1 月 . 20, 2025 04:58

Back to list

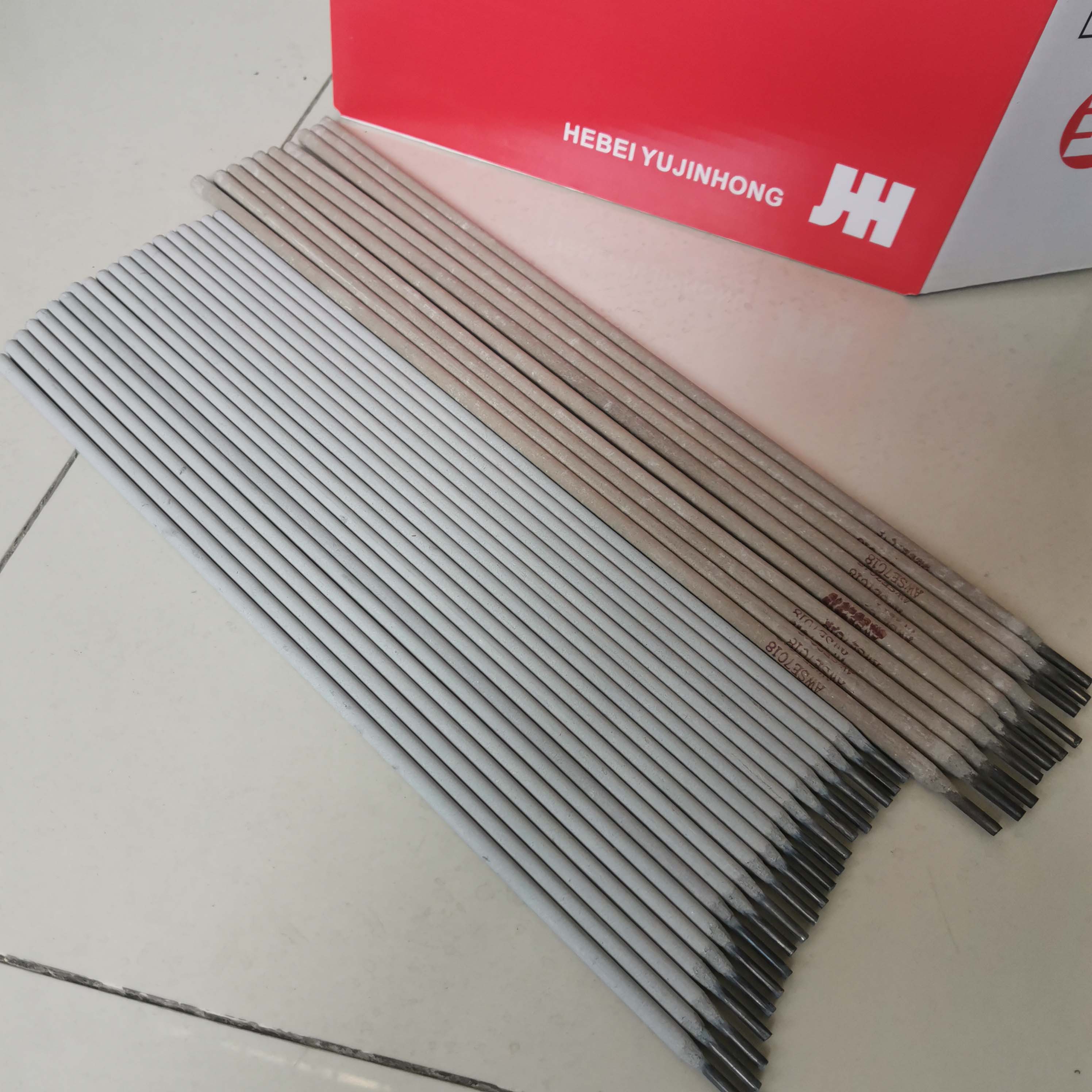

E6013 Welding Electrode Rods for carbon steel

Welding electric rods, often referred to as electrodes, are essential components in the welding industry, performing a crucial role in various welding processes. These rods are specifically designed to conduct electric current and melt into the weld joint, creating a strong, durable bond between metal pieces. Understanding the types, uses, and technical specifications of welding electric rods is vital for anyone involved in metal fabrication or industrial manufacturing, and this knowledge can significantly influence the quality and efficiency of welds.

Welding professionals emphasize maintaining the proper storage for welding rods to preserve their quality and performance. Electrodes are hydrophilic and can absorb moisture from the air, which can cause hydrogen-induced cracking or other problems. Proper storage typically involves keeping rods in a dry, temperature-controlled environment, sometimes requiring additional drying in a rod oven before use, especially in high-stakes projects involving critical welds. From a manufacturer’s perspective, producing welding electric rods involves meeting rigorous international standards such as AWS (American Welding Society) specifications, ensuring that each rod performs consistently in its designated use case. This adherence to standards builds trust with users, affirming that the product will effectively perform to its specified requirements under varying conditions. The advancement of electric welding rod technology continues to evolve, focusing on enhancing efficiency, reducing environmental impact, and improving safety for operators. For instance, low-fume rods are being developed to minimize the release of noxious particles during welding, addressing health concerns associated with prolonged exposure to welding fumes. This innovation resonates with both professional welders and hobbyists who seek to maintain safe working environments. In conclusion, the role of welding electric rods is indispensable in metal joining processes across multiple industries. Professionals and enthusiasts alike must possess comprehensive knowledge about electrode types, properties, and applications to achieve optimal results. As technological advancements push the boundaries of what’s possible, staying updated on the latest developments in welding rod composition and function is essential for anyone committed to delivering high-quality welded products. By doing so, they contribute not only to the durability and safety of their projects but also reinforce their expertise and authority in the field of welding.

Welding professionals emphasize maintaining the proper storage for welding rods to preserve their quality and performance. Electrodes are hydrophilic and can absorb moisture from the air, which can cause hydrogen-induced cracking or other problems. Proper storage typically involves keeping rods in a dry, temperature-controlled environment, sometimes requiring additional drying in a rod oven before use, especially in high-stakes projects involving critical welds. From a manufacturer’s perspective, producing welding electric rods involves meeting rigorous international standards such as AWS (American Welding Society) specifications, ensuring that each rod performs consistently in its designated use case. This adherence to standards builds trust with users, affirming that the product will effectively perform to its specified requirements under varying conditions. The advancement of electric welding rod technology continues to evolve, focusing on enhancing efficiency, reducing environmental impact, and improving safety for operators. For instance, low-fume rods are being developed to minimize the release of noxious particles during welding, addressing health concerns associated with prolonged exposure to welding fumes. This innovation resonates with both professional welders and hobbyists who seek to maintain safe working environments. In conclusion, the role of welding electric rods is indispensable in metal joining processes across multiple industries. Professionals and enthusiasts alike must possess comprehensive knowledge about electrode types, properties, and applications to achieve optimal results. As technological advancements push the boundaries of what’s possible, staying updated on the latest developments in welding rod composition and function is essential for anyone committed to delivering high-quality welded products. By doing so, they contribute not only to the durability and safety of their projects but also reinforce their expertise and authority in the field of welding.

Previous:

Latest news

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025