2 月 . 12, 2025 18:06

Back to list

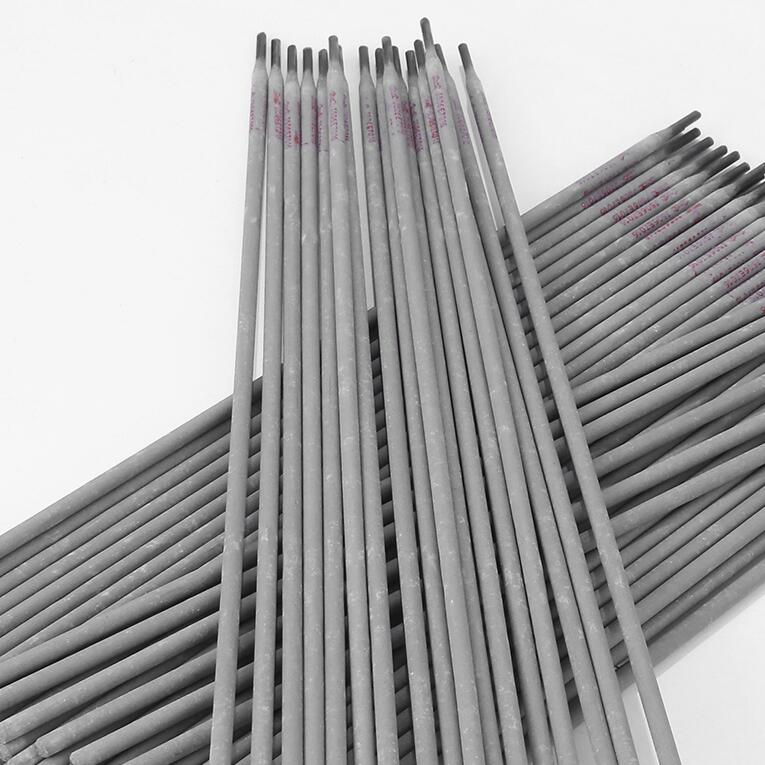

wholesale co2 gas shielded welding wire

In the ever-evolving landscape of industrial welding, the role of welding consumables is paramount, particularly CO2 gas shielded welding wire. These wires are a vital component in achieving optimal weld quality, ensuring durability, and enhancing productivity in manufacturing processes. Recognized for their ability to deliver precision and efficiency, wholesale CO2 gas shielded welding wires are a staple in the toolkit of seasoned welders.

Moreover, authentic case studies and real-world applications illustrate the superior performance of CO2 gas shielded welding wires. For instance, a fabrication company aiming to improve its welding QA metrics opted for a premium grade of this welding wire and observed a marked reduction in rejection rates due to cleaner weld finishes and reduced spatter. By documenting such concrete evidence, industry leaders can attest to the efficacy and reliability of these wires. In showcasing expertise, welding professionals often delve into the technical nuances of welding with CO2 gas shielded wire. The application involves adjusting parameters like voltage, current, and travel speed to match the wire’s characteristics with the materials being welded. Mastery of these settings can lead to high-quality welds with a fine balance of penetration and bead profile, attributes sought after in pressure vessel construction and pipeline welding. Trustworthiness in recommending CO2 gas shielded welding wires often leans on adherence to industry standards. Wires that meet specifications set by bodies such as the American Welding Society (AWS) or the International Organization for Standardization (ISO) offer assurance in their performance and applicability. Professionals understand that compliance with these standards is not just a formality but a guarantee of safety and quality. In conclusion, wholesale CO2 gas shielded welding wires offer a potent combination of efficiency, cost-effectiveness, and versatility for industrial applications. Their significance is underscored by expert testimonials, real-world applications, and adherence to stringent quality standards. By leveraging this knowledge, welding professionals can enhance their operational output, maintain high safety standards, and establish their reputation as industry leaders. As technology advances and new welding challenges emerge, the reliance on reliable and high-quality welding consumables like CO2 gas shielded wires continues to be a critical factor in the success of manufacturing processes worldwide.

Moreover, authentic case studies and real-world applications illustrate the superior performance of CO2 gas shielded welding wires. For instance, a fabrication company aiming to improve its welding QA metrics opted for a premium grade of this welding wire and observed a marked reduction in rejection rates due to cleaner weld finishes and reduced spatter. By documenting such concrete evidence, industry leaders can attest to the efficacy and reliability of these wires. In showcasing expertise, welding professionals often delve into the technical nuances of welding with CO2 gas shielded wire. The application involves adjusting parameters like voltage, current, and travel speed to match the wire’s characteristics with the materials being welded. Mastery of these settings can lead to high-quality welds with a fine balance of penetration and bead profile, attributes sought after in pressure vessel construction and pipeline welding. Trustworthiness in recommending CO2 gas shielded welding wires often leans on adherence to industry standards. Wires that meet specifications set by bodies such as the American Welding Society (AWS) or the International Organization for Standardization (ISO) offer assurance in their performance and applicability. Professionals understand that compliance with these standards is not just a formality but a guarantee of safety and quality. In conclusion, wholesale CO2 gas shielded welding wires offer a potent combination of efficiency, cost-effectiveness, and versatility for industrial applications. Their significance is underscored by expert testimonials, real-world applications, and adherence to stringent quality standards. By leveraging this knowledge, welding professionals can enhance their operational output, maintain high safety standards, and establish their reputation as industry leaders. As technology advances and new welding challenges emerge, the reliance on reliable and high-quality welding consumables like CO2 gas shielded wires continues to be a critical factor in the success of manufacturing processes worldwide.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025