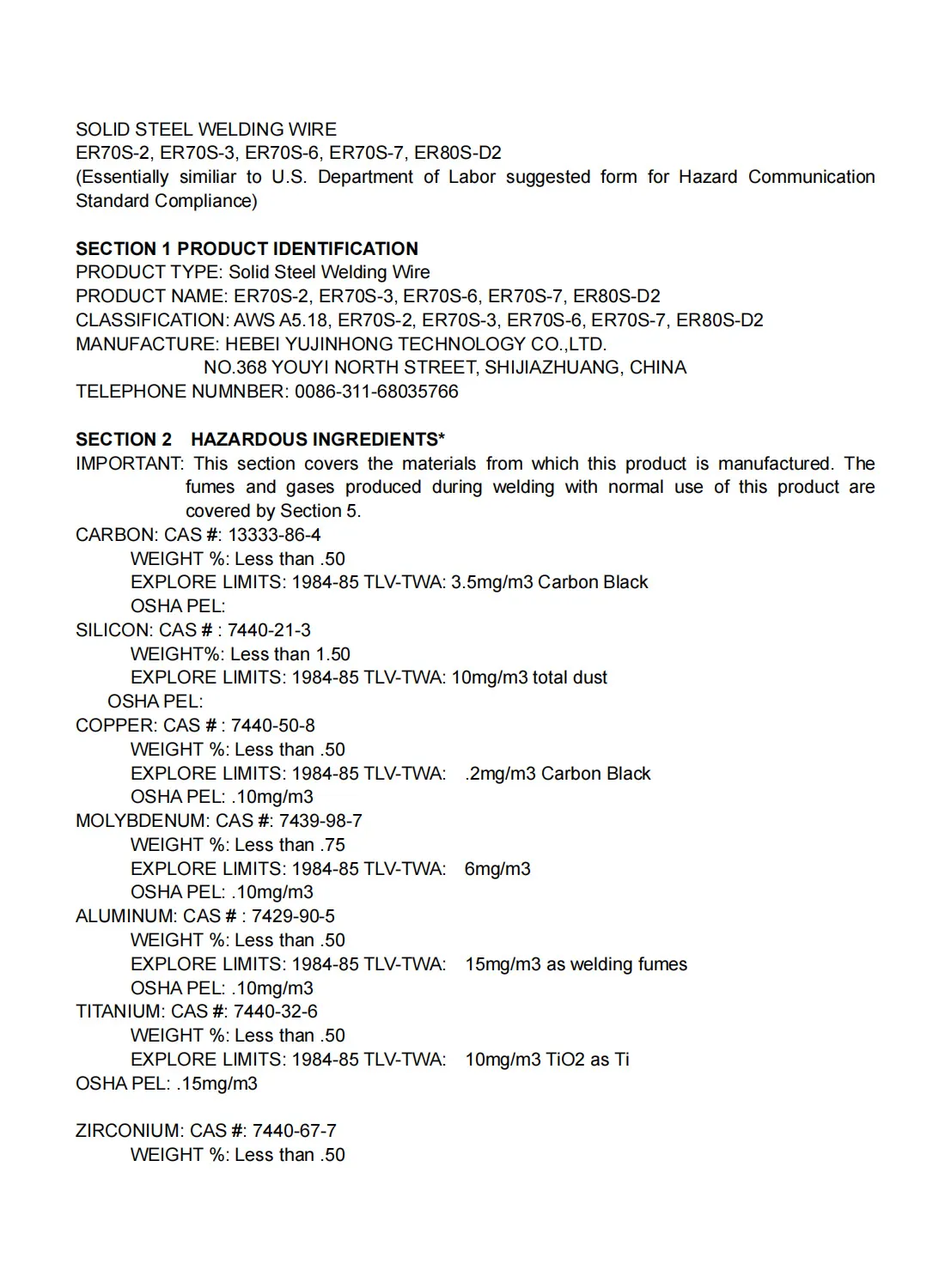

steel welding wire

Another critical aspect is the economic efficiency brought about by advanced steel welding wires. The use of high-quality welding wire not only reduces the likelihood of defects and rework but also increases the overall speed of the welding process. This efficiency ultimately translates to cost savings for manufacturers, allowing them to deliver quality products at competitive prices.

Environmental considerations are also coming into play, with the development of welding wires that minimize emissions and waste. Manufacturers are increasingly seeking eco-friendly options, and innovations in steel welding wire production are addressing these needs without compromising performance.

In conclusion, steel welding wire is a vital component in modern manufacturing, facilitating strong connections between materials while offering versatility, efficiency, and environmental considerations. As industries continue to evolve, the importance of high-quality welding wires will remain paramount, underscoring their role in the advancement of construction techniques and automotive design.

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025