wholesale electrodes welding 422 manufacturer

Understanding Wholesale Electrodes for Welding The Importance of Quality in Manufacturing

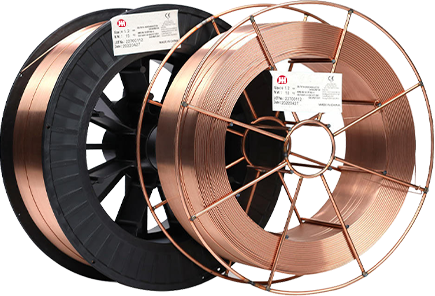

Welding is a critical process in numerous industries, including construction, automotive, shipbuilding, and manufacturing. One of the essential components in welding is the electrode. The right electrode can dramatically affect the quality of the weld and the integrity of the overall structure. For businesses or manufacturers considering bulk purchases, understanding the nuances of wholesale electrodes is vital.

What Are Electrodes?

Electrodes are conductive rods used in various welding processes, such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW). They serve as the conduit for electric current and, in many welding processes, also provide additional filler material. Electrodes come in various materials, sizes, and coatings to meet the specific demands of different applications.

The Importance of Choosing the Right Manufacturer

When sourcing wholesale electrodes, selecting a reputable manufacturer can make a significant difference in terms of product quality and reliability. A good manufacturer ensures that their electrodes conform to industry standards and possess consistency in performance. Poor-quality electrodes can lead to weak welds, increased defects, and costly repairs down the line.

Factors to Consider When Purchasing Wholesale Electrodes

1. Material Composition Different welding applications require specific types of electrodes. For instance, carbon steel electrodes are common for general-purpose welding, while stainless steel electrodes are suitable for corrosion-resistant applications. Knowing the material type needed for your projects is essential when selecting electrodes.

wholesale electrodes welding 422 manufacturer

2. Coating Type The coating on an electrode affects the arc stability, spatter, and the overall quality of the weld. There are various types of coatings, and their composition can significantly influence the usability of the electrodes. Manufacturers should provide clear information about coating types and their respective benefits.

3. Diameter and Length The size of the electrode affects not only its suitability for a job but also the efficiency of the welding process. A skilled welding technician will know which diameter and length are optimal for specific welding tasks. Bulk orders should offer a range of options to cater to different applications.

4. Production Standards Ensure that the manufacturer follows stringent quality control measures. Organizations like the American Welding Society (AWS) and the International Organization for Standardization (ISO) set standards for electrode manufacturing. Electrodes that comply with these standards are likely to ensure a high level of performance.

5. Cost and Value While cost is often a significant factor in purchasing decisions, it is essential to consider the overall value. The cheapest option may not be the best in quality. Evaluate the balance between cost and the expected lifespan and performance of the electrodes.

Benefits of Buying Wholesale

Purchasing electrodes in bulk can provide significant cost savings for businesses. Wholesale purchasing often comes with discounts that can reduce overall project costs. Additionally, maintaining a large inventory of electrodes can increase operational efficiency by minimizing downtime that occurs due to supply shortages.

Conclusion

In the realm of welding, the choice of electrodes can influence the success of a project. Whether you are a small workshop or a large-scale manufacturing plant, selecting high-quality wholesale electrodes from a reputable manufacturer is paramount. Factors such as material composition, coating type, size, compliance with production standards, and the balance between cost and value should guide purchasing decisions. Investing in quality electrodes enhances production capabilities and ultimately leads to better welding outcomes, ensuring the safety and durability of the structures and products being manufactured. By making informed choices in electrode procurement, businesses can not only improve their operational efficiencies but also uphold quality standards that are crucial for sustaining competitive advantage in the market.

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025