Supplier of 250kg Drums for Welding Wire Solutions and Products

Supplier of Welding Wire in 250kg Drums

In the world of manufacturing and construction, welding plays an integral role in joining materials, creating strong bonds that are essential for structural integrity. When it comes to welding supplies, one of the key products needed is welding wire, which comes in various forms and specifications. Among the most popular options are the 250kg drums of welding wire, which offer numerous advantages for both small workshops and large-scale industrial operations.

Advantages of 250kg Drums

One of the primary advantages of purchasing welding wire in 250kg drums is the cost-effectiveness it offers. Bulk buying reduces the per-unit cost of the welding wire, allowing businesses to save money in the long run. For industries that rely heavily on welding, this can lead to significant savings that can be redirected to other operational expenses.

In addition to cost savings, 250kg drums are designed for practicality and efficiency. The size of the drum provides a manageable quantity for most welding jobs, reducing the frequency of orders and minimizing the downtime associated with running out of wire. This is particularly beneficial in high-output environments where productivity is paramount. By having a substantial supply on hand, welders can focus on their work without interruption.

Varieties of Welding Wire

Welding wire comes in multiple varieties, catering to different welding processes and materials. Common types include solid wire, flux-cored wire, and stainless steel wire, each designed for specific applications. Suppliers typically offer a range of wire diameters and compositions, allowing businesses to select the most suitable product for their needs.

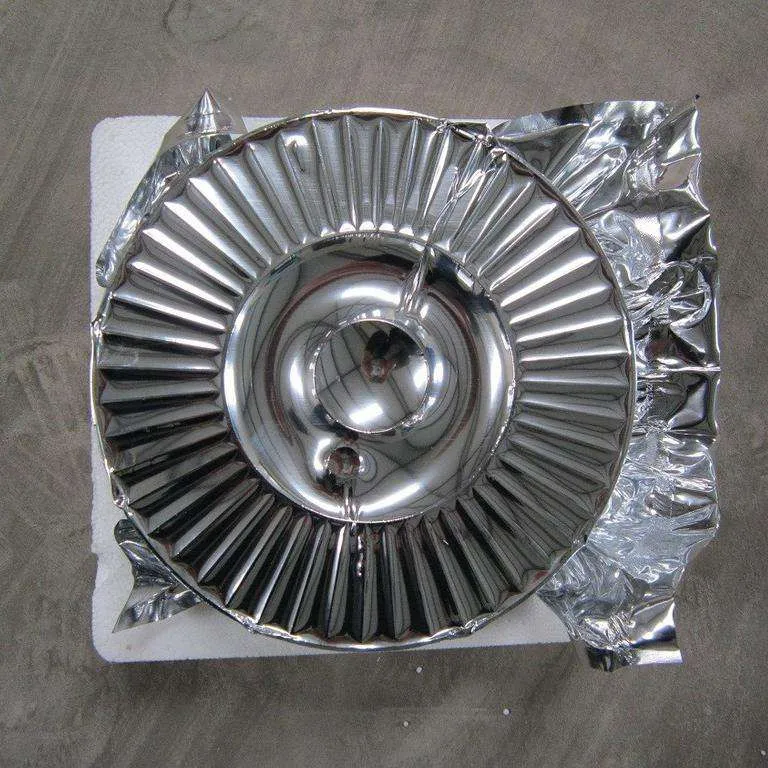

welding wire 250kg drum supplier

For instance, solid welding wire is widely used for MIG (Metal Inert Gas) welding, providing a smooth and consistent feed that enhances welding efficiency. On the other hand, flux-cored wire is ideal for outdoor applications where wind can affect shielding gases. It provides a continuous weld that does not require external shielding, making it an excellent option for construction sites.

Choosing the Right Supplier

When considering a supplier for welding wire in 250kg drums, several factors come into play. Quality should be the foremost consideration. Inferior welding wire can lead to defects, rework, and compromised structural integrity, which can ultimately cost more than savings gained from buying cheaper products. Look for suppliers who provide high-quality materials that meet industry standards and have certifications to back their claims.

Furthermore, the reputation of the supplier is crucial. A reliable supplier should have a track record of good customer service, timely deliveries, and an understanding of varying industry needs. They should also provide comprehensive technical support and advice, assisting businesses in selecting the right type of welding wire for their specific applications.

Conclusion

In summary, the use of 250kg drums for welding wire offers numerous advantages for businesses engaged in welding activities. The cost efficiency, practicality, and variety available in these drums make them an attractive option for many industries. However, the importance of choosing a reliable supplier cannot be overstated. By selecting a supplier that prioritizes quality and customer service, businesses can ensure they have the right materials to complete their projects effectively and safely. Whether it’s for construction, manufacturing, or repair work, welding wire in 250kg drums remains an indispensable resource in the welding industry.

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025