Nuus

-

In the bustling shipyard, welding tasks are not uncommon; nonetheless, they demand an unwavering commitment to safety protocols to prevent tragedies.Lees meer

In the bustling shipyard, welding tasks are not uncommon; nonetheless, they demand an unwavering commitment to safety protocols to prevent tragedies.Lees meer -

The electrode coating refers to the coating layer applied to the surface of the welding core.Lees meer

The electrode coating refers to the coating layer applied to the surface of the welding core.Lees meer -

The selection principle of welding rod plays a crucial role in welding engineering, as it directly affects the quality, performance, economy, and feasibility of welding joints and welding processes. The following are the principles for selecting welding rods summarized from multiple perspectives.Lees meer

The selection principle of welding rod plays a crucial role in welding engineering, as it directly affects the quality, performance, economy, and feasibility of welding joints and welding processes. The following are the principles for selecting welding rods summarized from multiple perspectives.Lees meer -

As a key material in welding processes, welding rods have a series of significant characteristics that not only reflect their important role in the welding process, but also determine their wide applicability in different application fields. The following is a detailed explanation of the characteristics of welding rods.Lees meer

As a key material in welding processes, welding rods have a series of significant characteristics that not only reflect their important role in the welding process, but also determine their wide applicability in different application fields. The following is a detailed explanation of the characteristics of welding rods.Lees meer -

Carbon steel welding wire, as a widely used welding material, has multiple significant characteristics that together ensure its superior performance and reliability in various welding scenarios. The following is an overview of the main characteristics of carbon steel welding wire.Lees meer

Carbon steel welding wire, as a widely used welding material, has multiple significant characteristics that together ensure its superior performance and reliability in various welding scenarios. The following is an overview of the main characteristics of carbon steel welding wire.Lees meer -

Copper coated welding wire, as an important welding material, has significant characteristics and a wide range of application fields. The following is a detailed explanation of its characteristics and application areas.Lees meer

Copper coated welding wire, as an important welding material, has significant characteristics and a wide range of application fields. The following is a detailed explanation of its characteristics and application areas.Lees meer -

As the core material in welding processes, welding rods have a wide range of applications, covering almost all industries that require metal connections. The following is a detailed explanation of the application fields of welding rods.Lees meer

As the core material in welding processes, welding rods have a wide range of applications, covering almost all industries that require metal connections. The following is a detailed explanation of the application fields of welding rods.Lees meer -

Carbon steel welding wire, as a key material in welding processes, has a wide range of applications, covering multiple important industries. The following is an overview of the main application areas of carbon steel welding wire.Lees meer

Carbon steel welding wire, as a key material in welding processes, has a wide range of applications, covering multiple important industries. The following is an overview of the main application areas of carbon steel welding wire.Lees meer -

In the construction industry, safety protocols are critical, especially when working with hazardous materials like acetylene cylindersLees meer

In the construction industry, safety protocols are critical, especially when working with hazardous materials like acetylene cylindersLees meer -

Carbon steel is a common metal material widely used in various fields.Lees meer

Carbon steel is a common metal material widely used in various fields.Lees meer -

The dangerous incident involving the welder in a hardware store who utilized oxygen instead of compressed air during a compressor repair underscores critical safety failures and errors in the welding industry.Lees meer

The dangerous incident involving the welder in a hardware store who utilized oxygen instead of compressed air during a compressor repair underscores critical safety failures and errors in the welding industry.Lees meer -

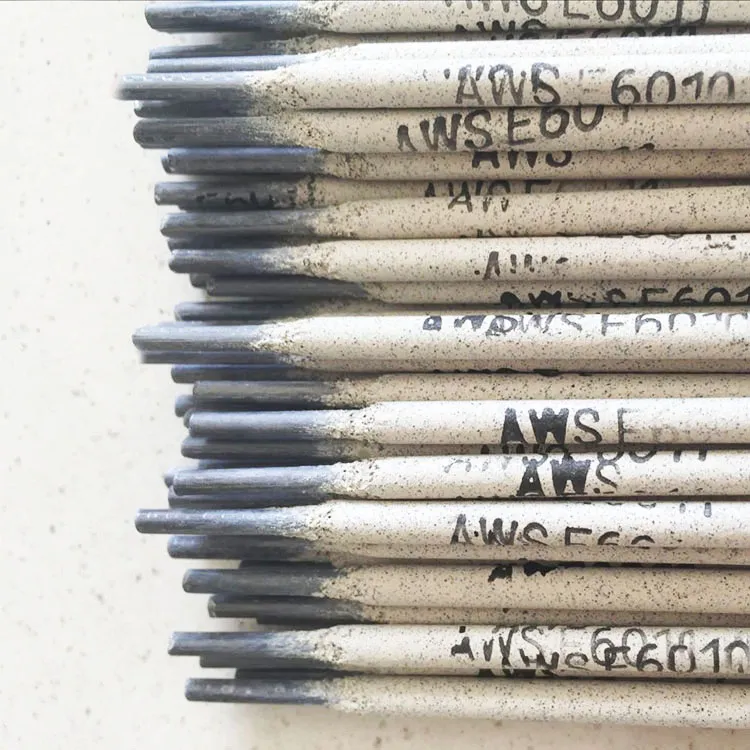

E6010 electrode is a high-cellulose sodium type vertical downward electrode, which conforms to my country's GB E4310 standard and is equivalent to the international standard AWS E6010.Lees meer

E6010 electrode is a high-cellulose sodium type vertical downward electrode, which conforms to my country's GB E4310 standard and is equivalent to the international standard AWS E6010.Lees meer