Nuus

-

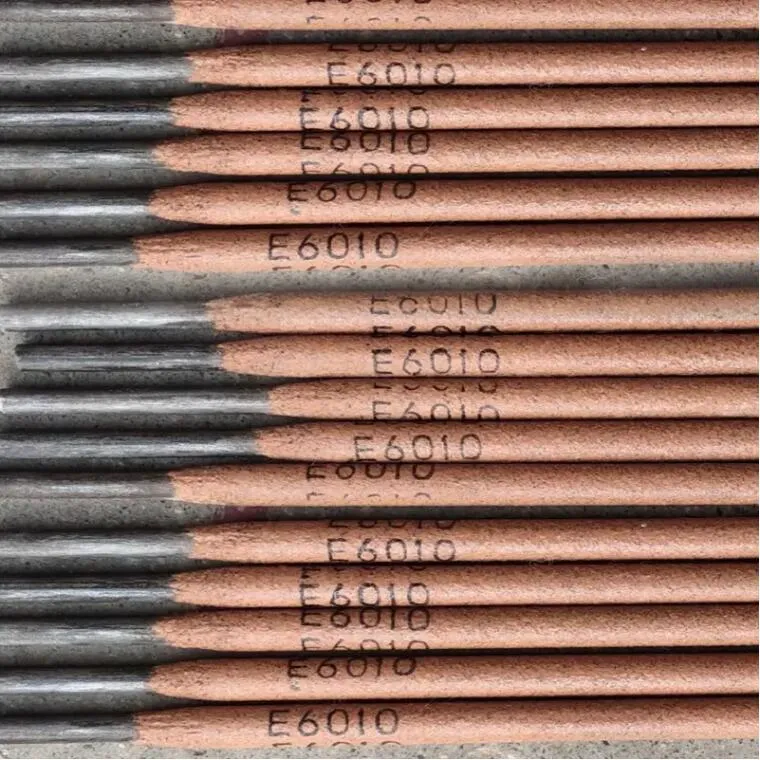

In the diverse world of welding, understanding the specifications and applications of various electrodes is crucial for achieving optimal results.Lees meer

In the diverse world of welding, understanding the specifications and applications of various electrodes is crucial for achieving optimal results.Lees meer -

Welding is a vital skill used in various industries, from construction to automotive repair. As a beginner welder or an experienced fabricator, understanding the nuances of different welding rods is crucial for achieving quality welds. One of the most popular welding rods is the 7018 welding rod, known for its versatility and strength.Lees meer

Welding is a vital skill used in various industries, from construction to automotive repair. As a beginner welder or an experienced fabricator, understanding the nuances of different welding rods is crucial for achieving quality welds. One of the most popular welding rods is the 7018 welding rod, known for its versatility and strength.Lees meer -

In the quiet confines of a pesticide factory, the routine task of welding took a tragic turn when a seasoned welder, tasked with welding a baffle inside a breeding pot, made a critical error.Lees meer

In the quiet confines of a pesticide factory, the routine task of welding took a tragic turn when a seasoned welder, tasked with welding a baffle inside a breeding pot, made a critical error.Lees meer -

