Suppliers of Wholesale Cast Iron MIG Welding Wire for Industrial Use

Wholesale Cast Iron MIG Wire Suppliers A Comprehensive Guide

When it comes to welding, selecting the right materials is crucial for ensuring high-quality results. One of the essential components in MIG (Metal Inert Gas) welding is the filler material, specifically cast iron MIG wire. As the demand for cast iron welding increases in various industries, finding reliable wholesale suppliers becomes imperative for businesses looking to maintain productivity while controlling costs.

Understanding Cast Iron MIG Wire

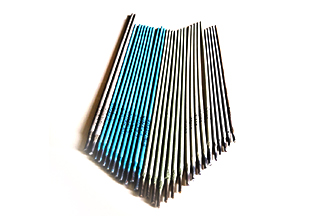

Cast iron MIG wire is specifically designed for welding cast iron materials. Cast iron is known for its high carbon content, which makes it different from other metals. This unique composition requires specialized welding wires that can handle the heat fluctuations and contraction properties of cast iron without cracking or distorting the weld joint. The two most common types of cast iron MIG wires include ER70S-6 and ER80S-D2, both offering excellent compatibility with various cast iron grades.

The Importance of Using Quality Supplies

Utilizing high-quality cast iron MIG wire is essential for achieving sound welds that meet industry standards. Poor quality wires can lead to weak joints, increased maintenance costs, and ultimately, compromised safety. Therefore, businesses should prioritize sourcing their welding materials from reputable wholesale suppliers who guarantee the quality of their products.

Finding Wholesale Suppliers

When searching for wholesale cast iron MIG wire suppliers, consider the following

wholesale cast iron mig wire suppliers

1. Reputation and Reliability Look for suppliers with a strong track record in the industry. Customer reviews, testimonials, and professional recommendations can provide valuable insight into the supplier’s reliability.

2. Product Range A good supplier should offer a range of cast iron MIG wires to meet different welding needs. This includes various specifications and sizes, ensuring that businesses can find the right product for their specific application.

3. Pricing While cost is an important factor, it should not be the only consideration. Compare prices among different suppliers, but ensure that quality and service are not compromised for lower costs.

4. Technical Support and Expertise Suppliers who provide technical support can be invaluable, especially for businesses that may not have extensive experience in welding. Look for suppliers who can offer guidance on the best products for specific applications.

5. Stock Availability and Delivery Test the responsiveness of the supplier concerning stock levels and delivery timelines. Quick turnaround and consistent availability can significantly impact workflow and productivity.

Conclusion

In the competitive world of manufacturing and fabrication, the choice of materials can greatly influence the success of a project. Reliable wholesale cast iron MIG wire suppliers play a critical role in ensuring that businesses have access to high-quality welding materials at competitive prices. By focusing on reputable suppliers, examining their product offerings, and considering additional services, companies can enhance their welding capabilities while optimizing costs. Ultimately, making informed decisions about sourcing cast iron MIG wire can lead to improved project outcomes and long-term success in the welding industry.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025