1 月 . 11, 2025 09:53

Back to list

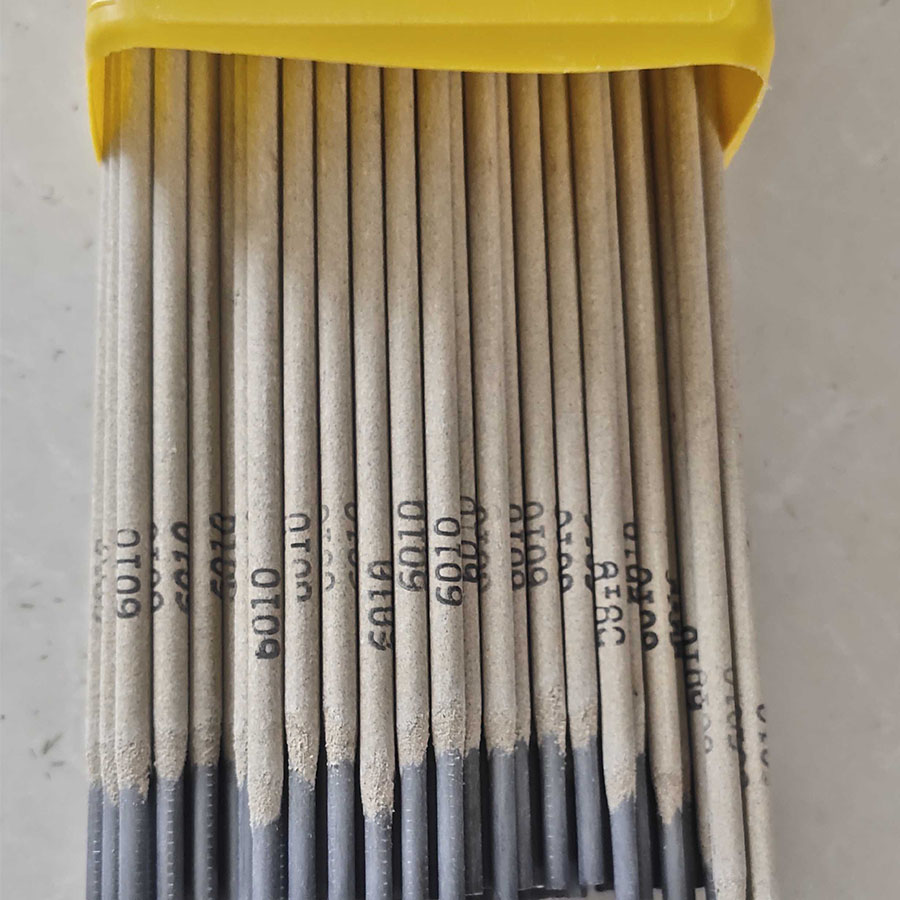

welding electrode e7016

Choosing the right welding electrode is crucial for achieving optimal results in any welding project, from constructing heavy-duty machinery to crafting intricate metal art. Among the array of options available, the E7016 welding electrode distinguishes itself as a favored choice for professionals who seek a blend of strength, versatility, and ease of use. This article illuminates the unique features, applications, and benefits of the E7016 electrode, underlining why it holds a significant place in the welding domain.

Its versatility is further showcased in maintenance and repair work. Structures that endure heavy use often develop fatigue cracks or wear that require restoration. The E7016 electrode offers the precision and adaptability needed to restore integrity without the need for extensive pre-heating, which not only saves time but also reduces energy consumption during the welding process. E7016 electrodes are designed for both AC and DC power sources, broadening their compatibility with various welding machines. This flexibility ensures that welders, whether novices or seasoned craftsmen, can access and utilize this electrode with equipment readily available in most metalworking shops. Its dependable arc start, smooth bead appearance, and ease of slag removal simplify the welding process, enhancing productivity and ensuring a high-quality finish. Trust and reliability in welding products are non-negotiable, and the E7016 electrode stands as a testament to engineering excellence. While many products on the market claim superiority, the E7016 maintains its reputation through consistent performance backed by industry standards. Its credibility is further cemented as numerous professional welders and organizations choose it as their go-to solution for challenging tasks demanding endurance and precision. In conclusion, the E7016 welding electrode offers an exemplary balance of strength, adaptability, and reliable performance. Its design considerations for reducing hydrogen embrittlement risk, ease of handling in multiple positions, and compatibility with various power sources make it a pivotal tool for those committed to quality craftsmanship. For welders seeking dependable results and a competitive edge, the E7016 is not just an option; it is the benchmark of welding excellence.

Its versatility is further showcased in maintenance and repair work. Structures that endure heavy use often develop fatigue cracks or wear that require restoration. The E7016 electrode offers the precision and adaptability needed to restore integrity without the need for extensive pre-heating, which not only saves time but also reduces energy consumption during the welding process. E7016 electrodes are designed for both AC and DC power sources, broadening their compatibility with various welding machines. This flexibility ensures that welders, whether novices or seasoned craftsmen, can access and utilize this electrode with equipment readily available in most metalworking shops. Its dependable arc start, smooth bead appearance, and ease of slag removal simplify the welding process, enhancing productivity and ensuring a high-quality finish. Trust and reliability in welding products are non-negotiable, and the E7016 electrode stands as a testament to engineering excellence. While many products on the market claim superiority, the E7016 maintains its reputation through consistent performance backed by industry standards. Its credibility is further cemented as numerous professional welders and organizations choose it as their go-to solution for challenging tasks demanding endurance and precision. In conclusion, the E7016 welding electrode offers an exemplary balance of strength, adaptability, and reliable performance. Its design considerations for reducing hydrogen embrittlement risk, ease of handling in multiple positions, and compatibility with various power sources make it a pivotal tool for those committed to quality craftsmanship. For welders seeking dependable results and a competitive edge, the E7016 is not just an option; it is the benchmark of welding excellence.

Previous:

Next:

Latest news

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025