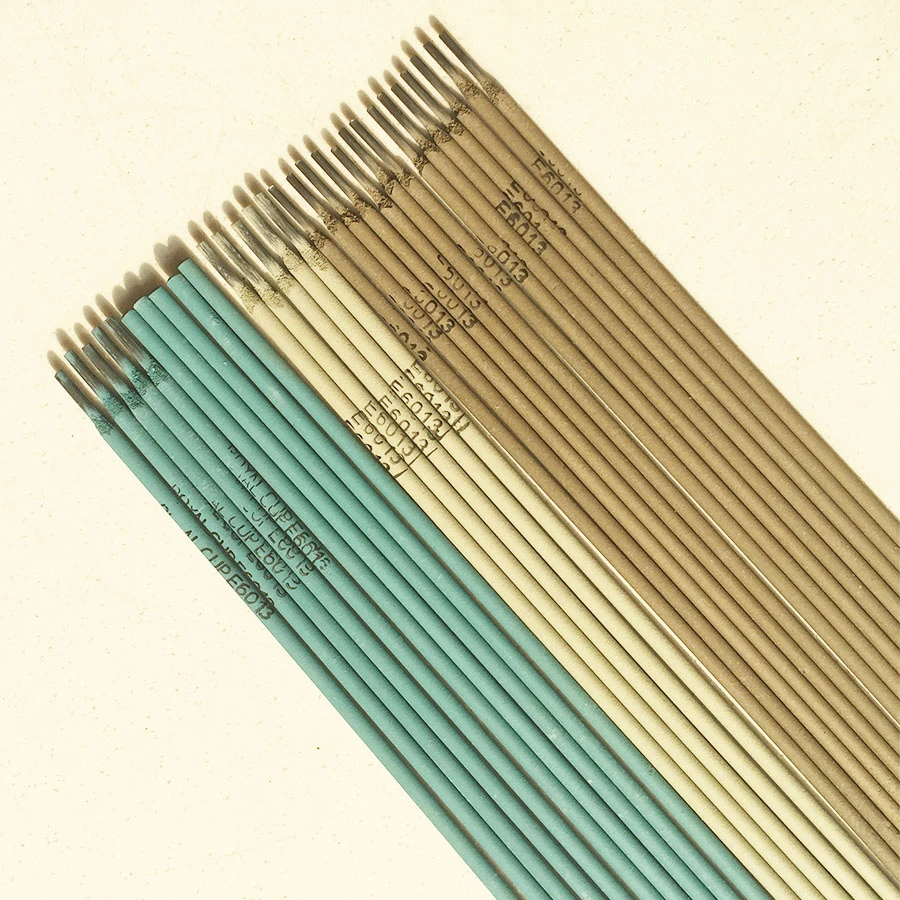

Welcome, fellow welders and metal magicians, to the grand showdown between two of the welding world’s heavyweight champions: E6013 and E6011! If you’ve found yourself daydreaming about the perfect welding rod while sipping your morning coffee (and let’s be honest, who hasn’t?), you’re in the right place. Prepare for a humorous and enlightening journey into the world of welding rods, their differences, and maybe even a little comedy along the way.Lees meer

Welcome, fellow welders and metal magicians, to the grand showdown between two of the welding world’s heavyweight champions: E6013 and E6011! If you’ve found yourself daydreaming about the perfect welding rod while sipping your morning coffee (and let’s be honest, who hasn’t?), you’re in the right place. Prepare for a humorous and enlightening journey into the world of welding rods, their differences, and maybe even a little comedy along the way.Lees meer -

Welcome to the thrilling world of welding! Today, we're diving deep into a classic debate that every welding enthusiast has faced at least once: E6013 vs E7018.Lees meer

Welcome to the thrilling world of welding! Today, we're diving deep into a classic debate that every welding enthusiast has faced at least once: E6013 vs E7018.Lees meer -

If you're diving into the world of welding, you've likely stumbled upon the term "E7016 welding rod." But what exactly is it used for? Grab your welding helmet, and let’s spark up an enlightening discussion about this versatile welding rod that's got every welder buzzing!Lees meer

If you're diving into the world of welding, you've likely stumbled upon the term "E7016 welding rod." But what exactly is it used for? Grab your welding helmet, and let’s spark up an enlightening discussion about this versatile welding rod that's got every welder buzzing!Lees meer -

When welding, welders need to take comprehensive protective measures to ensure their safety and health.Lees meer

When welding, welders need to take comprehensive protective measures to ensure their safety and health.Lees meer -

In an unsettling incident, a welder inadvertently caused a fire while changing an acetylene cylinder, shedding light on the importance of adhering to essential safety protocols in the workplace.Lees meer

In an unsettling incident, a welder inadvertently caused a fire while changing an acetylene cylinder, shedding light on the importance of adhering to essential safety protocols in the workplace.Lees meer -

