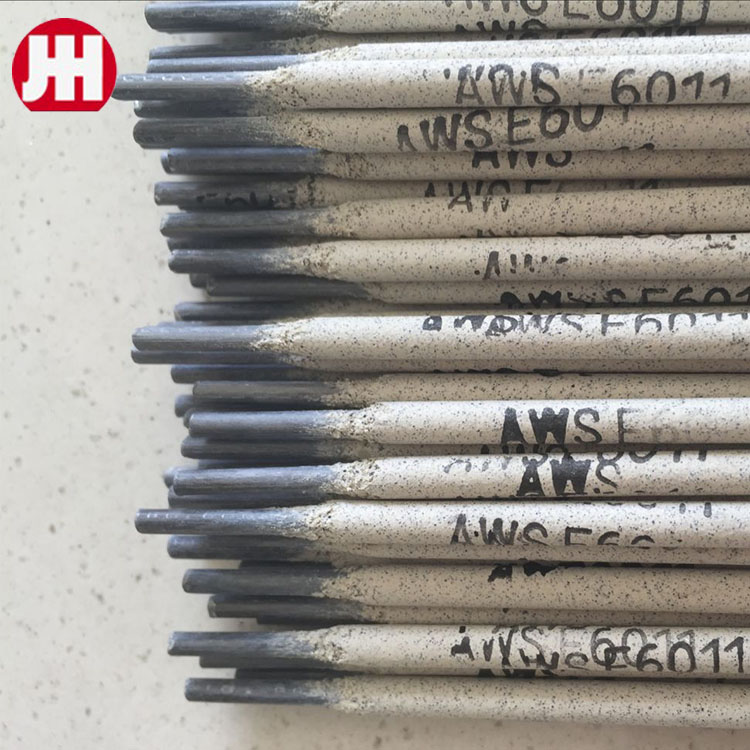

welding rods electrodes manufacturer

The Importance of Welding Rods and Electrodes in Modern Manufacturing

Welding is a critical process in various industrial applications, from construction to automotive manufacturing. At the heart of this process are welding rods and electrodes, essential components that facilitate the joining of metals and other materials. As industries continue to evolve and demand higher standards, the role of manufacturers of welding rods and electrodes becomes increasingly significant.

The Importance of Welding Rods and Electrodes in Modern Manufacturing

Electrodes, on the other hand, are primarily used in arc welding processes. They can be classified into two main types non-consumable and consumable electrodes. Non-consumable electrodes, typically made of tungsten, do not melt during the welding process. Instead, they provide a stable arc that melts the base metals and any filler material. Consumable electrodes, such as those used in MMA (Manual Metal Arc) welding, melt and become part of the weld. The selection of the right electrode type is crucial, as it impacts the quality and characteristics of the finished weld.

welding rods electrodes manufacturer

Manufacturers of welding rods and electrodes focus on several key factors to ensure the quality of their products. One of the most critical is adherence to industry standards. Compliance with international standards such as ISO and EN ensures that the welding consumables can perform consistently and reliably under various conditions. Moreover, rigorous testing during production helps identify any potential defects in the materials.

In addition to quality control, manufacturers are also innovating to meet the growing demands of modern industries. Advances in metallurgy have led to the development of specialized welding rods and electrodes that enhance performance. For instance, some electrodes are engineered to withstand extreme temperatures, making them suitable for high-heat applications in industries like aerospace and power generation. Others may be designed for specific welding techniques, such as pulsed arc welding, which requires specially formulated rods for optimal results.

Sustainability is another crucial aspect impacting the welding rod and electrode manufacturing industry. With an increasing focus on reducing environmental footprints, manufacturers are exploring ways to produce welding consumables using recycled materials and environmentally friendly processes. This shift not only aligns with global sustainability goals but also caters to the growing demand from consumers for eco-friendly products.

In conclusion, welding rods and electrodes play a vital role in the manufacturing sector, influencing the quality and integrity of welded structures. As technology advances and industries continue to push the boundaries of innovation, manufacturers must remain agile and responsive to these changes. By adhering to high standards, embracing innovation, and prioritizing sustainability, manufacturers of welding rods and electrodes can meet the needs of modern industries and drive future growth in this essential sector.

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025