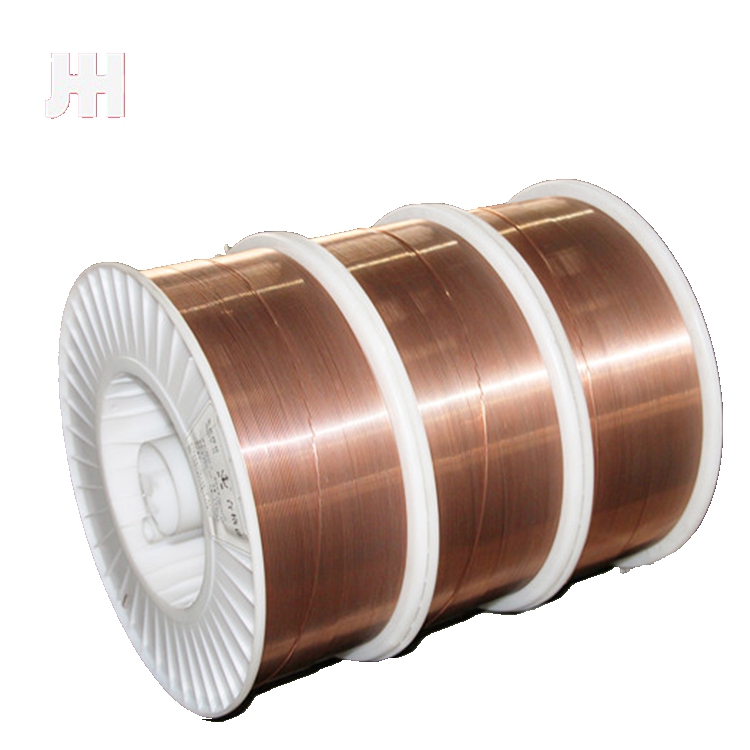

wholesale aluminum mig welding wire factories

The Growing Demand for Wholesale Aluminum MIG Welding Wire Factories

As industries evolve and technologies progress, the demand for high-quality welding supplies continues to surge. Among these indispensable materials, aluminum MIG (Metal Inert Gas) welding wire stands out due to its versatility and applicability in various sectors, including automotive, aerospace, construction, and manufacturing. This article explores the significance of wholesale aluminum MIG welding wire factories, their contributions to the market, and the challenges they may face in meeting contemporary demands.

Understanding Aluminum MIG Welding Wire

Aluminum MIG welding wire is a consumable meant for welding aluminum and its alloys through the MIG welding process. This type of welding is favored for its speed and efficiency, making it ideal for production lines and repair works. Aluminum, known for its lightweight and corrosion-resistant properties, is widely used in various applications, necessitating high-quality welding materials that ensure strong, durable joints.

The Market for Wholesale Aluminum MIG Welding Wire

Wholesale factories that specialize in aluminum MIG welding wire play a crucial role in ensuring that manufacturers and contractors have consistent access to these essential supplies. The wholesale model allows for bulk purchasing, which can significantly reduce costs for end users. This cost-effectiveness is especially important for small to medium-sized enterprises looking to manage budgets while maintaining a high standard of quality in their projects.

The demand for aluminum MIG welding wire has escalated in recent years, driven by a growing emphasis on lightweight materials in transportation and an increase in infrastructure projects. Furthermore, as more industries adopt sustainable practices, aluminum's recyclability makes it an attractive option. Thus, wholesale factories must remain agile and responsive to market trends and demands to stay competitive.

Benefits of Wholesale Suppliers

One of the primary advantages of working with wholesale aluminum MIG welding wire factories is the ability to source materials in large volumes. This not only provides cost savings but also ensures that businesses can access a consistent supply, which is critical for maintaining production schedules. Wholesale suppliers typically have established relationships with manufacturers, allowing them to offer competitive pricing and a wide range of options, from different wire diameters to specific alloy compositions.

wholesale aluminum mig welding wire factories

Additionally, wholesale factories often provide valuable expertise and support, guiding customers in choosing the right welding wire for their specific applications

. This advisory role is particularly essential for industries that may be new to aluminum welding or those that are transitioning from traditional materials to aluminum.Challenges Faced by Wholesale Aluminum MIG Welding Wire Factories

Despite the advantages, wholesale aluminum MIG welding wire factories face several challenges. One significant issue is the fluctuation in aluminum prices, which can impact production costs and pricing strategies. Factories must navigate these economic variables carefully to ensure profitability while remaining competitive.

Moreover, quality control is paramount in the welding industry. The integrity of the weld depends on the quality of the materials used, and any defects or inconsistencies in the wire can lead to catastrophic failures. Wholesale suppliers must implement stringent quality assurance measures to maintain high standards and build trust with their clients.

Technical challenges also arise with new welding technologies and techniques. Factories must keep pace with innovations in welding to provide products that meet the latest industry standards. This requires investment in research and development, which can strain resources but is vital for long-term sustainability.

Conclusion

The landscape of wholesale aluminum MIG welding wire factories is rapidly evolving, driven by market demands and technological advancements. These factories play a pivotal role in supplying high-quality materials that are essential for various industrial applications. While they face challenges such as price fluctuations and quality control, their ability to provide cost-effective solutions and expert guidance positions them as key players in the welding supply chain.

As the push for lightweight and sustainable materials continues, the significance of aluminum MIG welding wire cannot be overstated. Wholesale suppliers who adapt to these changes with agility and foresight will not only thrive in this competitive market but also contribute significantly to the advancement of welding technologies and practices across various industries.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025