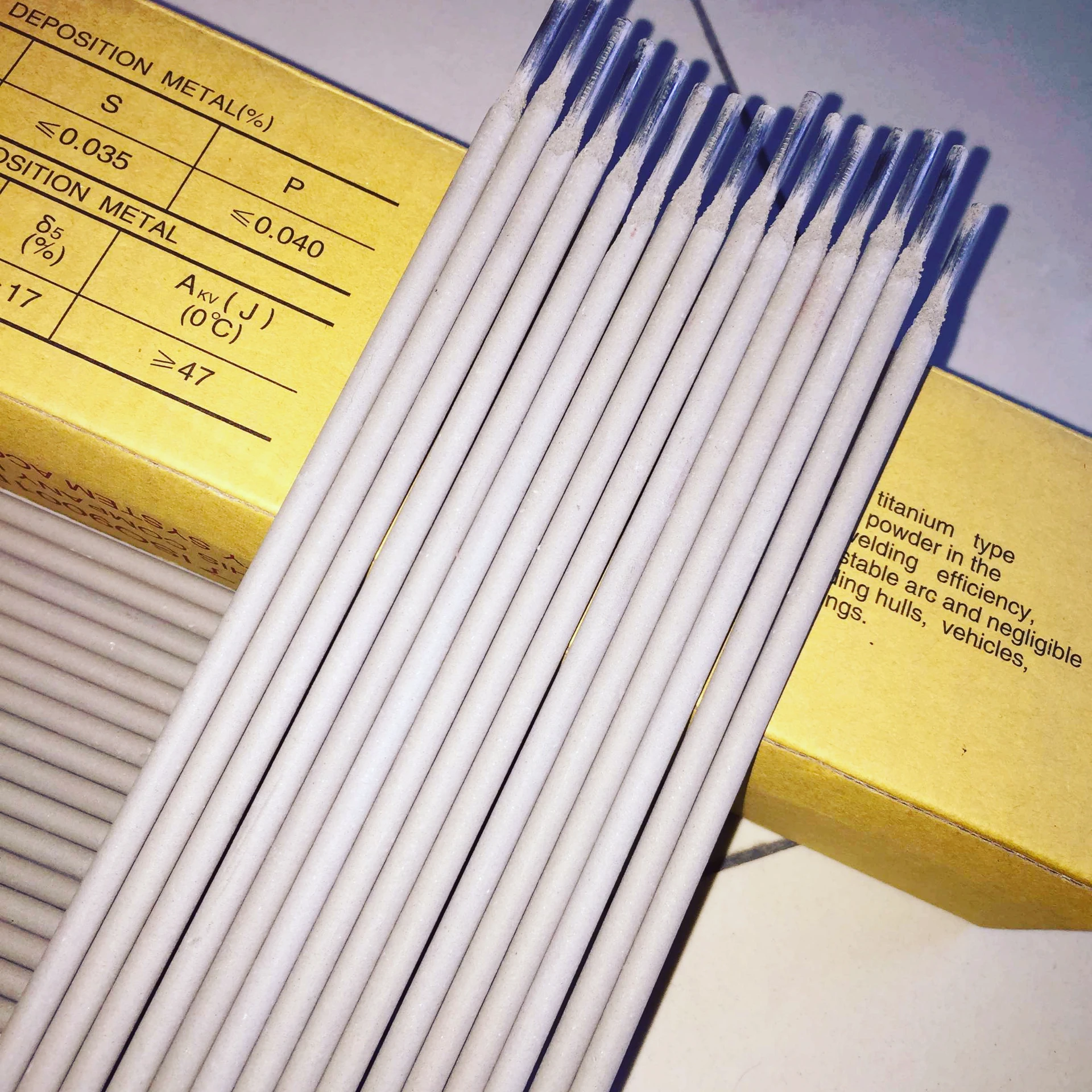

The welding rod is a melting electrode coated with welding rod arc welding flux, which consists of flux and welding core.Lees meer

The welding rod is a melting electrode coated with welding rod arc welding flux, which consists of flux and welding core.Lees meer -

In a chilling reminder of the perils associated with unlicensed operation, an accident at the 8-story staff dormitory construction site of a certain unit underscores the critical importance of skilled labor and stringent adherence to safety protocols.Lees meer

In a chilling reminder of the perils associated with unlicensed operation, an accident at the 8-story staff dormitory construction site of a certain unit underscores the critical importance of skilled labor and stringent adherence to safety protocols.Lees meer -

Select the appropriate welding current value according to factors such as the type of welding rod.Lees meer

Select the appropriate welding current value according to factors such as the type of welding rod.Lees meer -

High-altitude welding operations carry inherent risks that demand stringent safety measures to prevent accidents.Lees meer

High-altitude welding operations carry inherent risks that demand stringent safety measures to prevent accidents.Lees meer