Wholesale Manufacturers of Stainless Steel Stick Welding Equipment and Supplies

Wholesale Stainless Stick Welding Manufacturer A Comprehensive Overview

In the ever-evolving world of manufacturing, the need for high-quality materials and reliable processes is paramount. One such critical component in various industries is stainless steel, which provides unparalleled durability and resistance to corrosion. Among the myriad ways to join stainless steel components, stick welding, also known as shielded metal arc welding (SMAW), stands out for its versatility and effectiveness. As industries seek wholesale stainless stick welding manufacturers, understanding the nuances of this process and its benefits becomes essential.

What is Stick Welding?

Stick welding utilizes a consumable electrode coated in flux to provide both filler material and a protective gas shield during the welding process. When the electrode is struck against the base metal, an electric arc is formed, creating intense heat that melts the electrode and the base material, allowing them to fuse together. The flux coating generates a shielding gas that protects the molten weld pool from atmospheric contamination, ensuring a strong, clean weld.

Advantages of Stick Welding

1. Versatility Stick welding can be used on a variety of metals, including stainless steel, cast iron, and low alloy steels. It is suitable for both indoor and outdoor projects, making it a favorite among many fabricators and manufacturers.

2. Portability Unlike other welding processes, stick welding equipment is often more portable. It does not require an extensive gas supply, making it ideal for field services and remote locations where access to power may be limited.

3. Cost-Effective For many manufacturers, especially those dealing in large volumes of welding, stick welding presents a cost-effective solution. The equipment is generally less expensive compared to other welding methods, and the consumables are often more affordable.

4. Minimal Equipment Stick welding requires minimal setup and equipment. This simplicity translates to reduced labor costs and quicker setup times—an essential factor for manufacturers looking to maximize productivity.

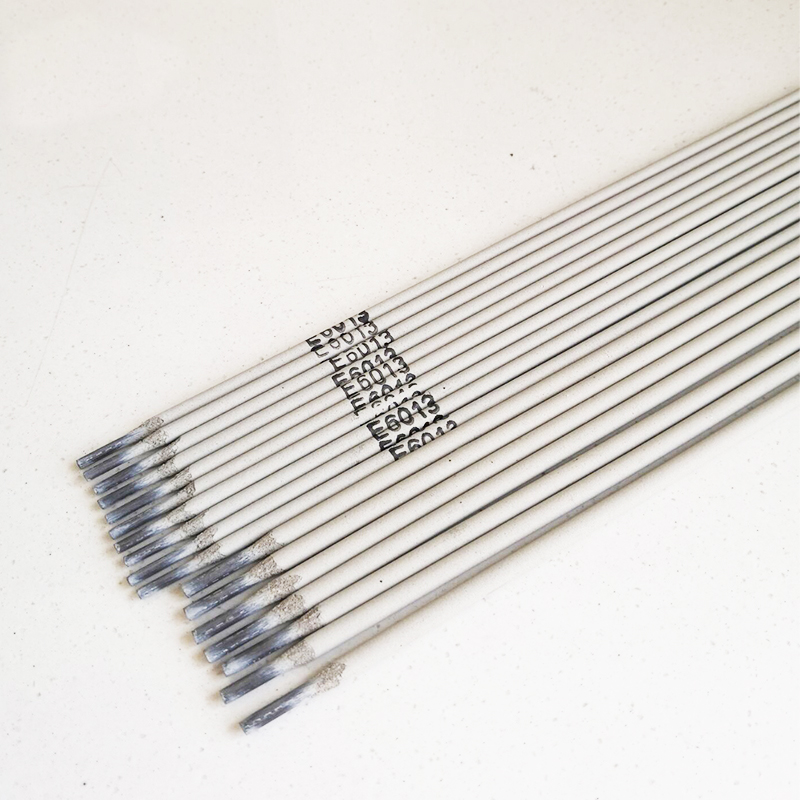

wholesale stainless stick welding manufacturer

Choosing a Wholesale Stainless Stick Welding Manufacturer

When sourcing a wholesale manufacturer for stainless stick welding, there are several key aspects to consider to ensure you select a reliable partner

1. Quality Assurance Look for manufacturers that adhere to stringent quality control measures. Certifications such as ISO 9001 indicate that a company has met international quality standards. High-quality welding materials will ensure the durability and strength of the final product.

2. Experience and Expertise Choose a manufacturer that has a proven track record in the industry. Experienced manufacturers understand the nuances of stick welding, including the right types of electrodes and techniques for different stainless steel grades.

3. Customization Options Every project has unique requirements. A reputable manufacturer should offer customization options tailored to your specific needs, whether it’s in terms of production volume, electrode specifications, or welding processes.

4. Customer Support Effective communication is vital in any business relationship. Ensure that the manufacturer provides robust customer support and is receptive to feedback and inquiries. This partnership can significantly impact the efficiency and success of your projects.

5. Sustainability Practices In today’s environmental landscape, many industries prioritize sustainable practices. Manufacturers committed to sustainability not only help to protect the environment but can also enhance the reputation of your own business.

Conclusion

As demand for stainless steel in various applications continues to rise, so does the need for efficient and reliable welding solutions. Wholesale stainless stick welding manufacturers play a crucial role in meeting this demand. By understanding the benefits of stick welding and the criteria for selecting a trustworthy manufacturer, businesses can enhance their operations and ensure the longevity of their products. Whether you are in construction, automotive, or any other industry relying on stainless steel, proper welding solutions are vital for ensuring quality and performance. Investing in a reputable wholesale manufacturer can pave the way for successful projects and satisfied customers.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025