2 月 . 13, 2025 11:44

Back to list

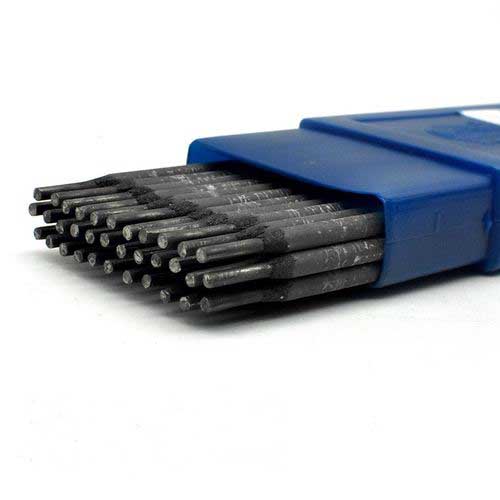

wholesale electrode for welding mig

Navigating the complex landscape of wholesale electrodes for welding MIG can be a daunting task without proper guidance. Whether you're a seasoned professional in the welding industry or just starting out, understanding the intricacies of choosing the right electrodes is paramount. This comprehensive guide provides deep insights, honed from years of experience, into the essentials of purchasing quality MIG welding electrodes in bulk.

Trustworthiness is especially crucial when purchasing wholesale. The market is vast, and choosing a reputable supplier is essential to avoid inferior quality products that can compromise job integrity. Key considerations include the supplier's industry experience, traceability of their product lines, and their reputation for reliability. Engage with suppliers who show transparency in their sourcing and manufacturing processes. Verified credentials, such as ISO certification or membership in professional organizations, serve as guarantees of their commitment to quality. In the realm of welding, sustainability is becoming an ever-important consideration. Opting for suppliers who prioritize environmentally friendly practices can help position your business as a responsible entity. Many industries are moving towards minimizing their carbon footprint, and using electrodes produced under sustainable conditions can align with these ethical values while still maintaining performance standards. Purchasing wholesale also comes with economic implications. The benefits include cost savings through reduced unit prices and better margins, especially important for large-scale operations. However, buying in bulk requires an accurate forecast of your project needs to prevent wastage and holding excess inventory that might deteriorate over time. An experienced procurement strategy involves detailed planning, assessing past consumption trends, and consulting with project managers to estimate future demands accurately. The quality of the welding outcome is heavily reliant on electrode storage conditions. Incorrect storage can lead to contaminants affecting both the electrode and the subsequent weld. Ensuring a moisture-free environment by investing in quality storage containers and dehumidifiers is advisable. Maintaining an optimal environment upholds the electrodes’ integrity and performance over time, translating to better welds and reduced wastage. In conclusion, mastering the selection of wholesale electrodes for MIG welding necessitates an interplay of Experience, Expertise, Authoritativeness, and Trustworthiness. By focusing on these pillars, companies can optimize their welding operations, resulting in higher productivity, superior end products, and sustainable business practices. The evolving landscape of welding demands continuous learning and adaptation, but with the right knowledge and partners, even the most complex challenges become manageable.

Trustworthiness is especially crucial when purchasing wholesale. The market is vast, and choosing a reputable supplier is essential to avoid inferior quality products that can compromise job integrity. Key considerations include the supplier's industry experience, traceability of their product lines, and their reputation for reliability. Engage with suppliers who show transparency in their sourcing and manufacturing processes. Verified credentials, such as ISO certification or membership in professional organizations, serve as guarantees of their commitment to quality. In the realm of welding, sustainability is becoming an ever-important consideration. Opting for suppliers who prioritize environmentally friendly practices can help position your business as a responsible entity. Many industries are moving towards minimizing their carbon footprint, and using electrodes produced under sustainable conditions can align with these ethical values while still maintaining performance standards. Purchasing wholesale also comes with economic implications. The benefits include cost savings through reduced unit prices and better margins, especially important for large-scale operations. However, buying in bulk requires an accurate forecast of your project needs to prevent wastage and holding excess inventory that might deteriorate over time. An experienced procurement strategy involves detailed planning, assessing past consumption trends, and consulting with project managers to estimate future demands accurately. The quality of the welding outcome is heavily reliant on electrode storage conditions. Incorrect storage can lead to contaminants affecting both the electrode and the subsequent weld. Ensuring a moisture-free environment by investing in quality storage containers and dehumidifiers is advisable. Maintaining an optimal environment upholds the electrodes’ integrity and performance over time, translating to better welds and reduced wastage. In conclusion, mastering the selection of wholesale electrodes for MIG welding necessitates an interplay of Experience, Expertise, Authoritativeness, and Trustworthiness. By focusing on these pillars, companies can optimize their welding operations, resulting in higher productivity, superior end products, and sustainable business practices. The evolving landscape of welding demands continuous learning and adaptation, but with the right knowledge and partners, even the most complex challenges become manageable.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025