Wholesale MIG Welding Electrodes from Top Manufacturers for High-Quality Performance

Wholesale Electrode for Welding A Comprehensive Overview of MIG Factory Solutions

Welding is an essential process in various industries, including construction, manufacturing, automotive, and aerospace. Among the diverse types of welding techniques, Metal Inert Gas (MIG) welding stands out due to its efficiency and adaptability. At the heart of this process lies the welding electrode, a critical component that enables high-quality welds. This article delves into the wholesale electrode for welding MIG factory solutions, exploring their significance, types, manufacturing processes, and the benefits of procuring them wholesale.

Understanding MIG Welding Electrodes

MIG welding employs a continuous feed of solid wire electrodes and an external shielding gas to protect the weld pool from contamination. The electrode used in MIG welding is not merely a material; it plays a pivotal role in determining the weld's integrity and quality. The wire composition directly affects the mechanical properties of the finished product—strength, ductility, and resistance to crack propagation all depend on the electrode's specifications.

Types of MIG Welding Electrodes

There is a wide variety of electrodes designed for MIG welding, with each type tailored for specific applications and materials. The most commonly used MIG electrodes include

1. ER70S-6 This is one of the most popular electrodes, suitable for welding carbon steel. It has excellent deoxidizing properties and is ideal for welding on rusty or dirty metals.

2. ER5356 Primarily used for aluminum welding, ER5356 is known for its corrosion resistance and high strength, making it suitable for marine applications.

3. ER308L This electrode is perfect for stainless steel welding, providing excellent corrosion resistance and good mechanical properties.

When selecting electrodes, factors like base metal composition, joint design, and weld environment must be considered.

Manufacturing Processes of MIG Electrodes

The manufacturing of MIG welding electrodes involves several systematic processes to ensure high quality and consistency

. Key steps in electrode production includewholesale electrode for welding mig factory

1. Raw Material Selection Quality raw materials are crucial for producing reliable electrodes. Manufacturers often source alloys and other components from reputable suppliers to ensure strength and performance.

2. Wire Drawing The selected materials undergo wire drawing, a process that reduces the diameter of the wire to the desired thickness while enhancing its strength.

3. Coating Application For some electrodes, a coating is applied to improve feeding properties and prevent oxidation. This is particularly significant for welding processes that require high precision and clean welds.

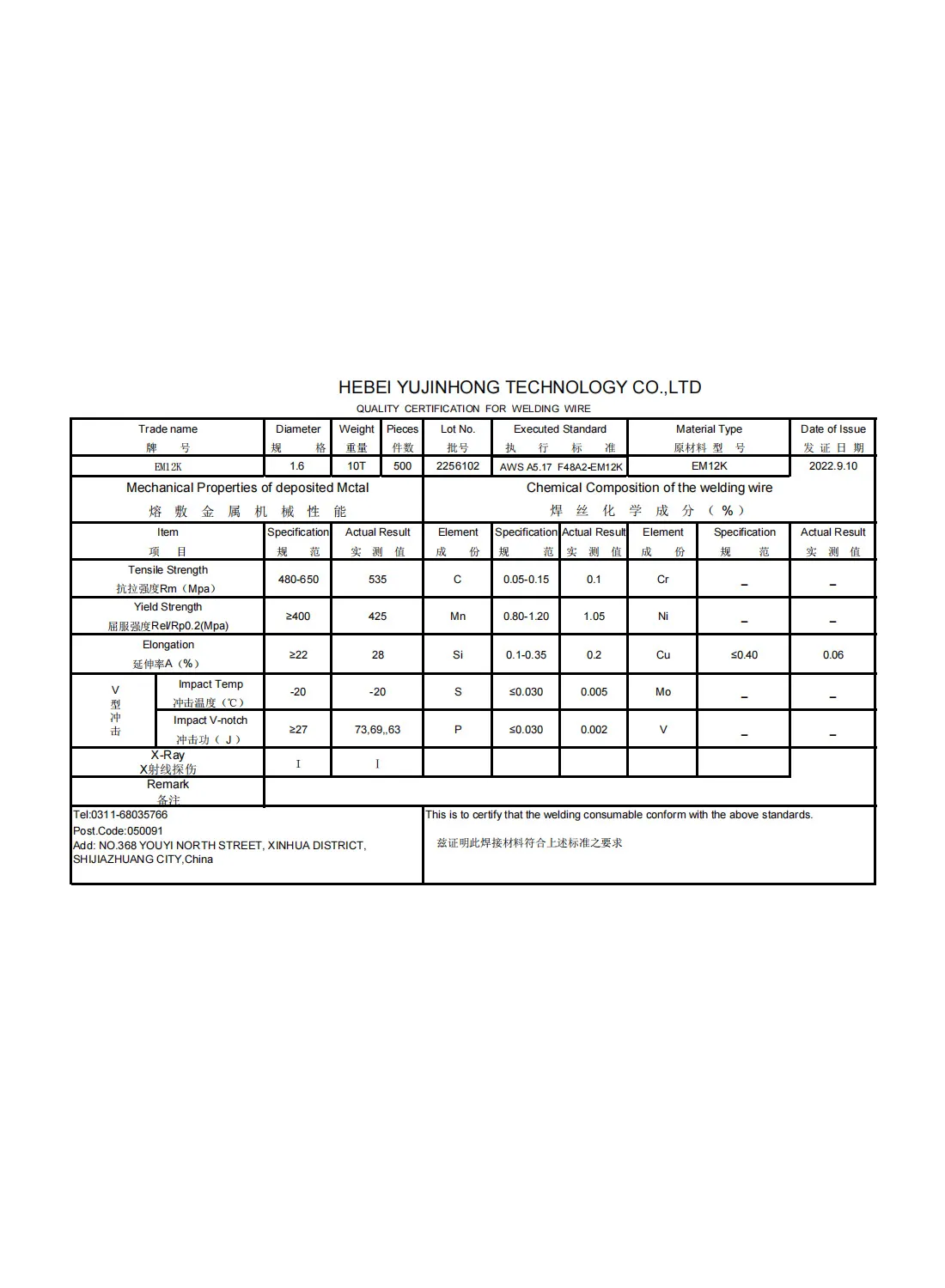

4. Quality Control The final products are subjected to rigorous quality testing, including tensile testing, bend testing, and visual inspections. This ensures they meet industry standards and specifications.

Benefits of Wholesale Procurement

Acquiring electrodes for MIG welding through wholesale channels offers numerous advantages to businesses

1. Cost-Effectiveness Purchasing in bulk significantly reduces the cost per unit. Businesses can save money that can be allocated to other essential operational needs.

2. Consistent Supply Establishing a wholesale relationship ensures a steady supply of electrodes, minimizing downtime associated with sourcing materials.

3. Customization Wholesalers often offer personalized solutions for businesses, enabling customized electrode specifications tailored to specific projects.

4. Expertise and Support Working with established wholesalers provides access to industry experts who can offer guidance and technical support, thereby enhancing operational efficiency.

Conclusion

In the landscape of welding, MIG welding electrodes are indispensable. The significance of choosing the right electrode cannot be overstated, as it directly impacts the quality of welded products. By procuring wholesale electrodes, businesses can enjoy significant savings, a consistent supply chain, and specialized support that enhances their overall manufacturing process. For industries reliant on welding, investing in quality MIG welding electrodes through wholesale channels is not just a smart move but a crucial step towards achieving excellence in their projects. Whether in automotive, construction, or any other sector where welding is a necessity, the importance of quality MIG electrodes cannot be overlooked.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025