Jan . 29, 2025 03:27

Back to list

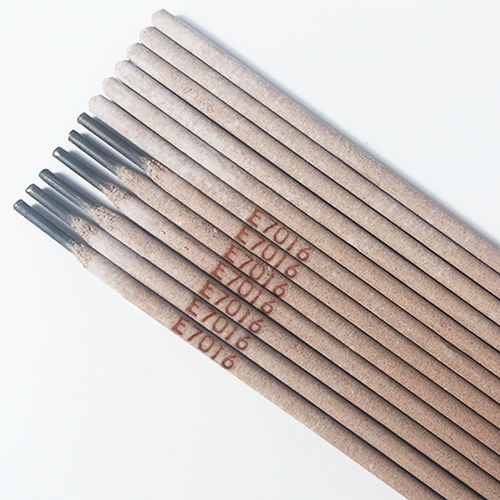

carbon steel welding rod

The 308-16 welding rod, a crucial tool in the arsenal of any welding professional, is revered for its exceptional properties, especially when it comes to working with stainless steel. This electrode is specifically engineered to weld austenitic stainless steels, containing a balanced amount of chromium and nickel, making it the go-to choice for projects requiring high corrosion resistance and strength. Let us delve into the multifaceted aspects of the 308-16 welding rod to understand why it holds such esteem among experts.

Trustworthiness is demonstrated by the consistent results it delivers time and again, a quality that has earned it long-term loyalty among professionals. When embarking on projects where the aesthetic finish is as crucial as the structural integrity, such as in architectural steel applications, the 308-16 rod is favored for its ability to create clean, visually appealing welds. Its user-friendly handling characteristics ensure that even lengthy welds can be executed with minimal fatigue and high confidence in end results, which reinforces its standing as a reliable tool. Furthermore, the rod's adaptability for both AC and DC welding currents renders it an all-purpose choice, greatly increasing its value in workshops where different machines and power supplies might be in use. The 308-16 is known for its low hydrogen content, which is critical for preventing weld cracking and improving overall weld quality. This feature increases the dependability of the welds in critical applications, such as in the automotive and aerospace industries, where precision is non-negotiable. Moreover, storage and longevity are factors where the 308-16 welding rod displays superiority. Its flux coating guards against moisture absorption, thereby reducing the risk of hydrogen-induced defects which can compromise weld quality. Regular assessments and feedback from industry veterans show that this electrode can sustain its efficacy over time when stored under optimal conditions — a significant economy for enterprises focused on cost-cutting without compromising quality. In conclusion, the 308-16 welding rod stands as a paragon of strength and durability in the welding industry, encapsulating the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. For those in search of a welding solution that ensures top-tier performance across a variety of metals and conditions, this welding rod consistently emerges as a prime candidate. Whether it’s creating fabrications meant to withstand harsh environments, achieving impeccable finishings, or ensuring safety and compliance, the 308-16 delivers, every time. As such, it not only meets but exceeds the demands of today's meticulous welding standards, securing its place as a favorite among professionals worldwide.

Trustworthiness is demonstrated by the consistent results it delivers time and again, a quality that has earned it long-term loyalty among professionals. When embarking on projects where the aesthetic finish is as crucial as the structural integrity, such as in architectural steel applications, the 308-16 rod is favored for its ability to create clean, visually appealing welds. Its user-friendly handling characteristics ensure that even lengthy welds can be executed with minimal fatigue and high confidence in end results, which reinforces its standing as a reliable tool. Furthermore, the rod's adaptability for both AC and DC welding currents renders it an all-purpose choice, greatly increasing its value in workshops where different machines and power supplies might be in use. The 308-16 is known for its low hydrogen content, which is critical for preventing weld cracking and improving overall weld quality. This feature increases the dependability of the welds in critical applications, such as in the automotive and aerospace industries, where precision is non-negotiable. Moreover, storage and longevity are factors where the 308-16 welding rod displays superiority. Its flux coating guards against moisture absorption, thereby reducing the risk of hydrogen-induced defects which can compromise weld quality. Regular assessments and feedback from industry veterans show that this electrode can sustain its efficacy over time when stored under optimal conditions — a significant economy for enterprises focused on cost-cutting without compromising quality. In conclusion, the 308-16 welding rod stands as a paragon of strength and durability in the welding industry, encapsulating the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. For those in search of a welding solution that ensures top-tier performance across a variety of metals and conditions, this welding rod consistently emerges as a prime candidate. Whether it’s creating fabrications meant to withstand harsh environments, achieving impeccable finishings, or ensuring safety and compliance, the 308-16 delivers, every time. As such, it not only meets but exceeds the demands of today's meticulous welding standards, securing its place as a favorite among professionals worldwide.

Previous:

Next:

Latest news

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025