Wholesale Suppliers for 3.15mm Welding Electrodes with Competitive Pricing Options

The Market for Wholesale Welding Electrodes A Focus on 3.15mm Size

Welding is an essential process in various industries, including construction, automotive, shipbuilding, and manufacturing. As reliance on welding continues to grow, so does the demand for quality welding materials, particularly electrodes. Among the various types available in the market, the 3.15mm welding electrode has gained popularity due to its versatility and effectiveness. This article will explore the wholesale market for 3.15mm welding electrodes, focusing on factories, production processes, and market trends.

What Are Welding Electrodes?

Welding electrodes are consumables used in electric arc welding processes. They carry the electric current that melts the metal to create a weld. Electrodes can be classified based on their coating, type (stick, TIG, MIG), and diameter. The 3.15mm size is particularly favored for its ability to provide significant penetration and good arc stability, making it suitable for various applications, from light to heavy fabrication.

The Importance of Wholesale Purchasing

For businesses involved in large-scale construction or manufacturing, purchasing welding electrodes wholesale can yield significant savings. Wholesale purchasing reduces per-unit costs and ensures a steady supply of materials. Factories producing 3.15mm welding electrodes offer bulk purchasing options that cater to the needs of contractors and companies that require large quantities of electrodes for their projects.

The Production Process of 3.15mm Welding Electrodes

Manufacturing welding electrodes involves several key steps

1. Material Selection High-quality raw materials, including mild steel, stainless steel, and coating materials, are selected to produce electrodes that meet industry standards.

2. Formulation of Coating The coating on the electrode is crucial for determining its performance. The right combination of materials impacts factors such as slag formation, arc stability, and usability in various positions.

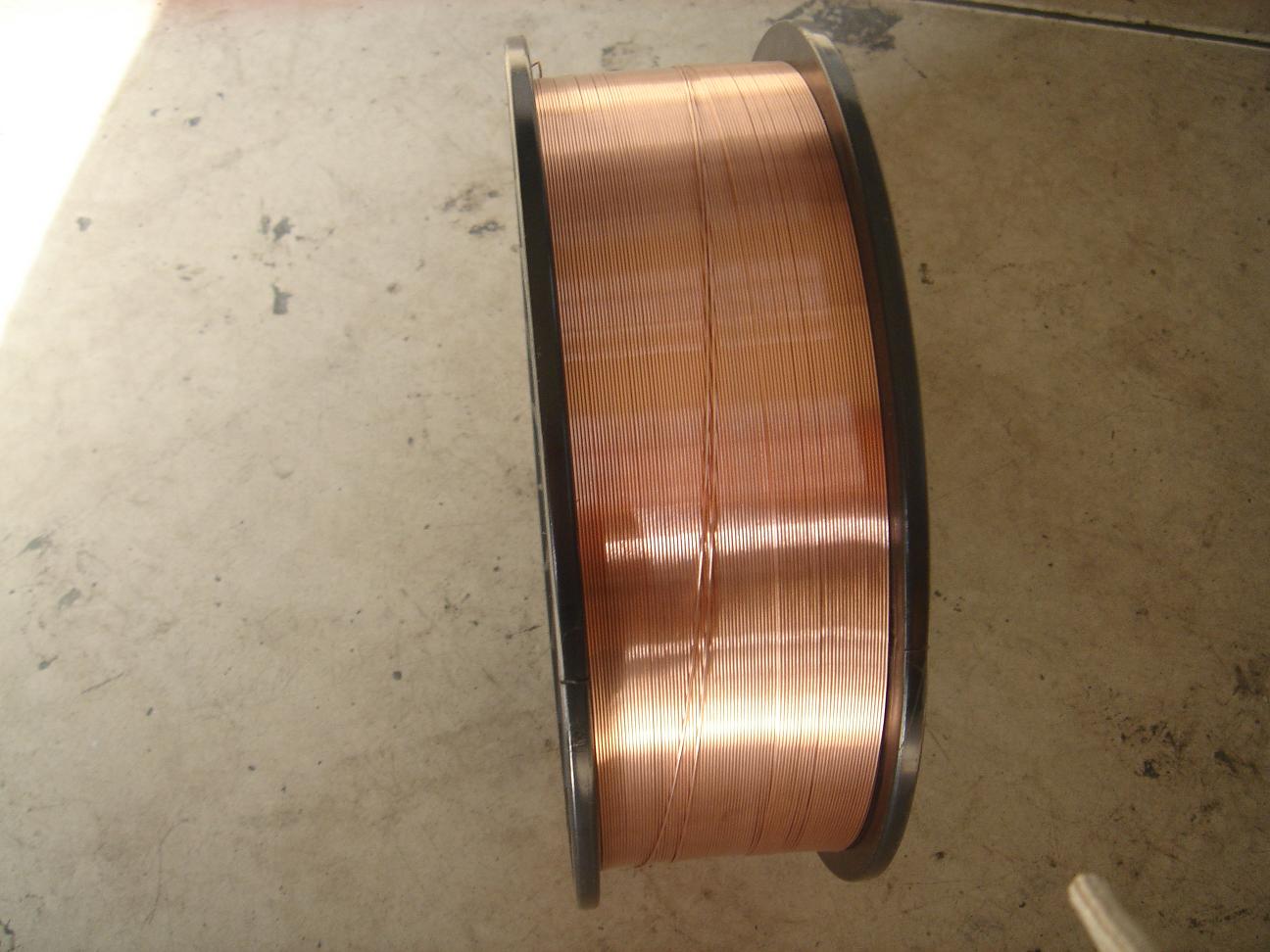

3. Drawing and Cutting The production process begins with drawing the wire to the desired diameter. For 3.15mm electrodes, precise measurements are critical to ensure compatibility with standard welding machines. After forming, the wire is cut into lengths suitable for use.

4. Applying Coating The electrode wire is coated through processes like extruding, dipping, or spraying. The coating is then cured to ensure proper adhesion and performance.

5. Quality Control Rigorous testing, including tensile strength and conductivity tests, ensures each batch meets performance specifications before being released for wholesale distribution.

wholesale welding electrode 3.15mm factories

Finding the Right Factory

When seeking wholesale 3.15mm welding electrodes, it is essential to choose a reliable factory. Businesses should look for

- Certifications Factories should have ISO certifications or other industry-related certifications that validate their adherence to quality standards.

- Experience Established manufacturers with a proven track record in producing welding electrodes often utilize advanced technologies and processes, ensuring better quality and reliability.

- Customer Reviews Feedback from other buyers can provide insights into a factory's reputation and product performance.

- Technical Support A good manufacturing partner should be able to offer technical assistance, helping customers select the right electrodes for their specific applications.

Market Trends

The welding electrode market has shown resilience and growth, primarily due to developments in various industries. A few current trends include

- Sustainability Increasingly, manufacturers are focusing on sustainable practices, using eco-friendly materials, and reducing waste during production.

- Innovation Ongoing research is leading to the development of advanced electrodes that offer enhanced performance characteristics, such as improved arc stability and increased resistance to defects.

- Globalization The rise of international trade has opened up markets for factories that produce 3.15mm welding electrodes, allowing them to reach a broader range of customers and clients worldwide.

Conclusion

As the demand for welding services continues to increase, the wholesale market for 3.15mm welding electrodes remains a vital segment of the industry. Factories dedicated to producing high-quality welding electrodes play a crucial role in providing the necessary materials for various applications. By focusing on quality, sustainability, and innovation, manufacturers can meet the evolving needs of the welding industry, ensuring a successful partnership with businesses reliant on these essential consumables.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025