1 月 . 09, 2025 12:38

Back to list

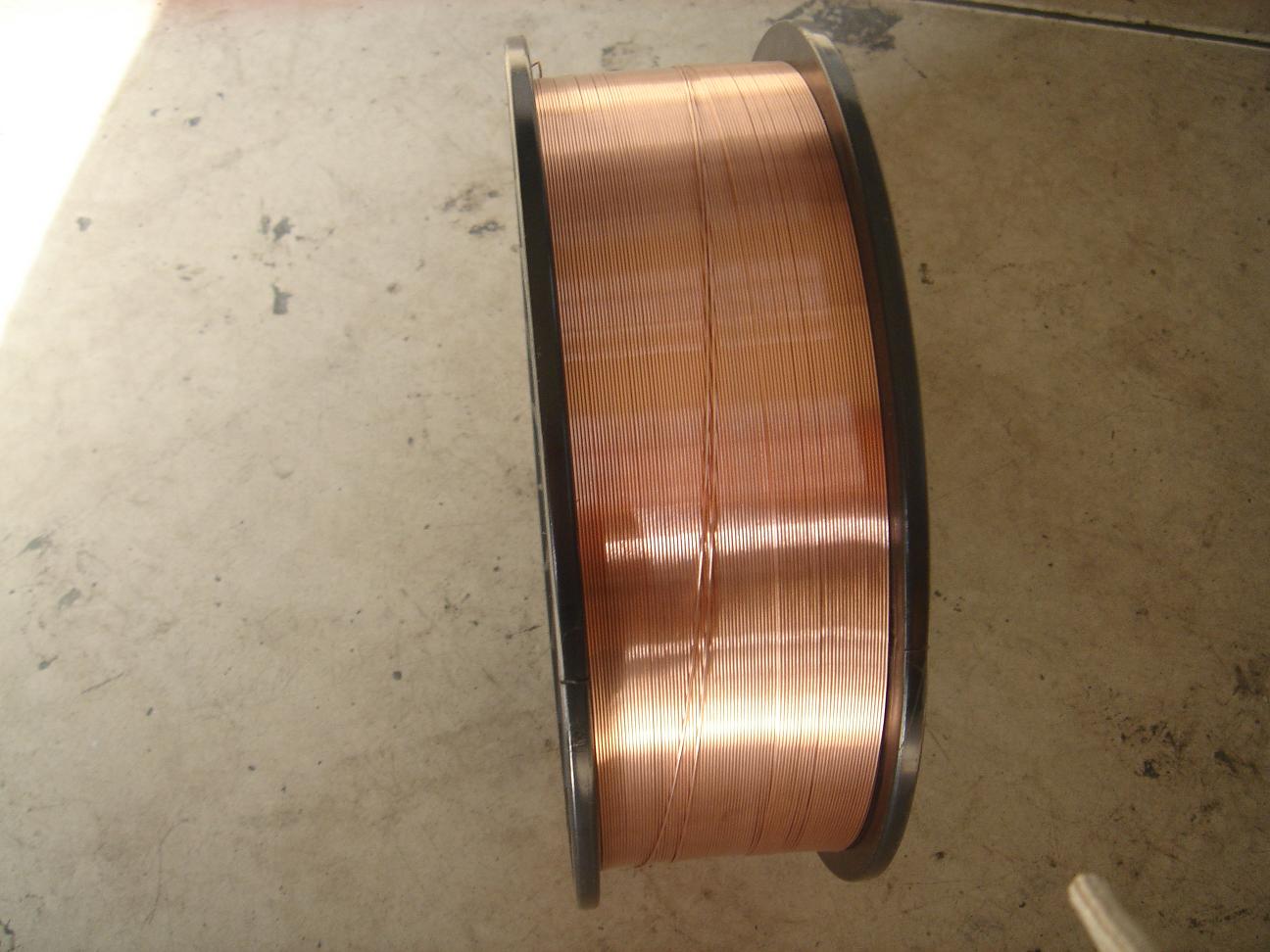

carbon steel welding electrode

When considering the purchase or use of welding electrodes, there are several key factors that influence performance, longevity, and the quality of the weld produced. As both a fundamental component in welding operations and a product keenly evaluated for quality and effectiveness, welding electrodes demand a closer look at their attributes and applications.

The consideration of electrode diameter is another critical aspect. Diameter directly affects the weld bead size and penetration depth, making it vital to align electrode size with the joint design and material thickness. A large diameter electrode deposits more material and achieves deeper penetration, suitable for thicker materials, whereas smaller diameters are better for more precise, thin material welds. Expertise in welding electrode selection stems not only from technical specifications but also from hands-on experience. Experienced welders develop an intuitive sense of how variations in electrode brand, even among those with similar specifications, can result in noticeable differences in performance and weld quality. Engaging with manufacturers and suppliers who have a robust reputation in the industry further ensures the reliability of electrodes, aligning practice with safety and quality standards. Trust in welding electrodes is built through consistent performance and adherence to industry regulations and standards. Certifications from recognized bodies, such as the American Welding Society (AWS), substantiate an electrode’s compliance with strict testing protocols. Welders should look for these certifications as a testament to the electrode's quality and its suitability for specific applications. Ultimately, the selection and application of welding electrodes are much more than a technical decision; they are an integration of expertise, experience, authority, and trustworthiness. Understanding these factors enriches the decision-making process and contributes to successful, long-lasting welds. Whether for hobbyists or industrial applications, the right electrode makes all the difference in the world of metal joining.

The consideration of electrode diameter is another critical aspect. Diameter directly affects the weld bead size and penetration depth, making it vital to align electrode size with the joint design and material thickness. A large diameter electrode deposits more material and achieves deeper penetration, suitable for thicker materials, whereas smaller diameters are better for more precise, thin material welds. Expertise in welding electrode selection stems not only from technical specifications but also from hands-on experience. Experienced welders develop an intuitive sense of how variations in electrode brand, even among those with similar specifications, can result in noticeable differences in performance and weld quality. Engaging with manufacturers and suppliers who have a robust reputation in the industry further ensures the reliability of electrodes, aligning practice with safety and quality standards. Trust in welding electrodes is built through consistent performance and adherence to industry regulations and standards. Certifications from recognized bodies, such as the American Welding Society (AWS), substantiate an electrode’s compliance with strict testing protocols. Welders should look for these certifications as a testament to the electrode's quality and its suitability for specific applications. Ultimately, the selection and application of welding electrodes are much more than a technical decision; they are an integration of expertise, experience, authority, and trustworthiness. Understanding these factors enriches the decision-making process and contributes to successful, long-lasting welds. Whether for hobbyists or industrial applications, the right electrode makes all the difference in the world of metal joining.

Previous:

Next:

Latest news

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025