welding rod 308l factories

Exploring the World of Welding Rod 308L Factories

Welding is an essential process in various industries, from construction to manufacturing, and the efficiency and quality of welds largely depend on the materials used. Among the various types of welding rods, the 308L stainless steel welding rod holds a paramount position due to its excellent corrosion resistance and versatility. In this article, we explore the significance of 308L welding rod factories, their production processes, and the impact they have on the welding industry.

What is 308L Welding Rod?

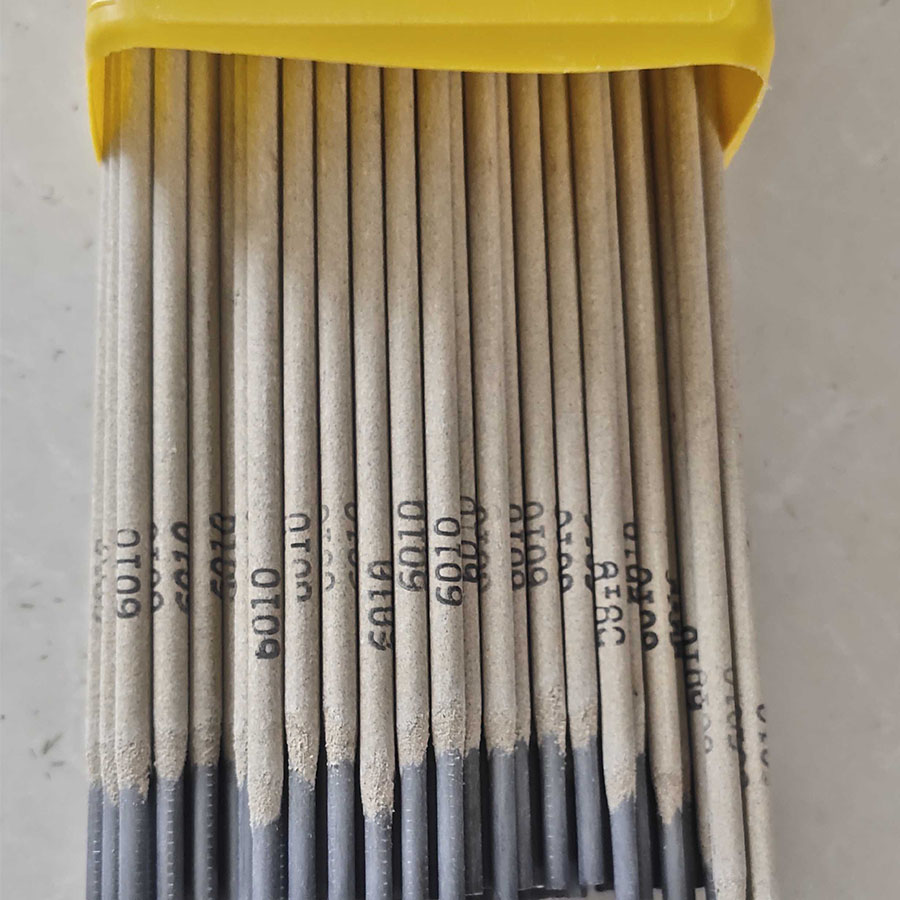

The 308L welding rod is a type of stainless steel welding electrode designed for gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) applications. The 308 denotes the alloy composition, primarily made up of chromium and nickel, which provides outstanding protection against corrosion. The L signifies the low carbon content (less than 0.03%), which minimizes carbide precipitation during welding, thus enhancing the weld's durability and performance, especially in high-temperature environments.

The Role of 308L Factories

The factories producing 308L welding rods play a crucial role in the welding supply chain. They are equipped with advanced manufacturing technologies that ensure the production of high-quality welding rods consistently. These factories source raw materials such as stainless steel and other necessary alloys, undergo rigorous quality control processes, and utilize automated machinery to produce various sizes of welding rods tailored to different welding requirements.

From small-scale operations to large industrial plants, these factories help meet the demands of various sectors, including automotive, shipbuilding, pipeline construction, and infrastructure development. The ability to provide customized products enables manufacturers to cater to specific client needs and project specifications.

Production Process

The production of 308L welding rods typically involves several critical steps

welding rod 308l factories

1. Material Preparation Raw materials are sourced and prepared, ensuring that they meet the prescribed standards for composition and quality. 2. Melting and Casting The stainless steel is melted and cast into suitable forms. This step is crucial as it dictates the rod’s overall quality and properties.

3. Extrusion The cast material is then extruded into long lengths, forming the base of the welding rods. This process involves applying heat and pressure, yielding rods of precise dimensions.

4. Pickling and Passivation After extrusion, the rods undergo pickling to remove surface impurities and improve the corrosion resistance. Passivation further enhances this property by forming a protective oxide layer on the surface.

5. Packaging and Quality Control Finally, the finished rods are packaged and subjected to quality control tests to ensure they meet industry standards before being delivered to customers.

Impact on the Industry

The existence of specialized 308L welding rod factories has positively influenced the welding industry. By ensuring consistent quality and supply, these factories allow fabricators and welders to perform tasks with greater confidence, leading to safer and more durable structures. Additionally, as industries increasingly shift towards automation and mechanization, the demand for reliable welding materials continues to grow, further establishing the importance of 308L welding rod factories.

Conclusion

In summary, 308L welding rod factories are vital players in the welding landscape, facilitating the production of high-quality welding materials that meet diverse industrial needs. Through advanced manufacturing processes and a commitment to quality, these factories not only enhance welding efficiency but also promote safety and reliability in various applications. As technology advances, the role of these manufacturers will undoubtedly expand, solidifying their importance in the global market.

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025